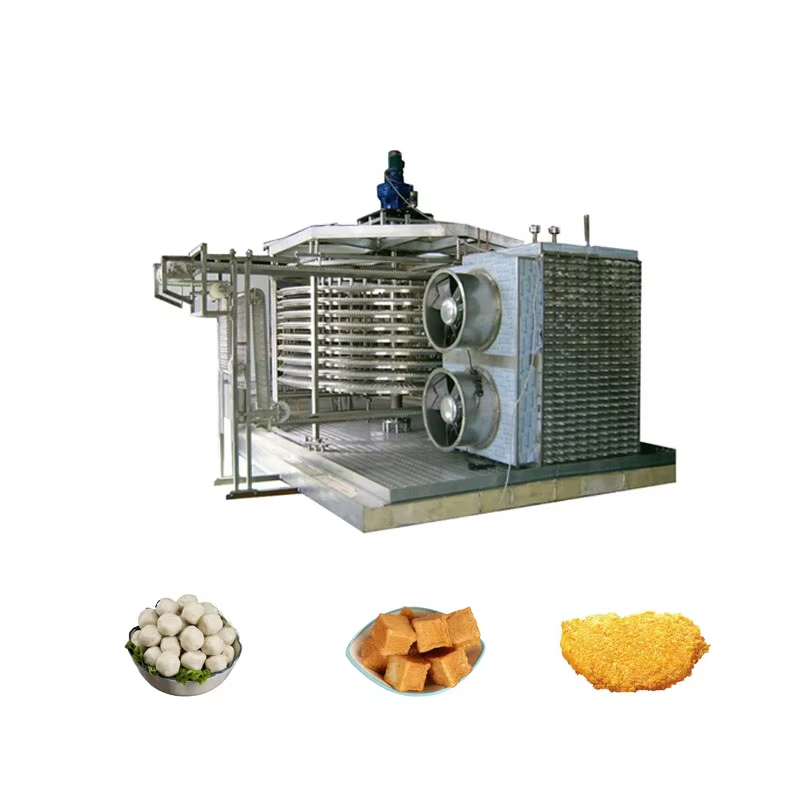

Prispôsobiteľnosť pre rôzne druhy a produkty rýb

Náš strojní park môže spracovávať rôzne druhy ryb, ako sú tuňak alebo sardíny, a ponúka tiež rôzne typy filetov, celé ryby a dokonca aj produkty so zvýšenou hodnotou, ako sú kuřaté alebo namäkané ryby, všetko díky našim spracovným linkám. Napríklad, odmaľovanie a vyčistenie celých rýb sa dá prepnúť na výrobu bezkostných filetov za niekoľko minút. Švieži aj zmrazené ryby sa dajú tiež spracovať, keďže stroje sú vybavené integrovanými rozmrazovacími tuneľmi pre zmrazené suroviny. Tento druh univerzality umožňuje spracovateľom pridať nové morské produkty do svojich ponúk, čím zlepšia návratnosť investícií, pretože nemusia kupovať veľa samostatných strojov.