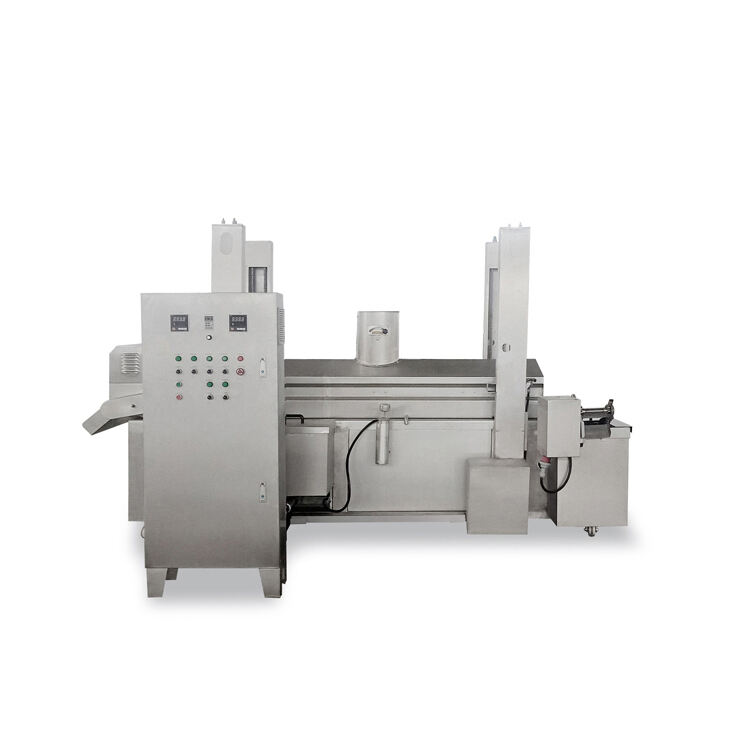

A gas powered frying machine is a frying equipment that uses gas as a heating source. It has the advantages of high heating efficiency, low cost, and convenient operation, and is widely used in the food processing industry. The gas powered frying machine usually uses natural gas or liquefied petroleum gas as fuel. Through a special burner, the gas is burned to generate heat, and the heat is transferred to the oil in the frying pan, so as to realize the frying of food. Compared with electric heating frying machines, gas powered frying machines have a faster heating speed, which can save pre heating time and improve production efficiency. For example, in some large scale food processing plants, gas powered frying machines can quickly heat a large amount of oil to the required temperature, meeting the needs of continuous production. In addition, the cost of gas is relatively low, which can reduce the production cost of enterprises. Especially for some enterprises with large scale production, the cost saving effect is more obvious. The temperature control of gas powered frying machines is also relatively flexible. By adjusting the gas flow, the heating power can be adjusted, so as to accurately control the oil temperature. Most gas powered frying machines are equipped with a temperature control system, which can set and monitor the oil temperature to ensure the stability of the frying process. The structure of gas powered frying machines is usually relatively simple, which is convenient for maintenance and repair. However, safety measures need to be taken into account during use, such as installing gas leakage detection devices and ensuring good ventilation to prevent gas leakage and explosion accidents. At the same time, the burner of the gas powered frying machine needs regular maintenance and cleaning to ensure its normal combustion and heating efficiency.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy