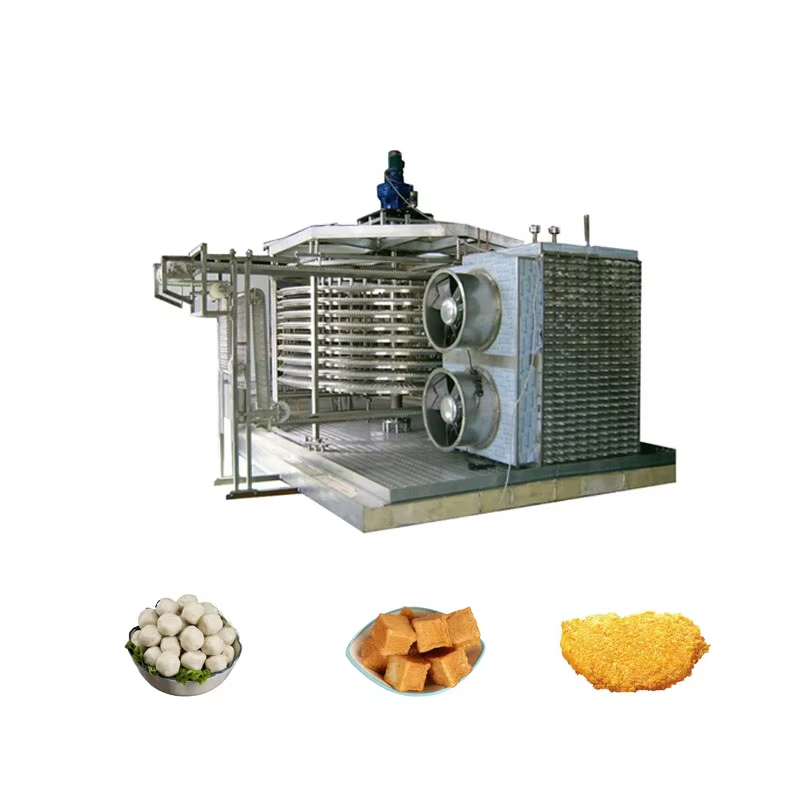

Линия за преработка на замразена риба е комплексна, непрекъсната система, предназначена да превръща прясна или частично замразена риба в продукти с добавена стойност (напр. замразени филета, порционна риба, панирани пълчета или цяла замразена риба), като се запазва качеството, безопасността и съответствието с международните стандарти за морски дарове. Използвана от големи производители на морски продукти и предприятия за производство на замразени храни, тази линия решава специфичните предизвикателства при преработката на замразена риба – предотвратяване на изгаряне от мраз (губене на влага), запазване на текстурата (избягване на разрушаване на клетките от ледени кристали) и осигуряване на микробиологична безопасност (потискане на патогени като Listeria monocytogenes или Salmonella) през целия процес. Основни модули на линията за преработка на замразена риба включват: зона за размразяване (за частично замразена риба – използвайки вода с ниска температура или въздушно размразяване, за да се доведе рибата до температура между -2°C и 0°C, оптимална за обработка без пълно размразяване, което запазва текстурата), станция за почистване (с високонапорни водни струи и четки за премахване на слуз, кръв и люспи, с възможност за озонова дезинфекция), модул за почистване на вътрешности и отрязване на глави (автоматични ножове или механични системи за премахване на вътрешности, глави и пера – персонализирани според вида риба, например кръгли ножове за малки риби, хидравлични системи за големи риби като тон), модул за филетиране (прецизни ножове или водни струи, които разделят месото от костите, с детектори на кости (използващи рентген или сензори в близкия инфрачервен диапазон) за премахване на останали кости – критично за безопасността на храната), станция за подрязване (премахване на мазнини, кожа или дефектни части, за да се осигурят еднакви филета), модул за порциониране (рязане на филета на стандартни размери (напр. 100 г, 200 г) с въртящи се ножове или ултразвукови резачки), зона за паниране или покритие (за продукти с добавена стойност – нанасяне на хлябни трохи, тесто или подправки чрез електростатично покритие или системи с транспортьори), тунел за замразяване (използваща технологията IQF (Индивидуално бързо замразяване) с температура на въздуха между -35°C и -45°C, за да се замразят продуктите бързо, предотвратявайки формирането на ледени кристали, или криогенно замразяване с течен азот за ултрабързо замразяване на деликатни филета) и линия за опаковане (автоматични системи, които запечатват продуктите в опаковки с висока защита от влага и кислород (напр. вакуумни торбички или кутии) за предотвратяване на изгаряне от мраз и удължаване на срока на годност, с етикети за проследяване (номер на партида, дата на улов, произход)). При избора на материали се предпочитат издръжливост и безопасност: всички повърхности, които се допират до рибата, са от неръждаема стомана 316 (устойчива на корозия от солена вода и рибни киселини), а транспортьорите са произведени от хранителен PU или тефлон (антиприлепващи, лесни за почистване). Хигиената се подобрява чрез системи за почистване на място (CIP), гладки повърхности и отделни зони за сурова и обработена риба (за предотвратяване на кръстосано замърсяване). Енергийната ефективност включва възстановяване на топлина (събиране на студен въздух от замразителите за предварително охлаждане на новата риба) и компресори с променлива скорост. Системите за управление са напреднали, с програмируеми логически контролери (PLC) и HMI (интерфейс човек-машина) екрани, които следят параметрите на обработката (време на замразяване, температура, размер на порцията) и записват данни за съответствие с HACCP, FDA и EU регулациите. Производителността варира от 1000–5000 кг/ч за средни линии до над 10 000 кг/ч за индустриални операции. За международни пазари линиите са сертифицирани по стандарти като MSC (Съвет по опазване на моретата) за устойчиво набавяне и BRCGS за безопасност на храните. В заключение, линията за преработка на замразена риба позволява на производителите да изработват постоянни, безопасни и висококачествени продукти от замразена риба в големи обеми, отговаряйки на потребителското търсене за удобни и с дълъг срок на годност морски дарове, като същевременно се съобразяват с най-строгите международни регулации.

Права на автор © 2025 от firma Shandong Kangbeite Food Packaging Machine Co., Ltd. Политика за поверителност