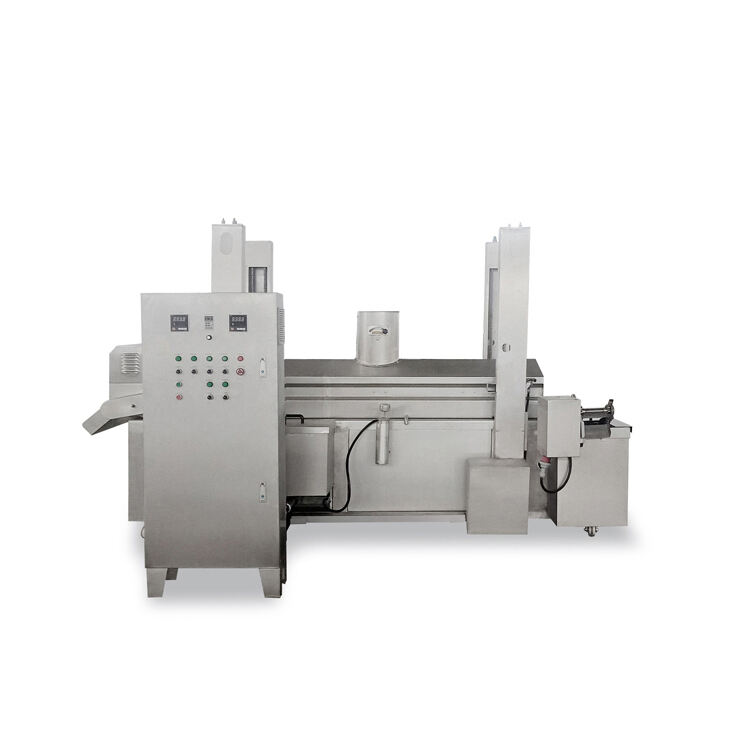

A CE certified frying machine is a frying equipment that has obtained CE certification, which means that the machine meets the relevant safety, health, and environmental protection requirements in the European Union market. Firstly, in terms of safety, CE certified frying machines are equipped with a series of safety protection devices. For example, they have over temperature protection functions, which can automatically cut off the power supply when the oil temperature exceeds the set value to prevent the occurrence of fire and other accidents caused by over heating. There are also leakage protection devices to ensure the safety of operators when there is an electrical leakage problem. In addition, the shell of the frying machine is usually made of insulating materials to prevent operators from being electrocuted. In terms of health, the materials used in CE certified frying machines are all in line with food grade standards, usually using high quality stainless steel, which is non toxic, harmless, and easy to clean. This can prevent harmful substances from migrating into food during the frying process, ensuring food safety. The internal structure of the frying machine is also designed to be conducive to cleaning, with no dead corners, so as to avoid the residue of food debris and oil stains, reducing the growth of bacteria. In terms of environmental protection, CE certified frying machines usually pay attention to energy saving and emission reduction. Some frying machines adopt advanced heating technologies and heat preservation structures to reduce energy consumption, such as using efficient burners and high quality heat preservation materials, which can not only save energy but also reduce the emission of waste gas, meeting the environmental protection requirements of the European Union market and also helping enterprises to reduce production costs in the long run.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy