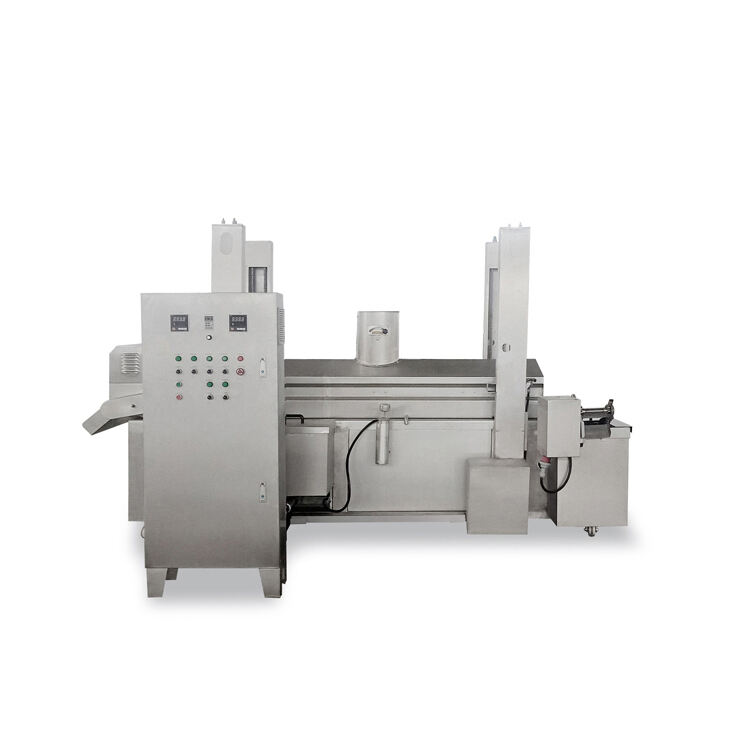

A multi-function frying machine is a versatile piece of equipment designed to meet diverse frying needs across the food processing industry, making it a staple for both small-scale food businesses and large manufacturing facilities. Unlike single-purpose fryers that only handle specific food types, this machine integrates multiple capabilities to fry a wide range of products, including French fries, chicken nuggets, onion rings, tempura, doughnuts, and even vegetable snacks—all while maintaining consistent quality and operational efficiency. Its core design features typically include adjustable temperature controls (ranging from 120°C to 220°C, catering to different frying requirements), variable frying time settings, and interchangeable baskets or conveyor belts that adapt to various food shapes and sizes. Many advanced models also incorporate oil filtration systems to extend oil lifespan, reducing operational costs and ensuring food safety by minimizing oil degradation. Additionally, some units come with dual or multiple frying chambers, allowing simultaneous frying of different products without flavor cross-contamination—a critical advantage for food facilities aiming to boost productivity and diversify their product lines. From a technical standpoint, the machine’s heating systems (often electric, gas, or infrared) are engineered for uniform heat distribution, preventing hot spots that can lead to unevenly fried food (e.g., undercooked centers or overburnt exteriors). Safety features are also prioritized, such as heat-resistant handles, automatic oil level monitoring, and emergency shut-off systems to comply with industry safety standards. For businesses, investing in a multi-function frying machine translates to space optimization (replacing multiple single-use fryers with one unit), labor savings (simplified operation and reduced need for dedicated staff for each fryer), and enhanced flexibility to respond to changing market demands—whether it’s seasonal snacks or new product launches. In global markets, this equipment is adapted to different voltage standards (e.g., 110V for North America, 220V for Europe and Asia) and fuel preferences, ensuring compatibility with local infrastructure. Overall, the multi-function frying machine stands out as a cost-effective, efficient, and adaptable solution that aligns with the dynamic needs of modern food processing operations, supporting businesses in delivering high-quality fried products while maximizing resource utilization.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy