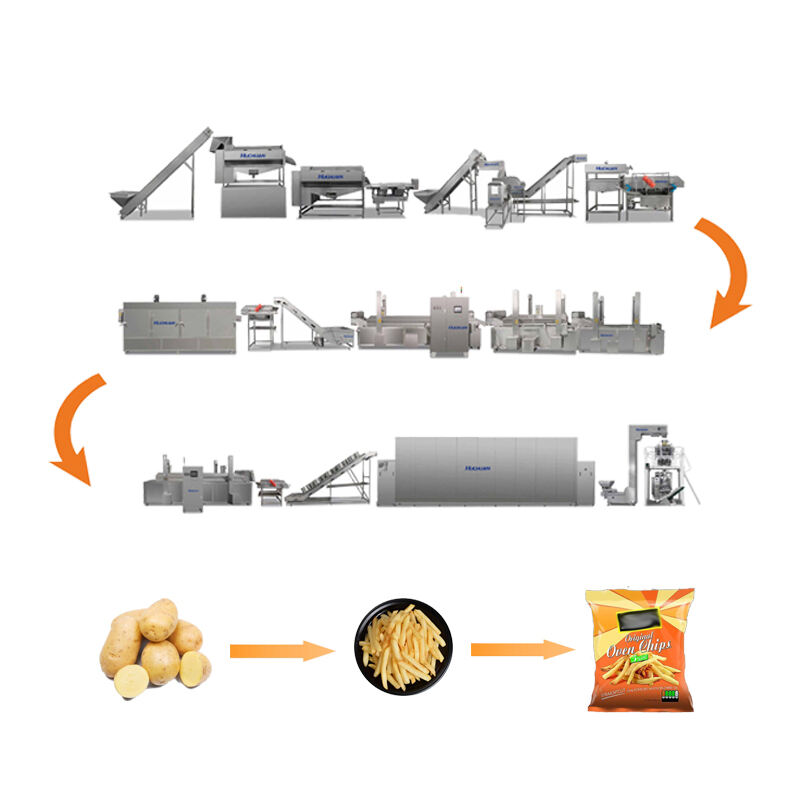

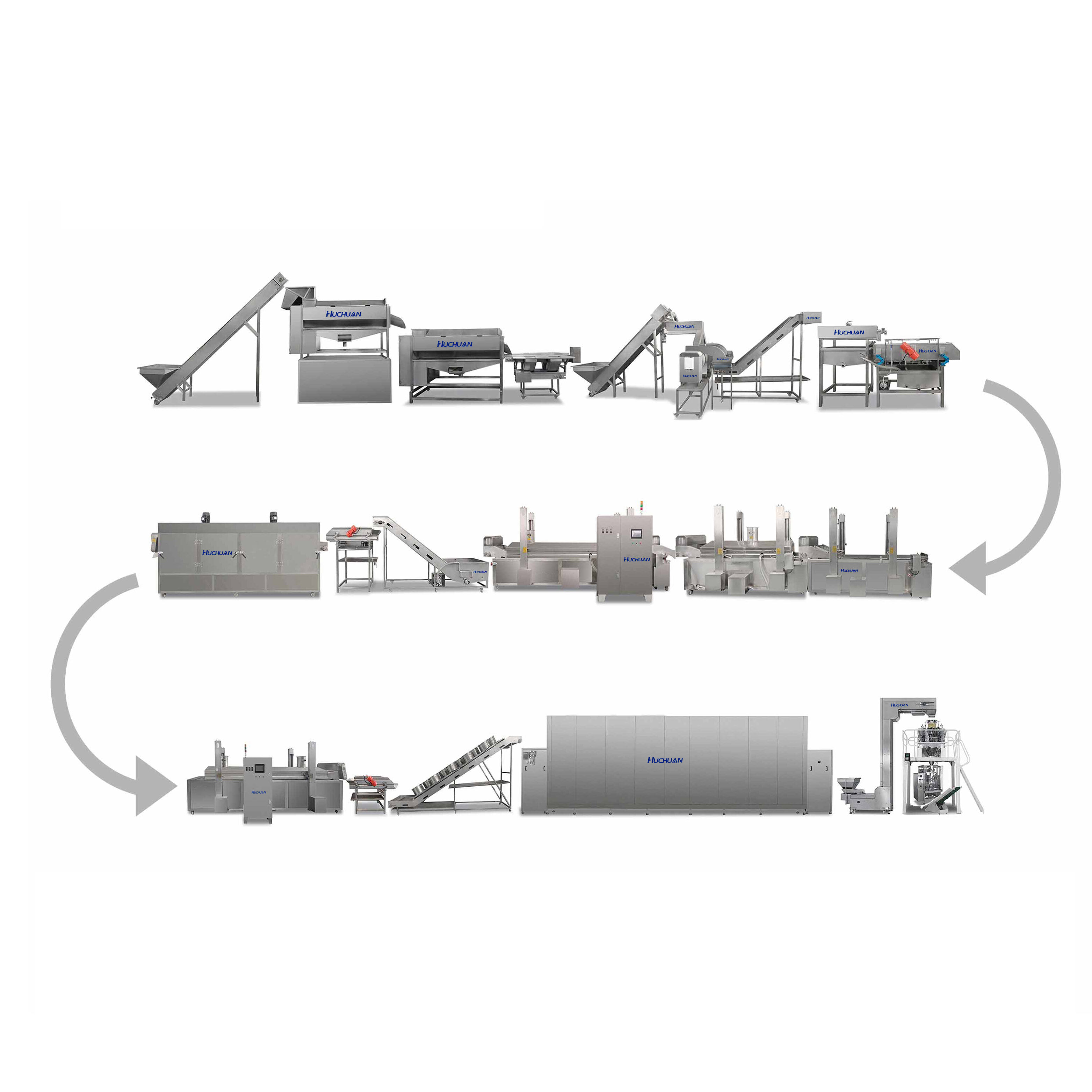

A sweet potato fries production line is a specialized system engineered to process sweet potatoes into frozen or ready-to-eat fries, addressing the crop’s unique characteristics: high starch content (20–25%), delicate flesh prone to enzymatic browning, and thick, fibrous skin that requires gentle removal. The line’s workflow is optimized to preserve sweet potatoes’ nutritional value (rich in beta-carotene/vitamin A, fiber) and texture (crisp exterior, tender interior) while complying with global food safety standards (FDA, EU 1333/2008). It starts with raw material preparation: sweet potatoes are unloaded into a rotary washing tank (equipped with soft brushes and 40–60 psi high-pressure water) to remove dirt and debris without damaging the skin. A size-sorting conveyor (mechanical rollers with adjustable spacing) separates potatoes by diameter (50–150mm) to ensure uniform processing—smaller potatoes are diverted for diced products, while larger ones proceed to fries. Peeling uses a steam peeling system (100–105℃ steam for 30–60 seconds) instead of mechanical peelers: steam softens the skin, which is then removed via rubber rollers, reducing waste to <5% (vs. 8–10% for mechanical peeling) and preserving flesh integrity. Cutting is done via a multi-blade rotary cutter (adjustable blade spacing: 3–10mm) to produce straight or crinkle-cut fries, with a continuous water spray system to remove excess starch—critical for reducing oil absorption during frying and preventing clumping in frozen products. The blanching