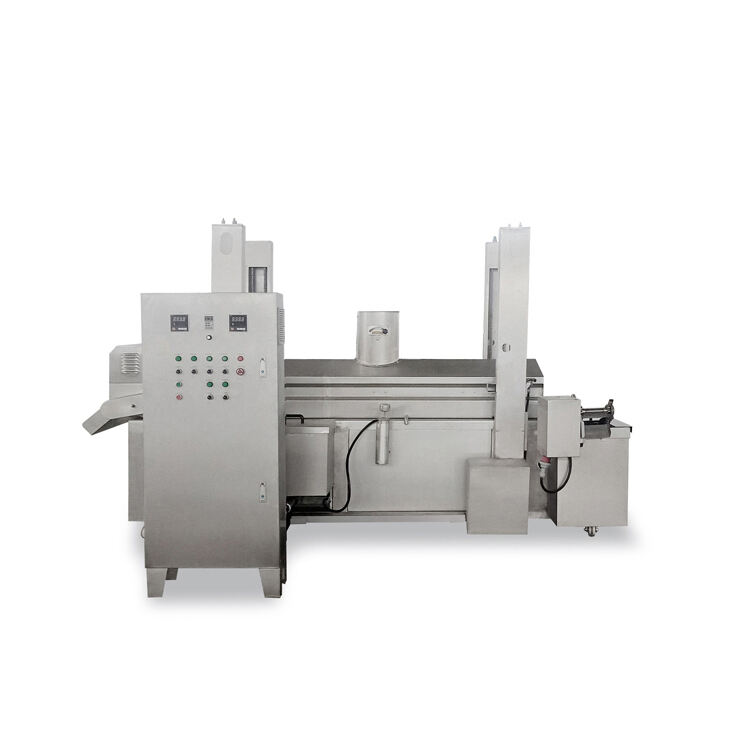

An even heating frying machine is a type of frying equipment that can evenly distribute heat during the frying process to ensure the uniform frying of food, thereby improving the quality and taste of fried products. It usually adopts a reasonable heating element design and heat conducting structure. For example, some frying machines use U shaped stainless steel heating tubes, which can make the heat spread more evenly in the oil, avoiding local over heating or under heating phenomenon. This is very important for frying foods, because uneven heating can lead to inconsistent frying degrees of food, some parts are over fried and become black and bitter, while some parts are not cooked through. In addition, some even heating frying machines are equipped with automatic stirring functions. The stirring device can continuously turn the food during the frying process, so that each part of the food can be evenly exposed to the hot oil, further ensuring the uniformity of frying. This is especially suitable for frying large sized or irregularly shaped foods. The temperature control system is also a key part of the even heating frying machine. It can accurately control the oil temperature to keep it within a suitable range. Usually, the temperature control range is wide, which can be adjusted according to different types of food, such as frying potatoes may require a lower temperature, while frying chicken pieces may need a higher temperature. Some high end frying machines also have functions such as temperature rise reminder and over temperature protection, which not only improve the frying effect but also ensure the safety of equipment operation. Moreover, the materials used in the frying machine are usually food grade stainless steel, which is not only corrosion resistant and easy to clean but also meets food safety standards, ensuring that there will be no harmful substances released during the frying process.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy