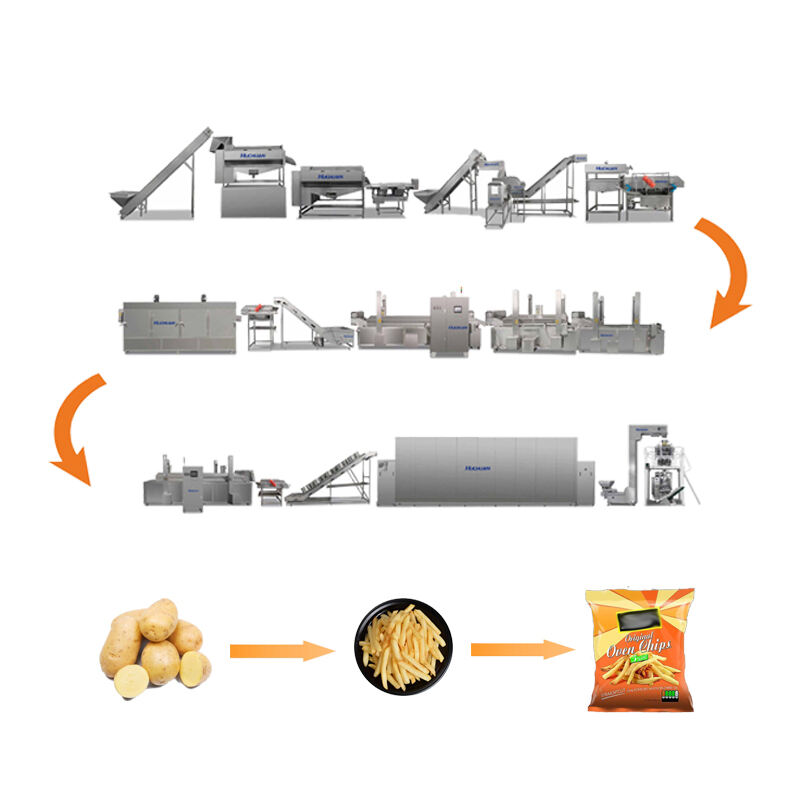

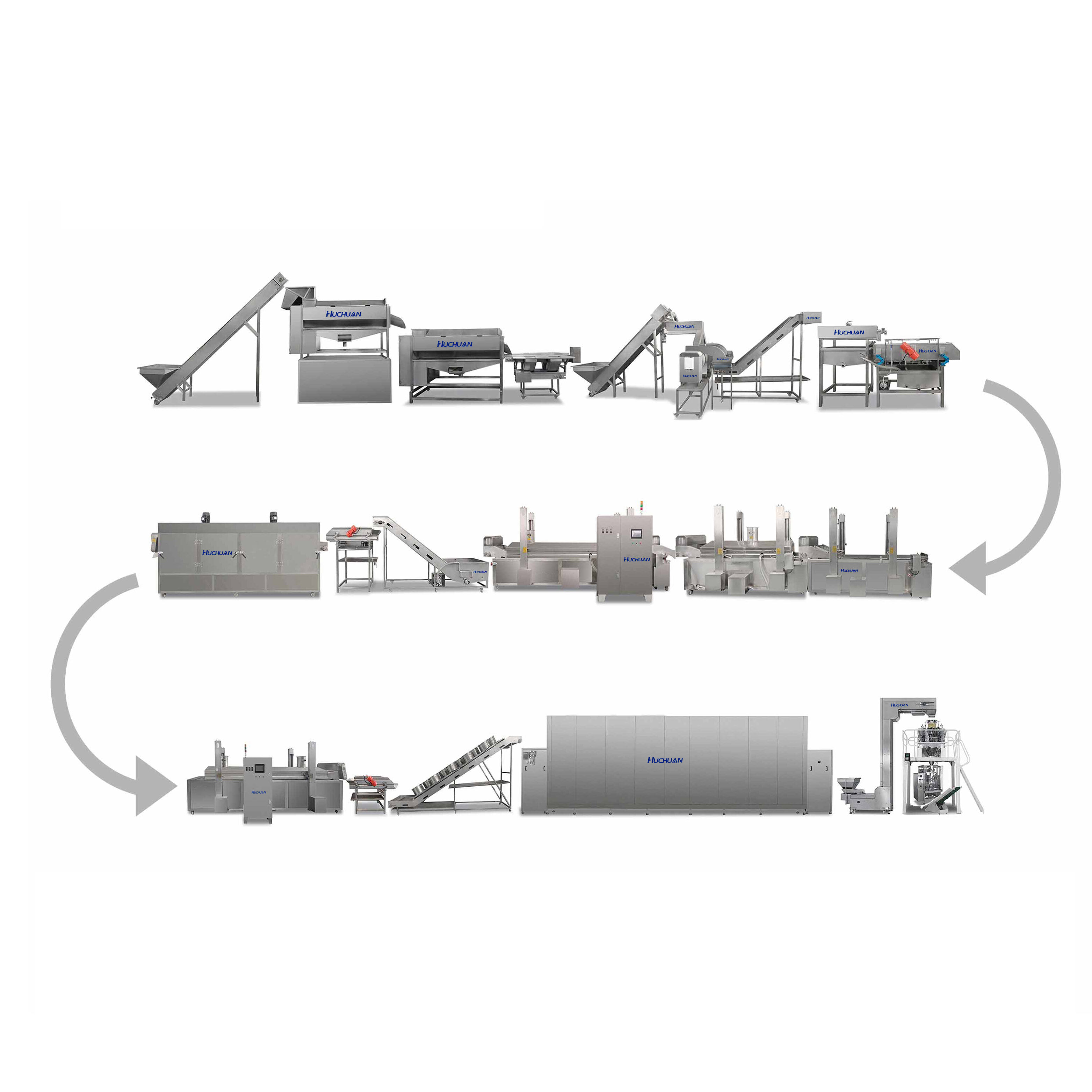

Толук автоматты француз чыбындын өндүрүү сызыгы көп жыштыктагы урууга дагы азгынча адамдын катышуусу менен кармап, тазалоодон баштап, даяр чыбын мүзгө түшүрүлгөн же оролгон түрдө чыгарууга чейинки бардык этаптарды камтыйт. Бул системаны орто жана чоң көлөмдө иштетүүчүлөр (быстрфуд түрмөлөрүнө, бөлчө сүмүшкө) күнүнө 500–2000 кг чыгымы менен колдонушат. Ал жылдамдыкты, бирдемдүүлүктү жана тамак-аштын коопсуздугун камсыз кылып, бирдей чыбынга болгон суроону канааттандырат, текстураны (тыгыз сырты, жумшак ичин) сактайт жана чыгындарды кемитет. Сызыктын иш процеси үзгүлтүксүз жана автоматты: түпкү картоп көп бөлмөлүү ыдыкка түшүрүлөт, андан арткан тазалоо ыдыгына (айлануучу щеткалар + жогорку басымдагы суу) ташытылат. Дагы бир түрү – таштарды картоптон ажыратуу системасы (суунун тыгыздыгын колдонуп), бул жабдуунун зыян келтирилиши менен тамак-аштын коопсуздугун камсыз кылат. Тартуу үчүн булгануу системасы (100–105℃ булак менен 40–60 секунд) же механикалык тарткычтар (абразивды роликтер) колдонулат, картоптун түрүнө жараша – булгануу щадящий түрү (чыгын <5%) жогорку сапаттуу чыбын үчүн, ал эми механикалык тартуу чоң көлөмдө иштөө үчүн арзан. Тартылгандан кийин картоп оптикалык сорттолгуч менен текшерилип, кемчиликтери (коюлуп калуу же көз) бар картоптор алынып салынат. Кесүү модулу бир нече пышактуу айлануучу кесүү куралын (пышак аралыгын 6–12 мм стандарт чыбын үчүн, 10–15 мм калын чыбын үчүн) жана артык крахмалды жууп түрбөтүүчү суу шлангын колдонот – бул чыбын бирикпей калышы үчүн жана бирдемдүү күйүп чыгышы үчүн маанилүү. Крахмалды жумшатуу – сапатты камсыздоонун негизги этапы: чыбын 80–90℃ сууга 2–3 мүнөттө батырып, крахмал жумшатылат (крустты жакшыртат) жана ферменттер активдүүлүгү токтотулат (түстүн көңүртөшүнө каршы). Салкындатуу транспортери (сууну салкындатуу, 0–5℃) пайдаланылат, андан кийин сууну алуу системасы (ауа үрткүчтөрү же сүзгүчтөр) бетинде калган сууну алып салат. Мүзгө түшүрүлгөн чыбын үчүн сызык IQF (Individual Quick Freezing) туннелди колдонот (-35℃ ден -45℃ чейин, 8–12 мүнөт морозилкалоо убактысы), чыбынды жеке морозилкалоо үчүн, алар бири-бирине жабышпайт. Даяр чыбын үчүн, үзгүлтүксүз фритюрница (175–190℃ өсүмдүк майы, 2.5–3.5 мүнөт күйгүзүү убактысы) колдонулат, ички май фильтрация системасы тамак бөлүктөрүн алып салуу үчүн жана майдын сапатын сактоо үчүн. Майдан ары кылуу (сүзгүч же ауу менен) майдын мөөнөтүн 15–20% чейин кемитет. Опактоо толук автоматты: мүзгө түшүрүлгөн чыбын автоматты түрдө өлчөнүп, ылгакка каршы чанчаларга (100–150 CPM) же картон коробкаларга түшүрүлөт, даяр чыбын үчүн модификацияланган атмосфералык опактоо (MAP, 70% N₂, 30% CO₂) колдонулат, ал сактоо мөөнөтүн 5–7 күнгө чейин узартат. Сапаттын башкаруусу бүтүндөй камтылган: металл детекторлор, чеквесы (±1 грамм тактыгы) жана герметикалык текшерүү куралдары тамак-аштын коопсуздугу стандарттарына (FDA, EU 1333/2008) туура келет. Бардык тамак-аш менен тийишкен бөлүктөр 304 нержавеющая кооз болот, CIP системалары аркылуу автоматты түрдө жуулуп турат, чыгышынан каршы күрөшүлөт. Иштетүүчүлөр үчүн, бул сызык чыбындын өлчөмүн, текстураны жана дарыянын бирдемдүүлүгүн камсыз кылат (партиядан-партияга өзгөрүү <2%), быстрфуд түрмөлөрүнүн талаптарын (мисалы, чыбын чыгаруучу куралдар үчүн бирдей узундук) жана чоң суроо убактысын (мисалы, жаңы жыл мерекеси) колдойт.

Эчкенин түзмө © 2025 Шандонг Кангбейте Буйук Азырланышын Басып Чыгаруу Машиналары Co., Ltd. Купуялык Саясаты