stage is essential for quality: fries are immersed in 85–95℃ hot water for 1–2 minutes to inactivate polyphenol oxidase (preventing browning) and gelatinize starch (improving crispness after cooking). Post-blanching, fries are cooled in chilled water (0–5℃ for 5–10 minutes) to stop cooking, then dried via high-velocity air blowers (removing surface moisture to avoid oil splattering and ensure even frying/freezing). For frozen fries, the line uses an IQF (Individual Quick Freezing) tunnel (-35℃ to -40℃, 10–15 minutes freezing time) to freeze each fry individually, preventing clumping and preserving texture. For ready-to-eat fries, a continuous fryer (170–190℃ vegetable oil, 2–3 minutes frying time) is used, followed by a centrifugal deoiler (removing excess oil to reduce fat content to 15–20%). Packaging is automated: weigh fillers dispense fries into moisture-proof polyethylene bags (100–200 CPM for frozen products) or modified atmosphere packaging (MAP, 60% CO₂, 40% N₂) for ready-to-eat fries (extending shelf life to 7–10 days). All food-contact parts are 304 stainless steel, with CIP (Clean-in-Place) systems for automated cleaning (hot water + food-grade detergent) to prevent cross-contamination. For processors, this line enables high yield (80–85% from raw sweet potato to finished fries), caters to consumer demand for healthy alternatives to potato fries (lower glycemic index, higher nutrients), and supports global markets—frozen sweet potato fries are popular in North America, Europe, and Asia as a snack, side dish, or fast-food item.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy