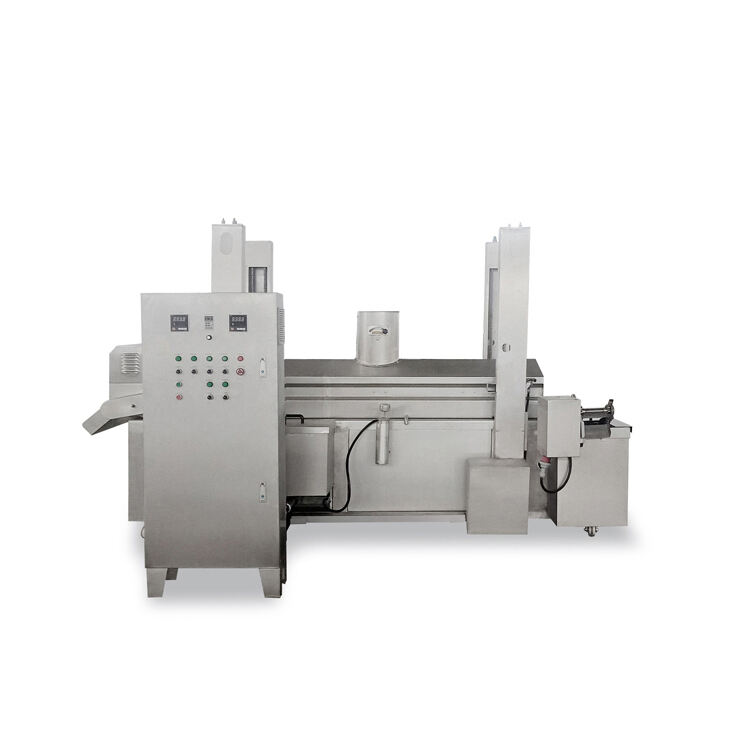

KANGBEITE's commercial frying machines are designed to meet the rigorous demands of commercial food establishments, such as restaurants, fast food chains, catering services, and small to medium scale food processing plants. These machines are engineered to provide consistent, high quality frying performance while being durable, easy to operate, and maintain. One of the primary considerations in the design of commercial frying machines is capacity. KANGBEITE offers a variety of models with different frying capacities, ranging from small batch fryers suitable for quick service restaurants that need to fry a limited number of items at a time to large capacity fryers for high volume food production. The frying chambers are made from high quality, food grade stainless steel, which is resistant to corrosion and easy to clean, ensuring hygiene and longevity. Temperature control is crucial in commercial frying, and these machines are equipped with precise temperature control systems. Whether it's a simple dial based control for basic models or an advanced digital control panel with programmable settings for more sophisticated fryers, operators can easily set and maintain the desired frying temperature. This allows for consistent frying results, ensuring that the food is cooked to perfection every time. Commercial frying machines also feature efficient oil management systems. Some models come with built in oil filtration systems that help to remove food particles and

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy