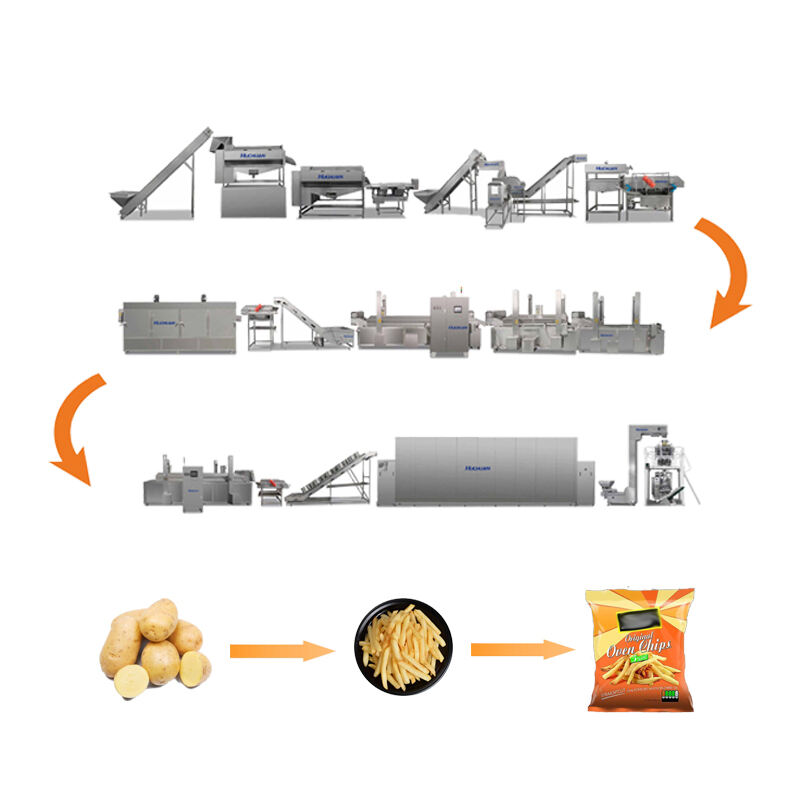

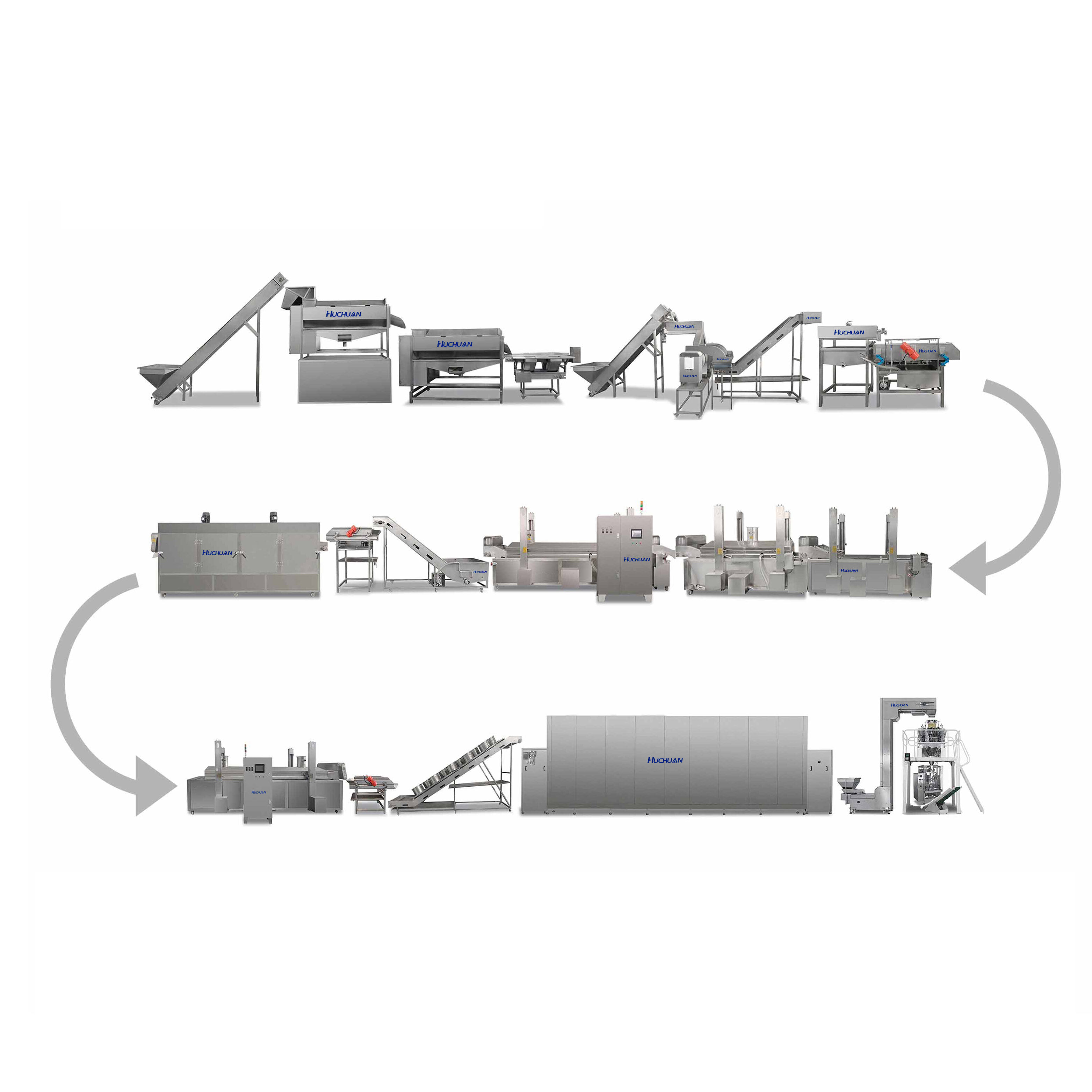

The seasoned french fries production line from KANGBEITE is tailored to meet the rising demand for flavored snacks, merging automation with precision to deliver uniformly seasoned products. Building on the core of a standard fully automatic line, it adds a specialized seasoning application module that ensures every fry is evenly coated. After frying and cooling, fries enter a rotating drum or vibratory conveyor where seasonings—from classic salt and cheese to regional favorites like chili lime or barbecue—are applied. The system uses variable speed controls and adjustable seasoning dispensers to adapt to different particle sizes, preventing clumping and ensuring 100% coverage. Quality sensors integrated into the line monitor seasoning density, alerting operators to deviations and maintaining batch consistency. Quick change hoppers allow for seamless switching between seasoning recipes, enabling manufacturers to produce multiple flavors in a single shift—ideal for targeting diverse markets, such as spicy variants for Asia or smoky profiles for Europe. The seasoning process is enclosed to minimize dust and waste, adhering to strict food safety norms (CE, ISO9001 2015) and ensuring compliance with global health regulations. The line’s design prioritizes hygiene, with easy to clean surfaces and stainless steel components that resist flavor cross contamination. Post seasoning, fries move to packaging, often using MAP technology to preserve flavor integrity. KANGBEITE’s technical team provides on site training for recipe optimization, and lifetime service ensures long term reliability. Exported to over 100 countries, this line empowers brands to expand their product portfolios, capitalizing on consumer preferences for bold, consistent flavors.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy