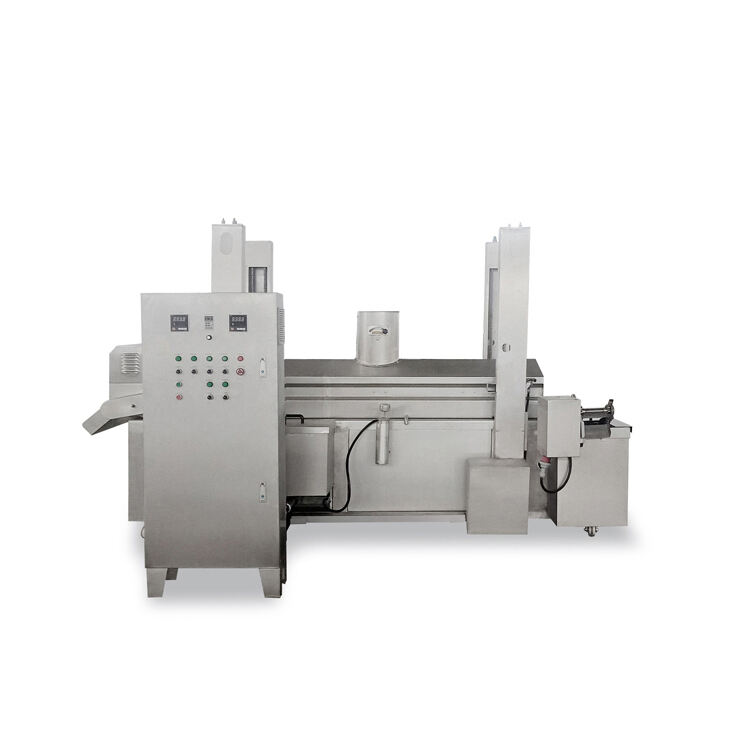

KANGBEITE's fully automatic frying machine is a technological marvel that streamlines the frying process, reducing manual labor and increasing productivity while maintaining high quality frying results. The machine operates with minimal human intervention, making it an ideal choice for large scale food production facilities, restaurants, and snack manufacturers. The operation of the fully automatic frying machine begins with the automatic feeding of food products. Conveyor belts or other automated feeding systems are used to transport the food items into the frying chamber. These feeding systems are equipped with sensors that can detect the presence and position of the food, ensuring accurate placement in the oil. Once the food is in the frying chamber, the machine automatically controls the frying process. Precise temperature control is a key feature of the fully automatic frying machine. Advanced temperature sensors continuously monitor the oil temperature, and the control system adjusts the heating elements in real time to maintain the desired frying temperature. This ensures that the food is fried evenly and to perfection, regardless of the batch size. The machine also features automatic stirring or flipping mechanisms, depending on the type of food being fried. These mechanisms ensure that the food is cooked uniformly on all sides, preventing uneven browning or under cooking. After the frying process is complete, the fully automatic frying machine automatically removes the fried products from the oil. This can be achieved through conveyor belts that lift the food out of the frying chamber or other extraction mechanisms. The fried products are then transported to a draining or cooling station, where excess oil is removed, and the products are prepared for packaging or further processing. The fully automatic frying machine is also equipped with safety features to protect operators and the equipment. Emergency stop buttons, safety guards, and automatic shut off systems in case of oil overheating or other malfunctions are standard features. The machine is constructed from high quality, food grade materials that are easy to clean and maintain, ensuring hygiene and compliance with food safety standards. With its seamless automation, precise control, and safety features, KANGBEITE's fully automatic frying machine offers a reliable and efficient solution for all frying needs.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy