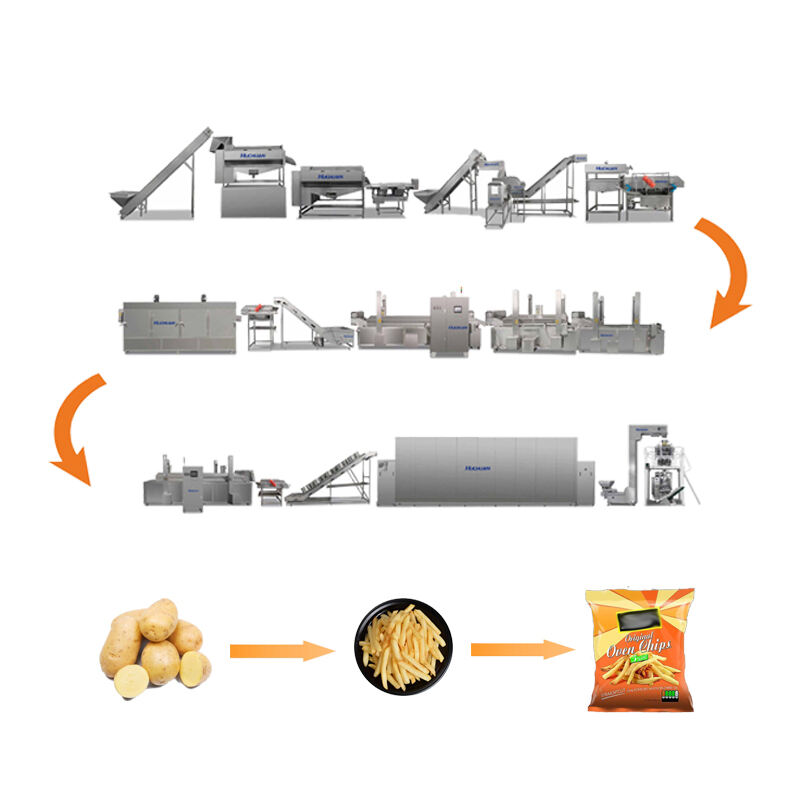

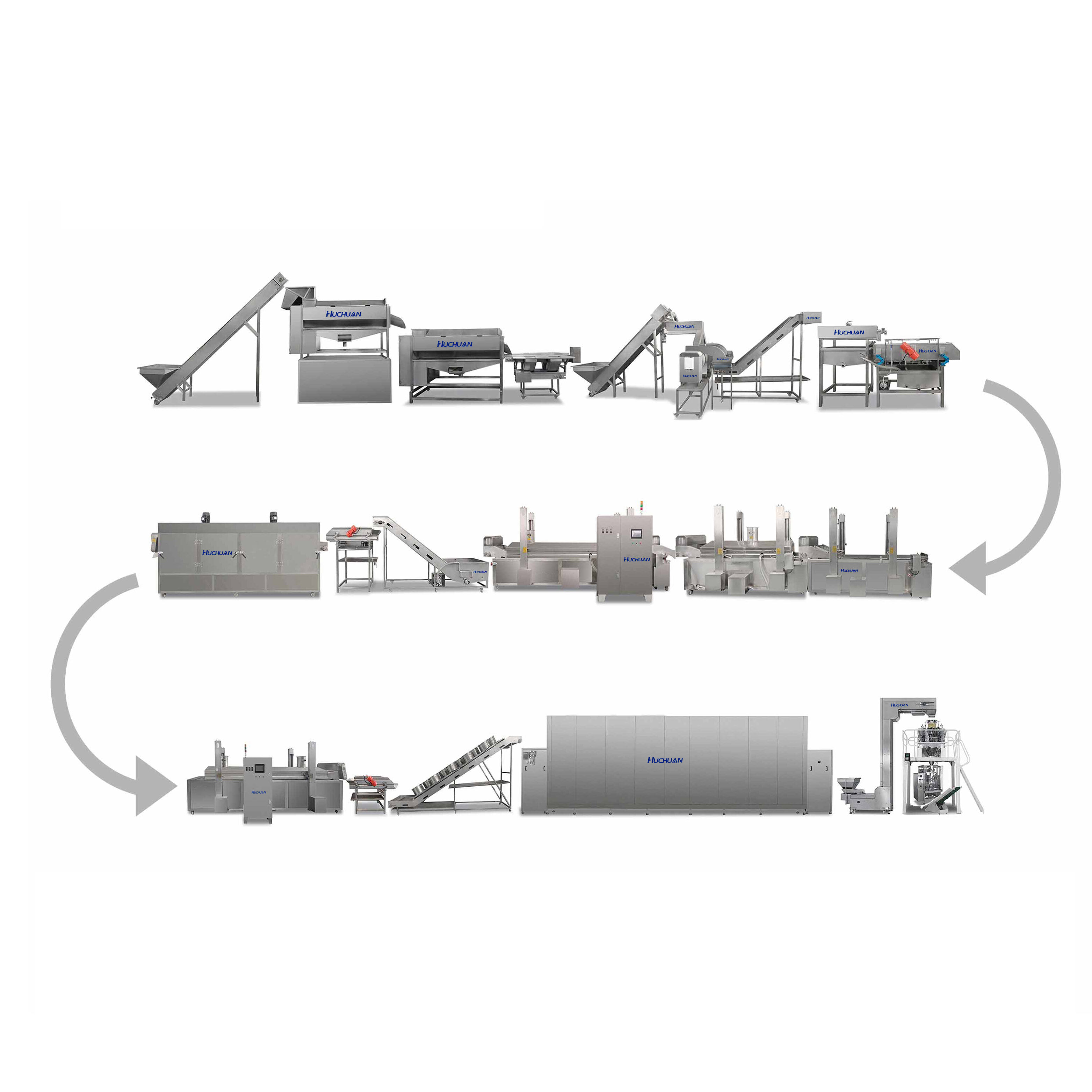

KANGBEITE тарабынан иштеп чыгарылган чыгышкан картоп чыгаруу сызыгы таттуу ойуточкуларга болгон суранымды көбөйтүү үчүн жасалып, автоматтандыруу менен так тактоо бириктирилген, бирдей таттуу продукт чыгарууга мүмкүнчүлүк берет. Стандарттуу толук автоматтык сызыктан турган негизине кошумча тат кошуу модулун кошуп, ар бир картоптун бирдей татталышын камсыз кылат. Картоп чычкандан жана суу салгандан кийин, алар өзгөрүп турган башка бөлүмгө же тербелмелүү конвейерге түшөт, анда таттар – классикалык туз жана сырдан баштап, чили лайм же барбекю сыяктуу аймактык сүйүктүүлөргө чейин – кармалат. Система өзгөрмө ылдамдык контролдорун жана таттарды чачуу куралдарын колдонуп, ар кандай бөлүкчөлөргө бейимделет, түйүлдүрүлүштүн алдын алып, 100% капталышын камсыз кылат. Сызыкка киргизилген сапат датчиктери таттын тыгыздыгын көзөмөлдөп, операторлорго айырмачылыктар жөнүндө эскертүү берет жана партиялардын бирдемдүүлүгүн сактайт. Тез алмаштыруучу хопперлор таттардын рецеттери ортосунда