Onion Ring Frying Machines - Above Industry Standard Solutions

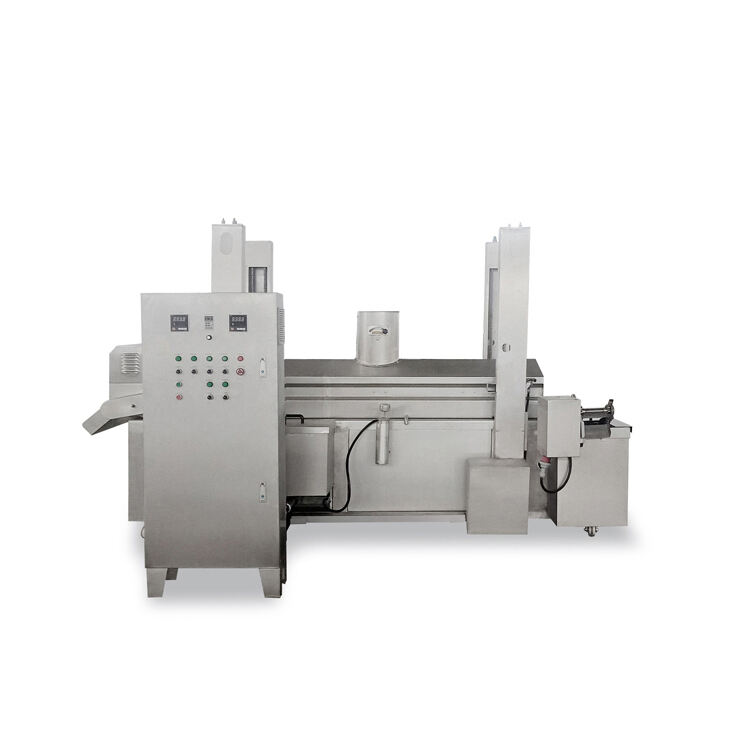

Our frying machines for onion rings are designed with production efficiency in mind. From small food stalls to big industrial outlets, they guarantee small-scale and large-scale consistent frying results. Continuous, batch, and basket types are available, all using easy-to-operate controls and constructed from food-safe materials.

Get A Quote