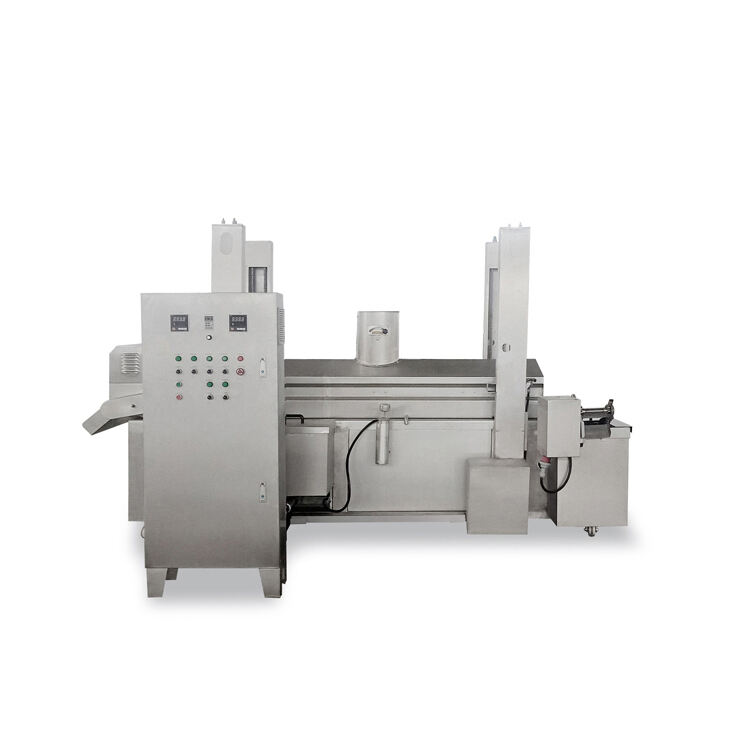

Speedy Industrial Process

The degree of efficiency incorporated in our machines are unmatched as they fully automate a product’s frying line and can achieve 1000kg/h of varied products from French fries to chicken nuggets. The modular construction along with the battering/breading systems make the order to work downstream with coolers and conveyors. The spiral or tunnel shapes allow for operating without breaks for example the time required to shift from frying potato chips to frying onion rings is only 15 minutes with the use of quick-change oil tanks and very minimal adjustment to the conveyor. This creates flexibility for fast food vendors and snack food industrials.