чексиз өтүүнү камсыз кылып, бир нече таттарды бир эле вахтада чыгарууга мүмкүнчүлүк берет – бул Азия үчүн тузгунттууларды же Европа үчүн түтүндүү таттарды максат кылуу үчүн идеалдуу. Тат кошуу процесстин өзү жабык системада иштейт, чачылган чалгын менен чалындынын алдын алып, тамак-аш коопсуздугу боюнча катагорияларга (CE, ISO9001 2015) жана глобалдык ден соолук талаптарына ылайык келет. Сызыктардын долбоору гигиенаны негиздейт, тазалоого жеңил беттер менен коррозияга туруктуу болгон болот куралдары менен, таттардын аралашып кетүүсүнө жол бербейт. Тат кошулгандан кийин картоптар көбүнчө MAP технологиясын колдонуу менен уячкаларга жеткизилет. KANGBEITE техникалык командасы рецеталарды оптимизациялоо боюнча жеринде окутуу жүргүзөт, пайдалануунун узак мөөнөтүн камсыз кылат. 100дөн ашык өлкөгө экспорттолгон бул сызык бренддерге түрдүү таттарды сүйүүчүлөрдүн талаптарын канааттандыруу үчүн өз продукттарынын ассортиментин кеңейтүүгө мүмкүнчүлүк берет.

Эчкенин түзмө © 2025 Шандонг Кангбейте Буйук Азырланышын Басып Чыгаруу Машиналары Co., Ltd. Купуялык Саясаты