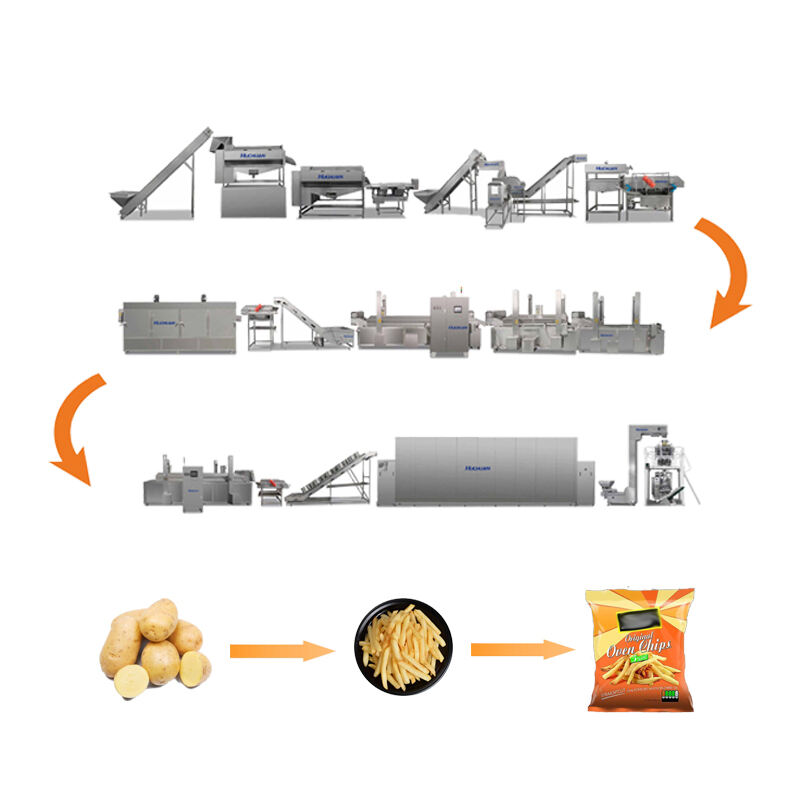

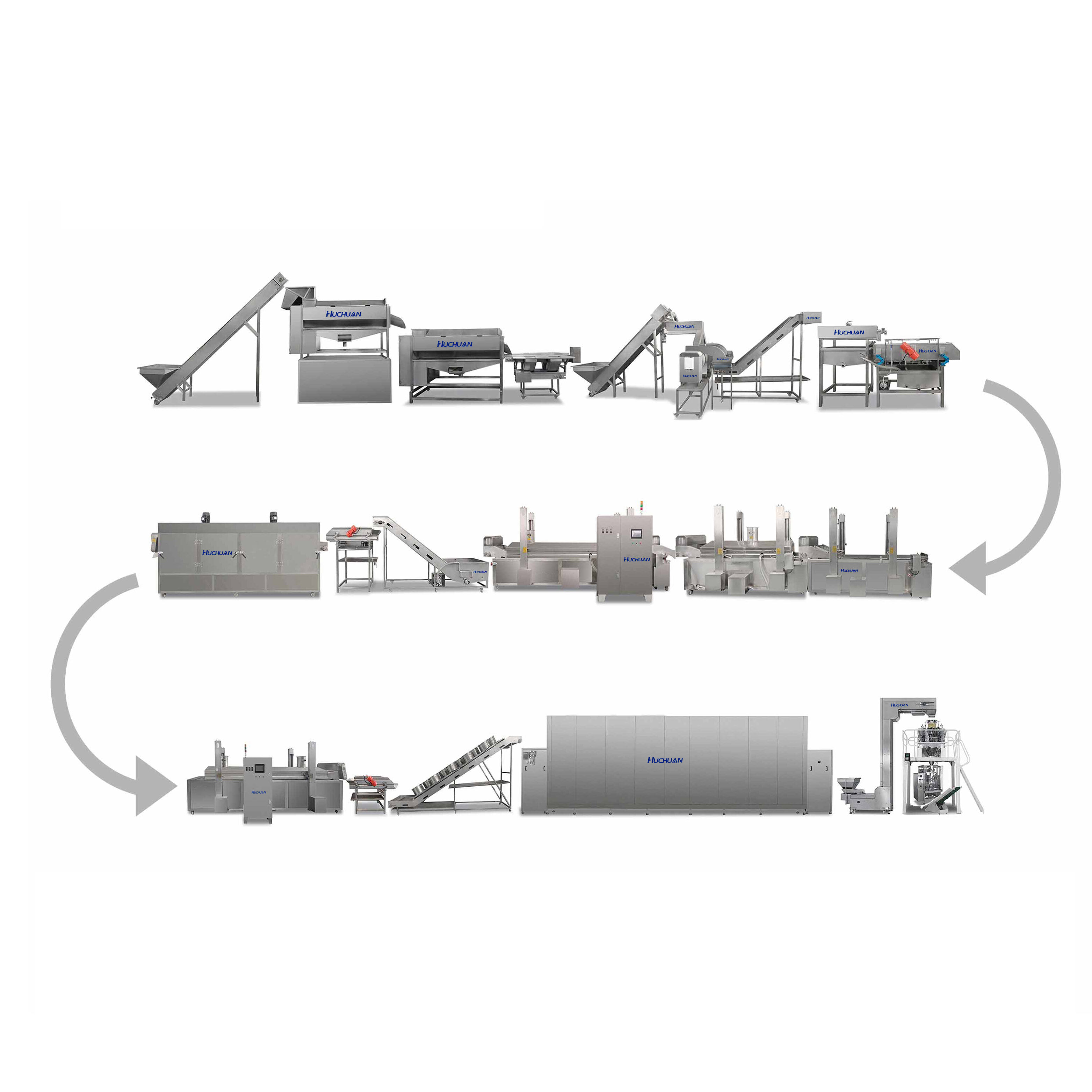

An ISO compliant french fries production line is a specialized system designed to meet the rigorous standards of the International Organization for Standardization (ISO), ensuring consistent quality, food safety, and environmental responsibility throughout the french fry production process. The line aligns with key ISO standards: ISO 9001 (Quality Management Systems) for process consistency, ISO 22000 (Food Safety Management Systems) for hazard control, and ISO 14001 (Environmental Management Systems) for reducing environmental impact—critical for manufacturers seeking to access global markets (e.g., EU, North America, Japan) where ISO compliance is often a mandatory requirement. To meet ISO 9001, the line incorporates documented processes and quality control measures at every stage: raw material inspection (potato variety, size, and moisture content tested via inline sensors to ensure compliance with specifications), standardized operating procedures (SOPs) for roasting, cutting, and blanching (stored in PLC systems to eliminate operator variation), and batch traceability (each batch is assigned a unique code linked to raw material origin, processing parameters, and quality test results). For ISO 22000 compliance, the line implements a Hazard Analysis and Critical Control Points (HACCP) plan with critical control points (CCPs) monitored in real-time: CCP1 (destoning and metal detection to prevent physical hazards), CCP2 (blanching temperature/time to eliminate microbial hazards like Salmonella), and CCP3 (IQF freezing temperature to prevent bacterial growth). Inline sensors and data loggers record CCP data (stored for at least 2 years) for audit purposes, and the line includes sanitization systems (CIP with food-grade detergents, thermal disinfection of equipment) to prevent cross-contamination. ISO 14001 compliance is achieved via energy and resource efficiency: heat recovery systems capture waste heat from fryers and blanchers to preheat water (reducing energy use by 20–30%), water recycling systems (80%+ recovery in starch removal) to minimize wastewater, and waste management systems (potato peel and trimmings are processed into animal feed or biogas). All food-contact materials (316L stainless steel, food-grade films) comply with ISO 10993 (biological evaluation) and regional standards (FDA, EU 10/2011) to prevent chemical migration. The line also includes employee training programs (documented and regularly updated) to ensure staff follow ISO procedures. For manufacturers, ISO compliance offers significant benefits: enhanced market access (meeting import requirements of ISO-certified countries), improved brand reputation (signaling commitment to quality and safety), and reduced risk of product recalls (via robust hazard control). It also supports continuous improvement—ISO’s periodic audits drive refinements to processes (e.g., optimizing blanching time to reduce energy use) and ensure the line adapts to evolving standards and consumer expectations.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy