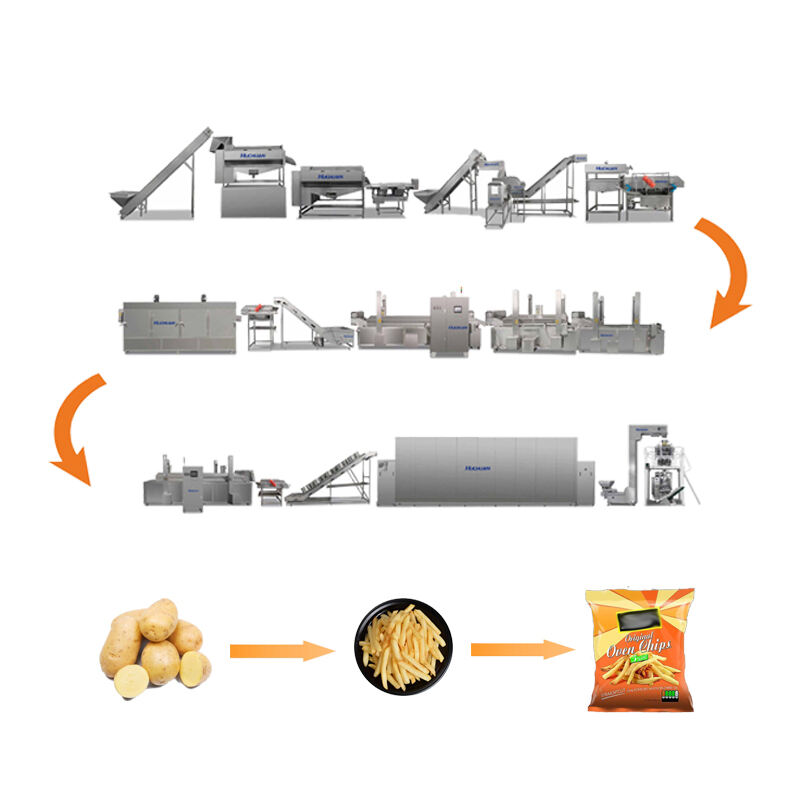

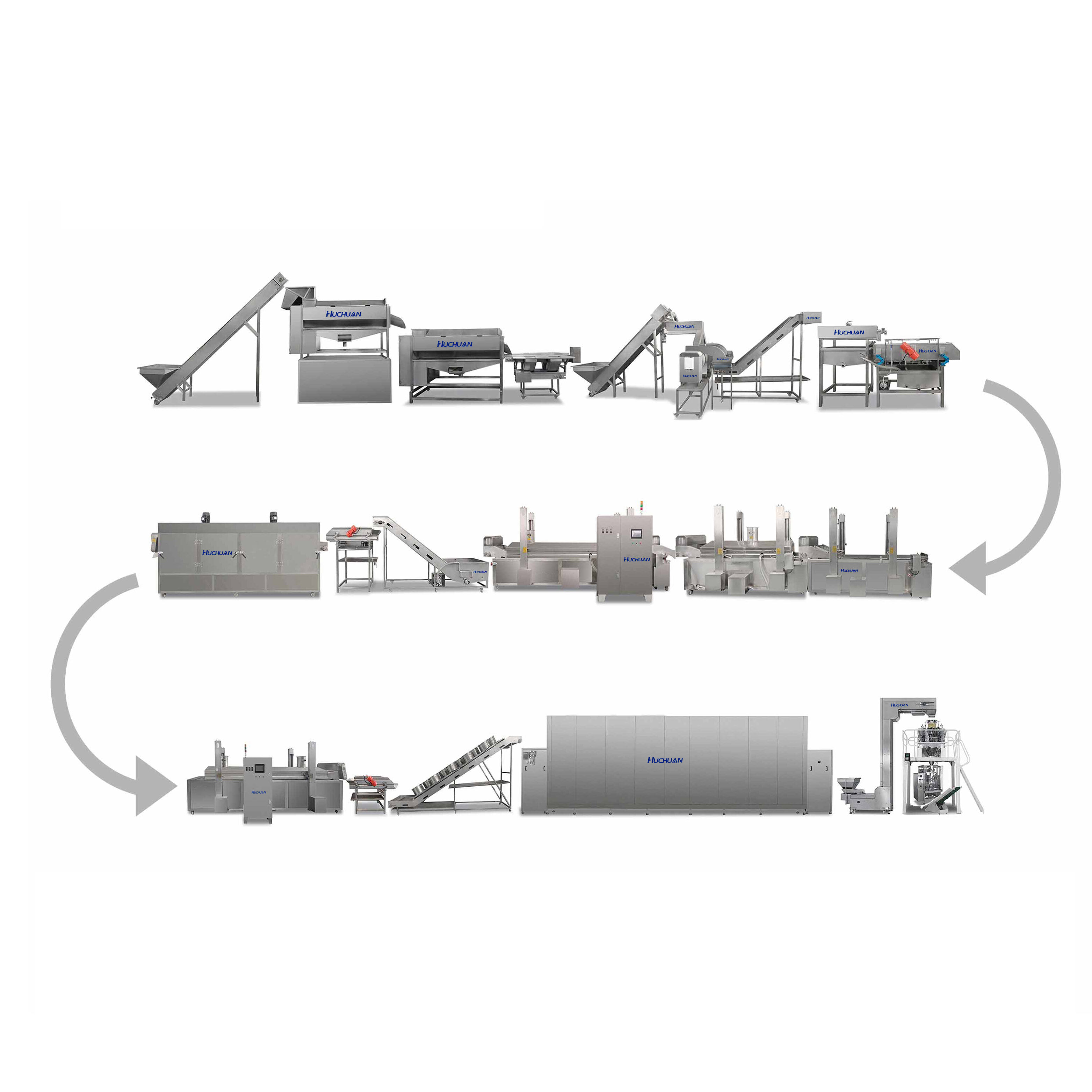

Model For New Automated French Fry Production Line Innovations

Check out the model of our new french fries production line, it has an advanced technology French fries cutting, frying, and packaging system. It is automated in every way possible which makes efficiency, ease, and accuracy unmatched.

Get A Quote