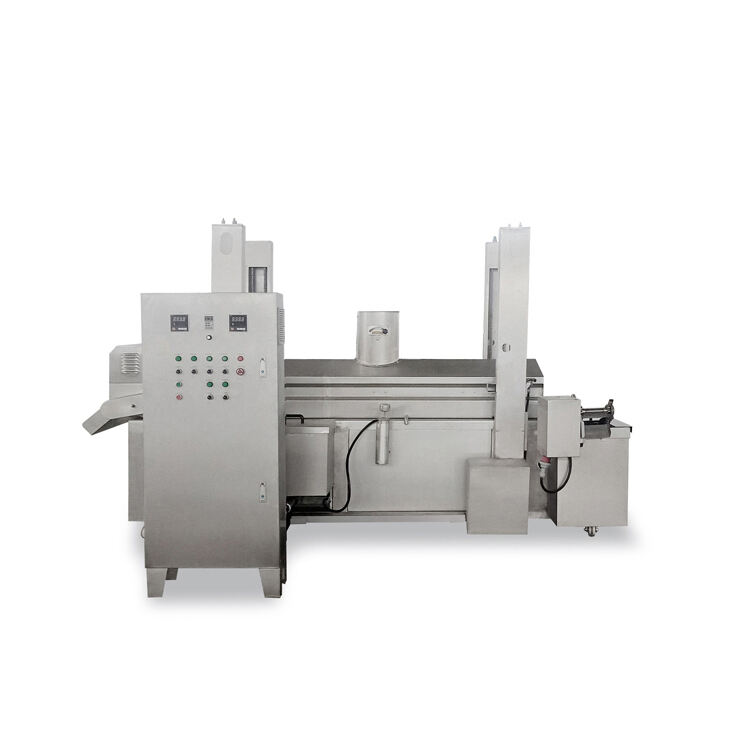

A design that needs little maintenance and is energy saving

A conventional model a frying machine uses thin jackets for thermal protection which makes their ovens inflate and expand equally these using spacer ovens to collide the heat energy into each other in overlap convention to and reduce energy needed by 25%.

The low-noise their pumps and motors( ≤ 75 dB) are within the limits of occupational health and safety, while self-cleaning oil tanks and detachable conveyor belts are helpful for maintenance. Corrosive Stainless steel construction is extremely acidic. food resistant which allows for 10 years of life with little wear and tear. For small to medium enterprises, semi-automatic variants are available which provide 40% energy savings at a professional operating level.