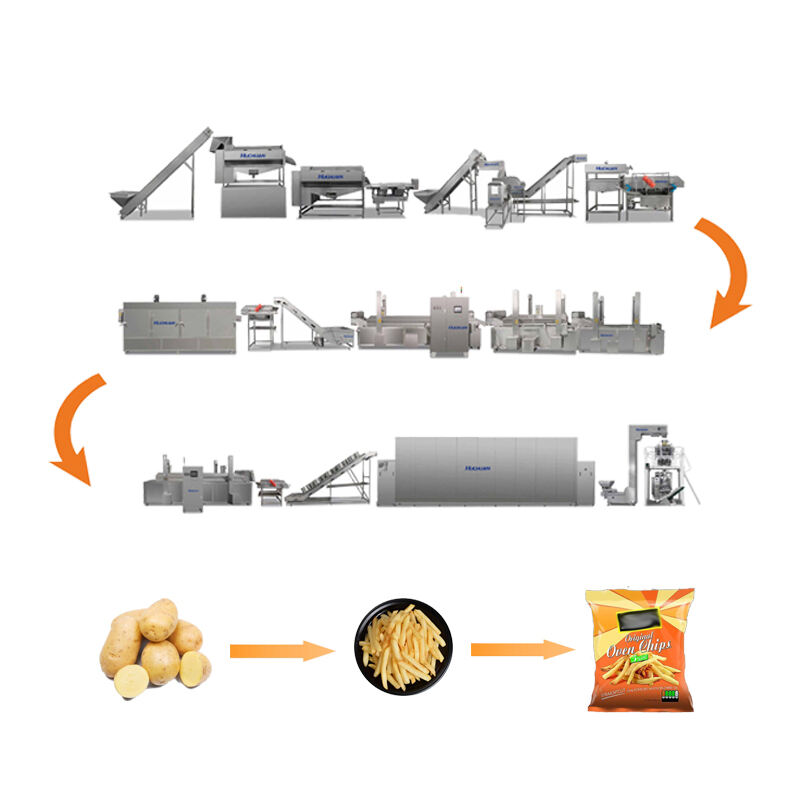

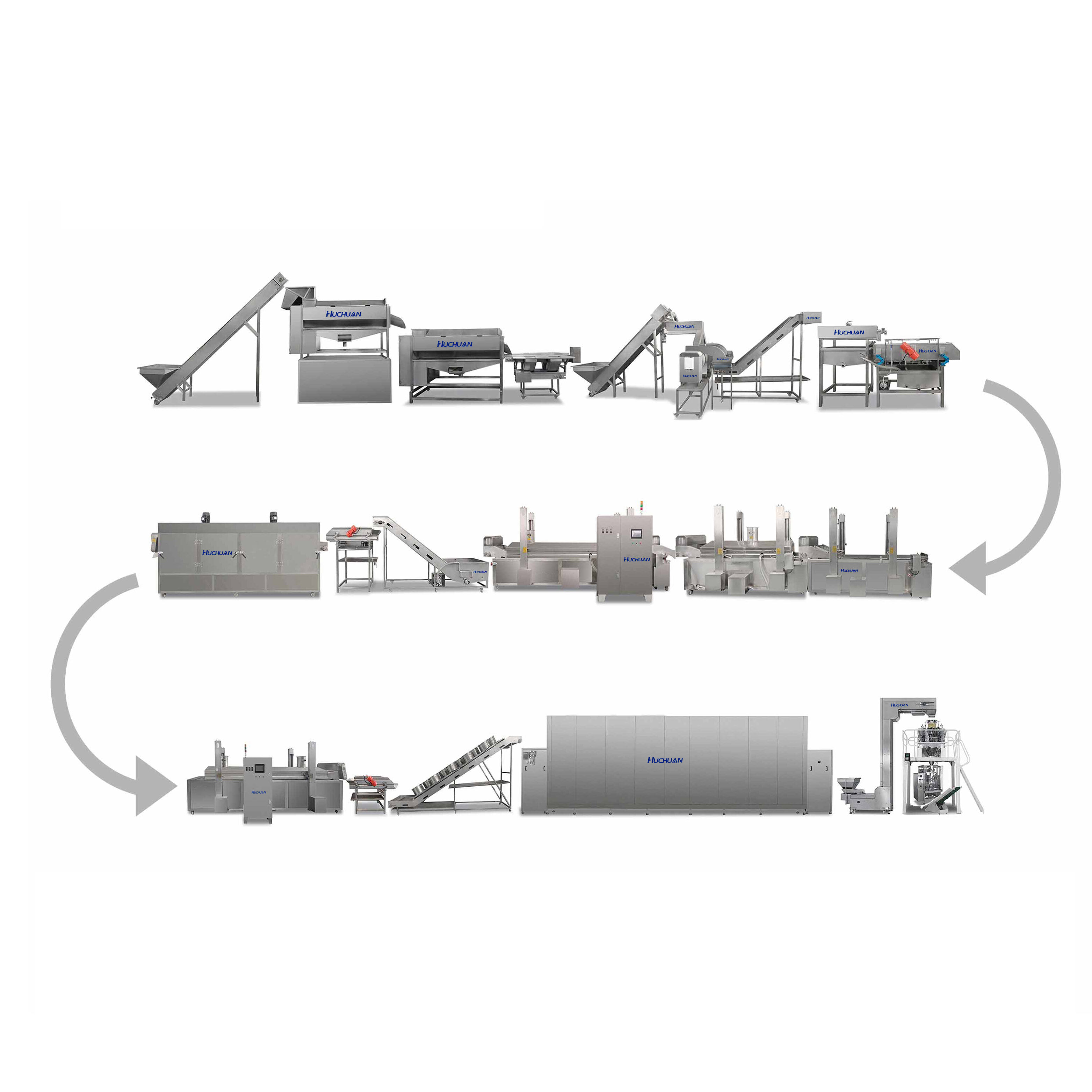

The fresh cut French fries production line is a meticulously designed system that ensures the production of high - quality, freshly cut fries with utmost efficiency. At the start of the line, a high - precision potato sorting mechanism carefully selects potatoes based on size, shape, and quality. This step is crucial as it guarantees that only the best raw materials are used, laying the foundation for superior - quality fries. The potatoes then proceed to the washing and peeling unit, where advanced cleaning technology removes dirt, debris, and the outer skin thoroughly without causing unnecessary waste. The heart of the line is the cutting section, equipped with state - of - the - art cutting blades. These blades can be adjusted to produce French fries of various thicknesses and cuts, from thin shoestring fries to thick steak - cut fries, meeting diverse consumer preferences. After cutting, the fries are conveyed through a precise blanching process. Blanching not only helps to remove surface starch, preventing the fries from sticking together during frying but also preserves their natural color, texture, and nutritional value. Following blanching, the fries are dried to remove excess moisture, which is essential for achieving a perfect, crispy exterior during frying. The frying stage is carefully controlled with advanced temperature - regulation systems. These systems ensure that the fries are cooked evenly, resulting in a golden - brown color, a crispy exterior, and a tender, fluffy interior. After frying, the fresh cut French fries can be optionally cooled and then packaged. The packaging process can be customized, with options for different package sizes, materials, and sealing methods, ensuring the freshness and quality of the fries are maintained during storage and transportation. Overall, this production line combines advanced technology and thoughtful design to deliver fresh cut French fries that meet the highest standards of quality and taste.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy