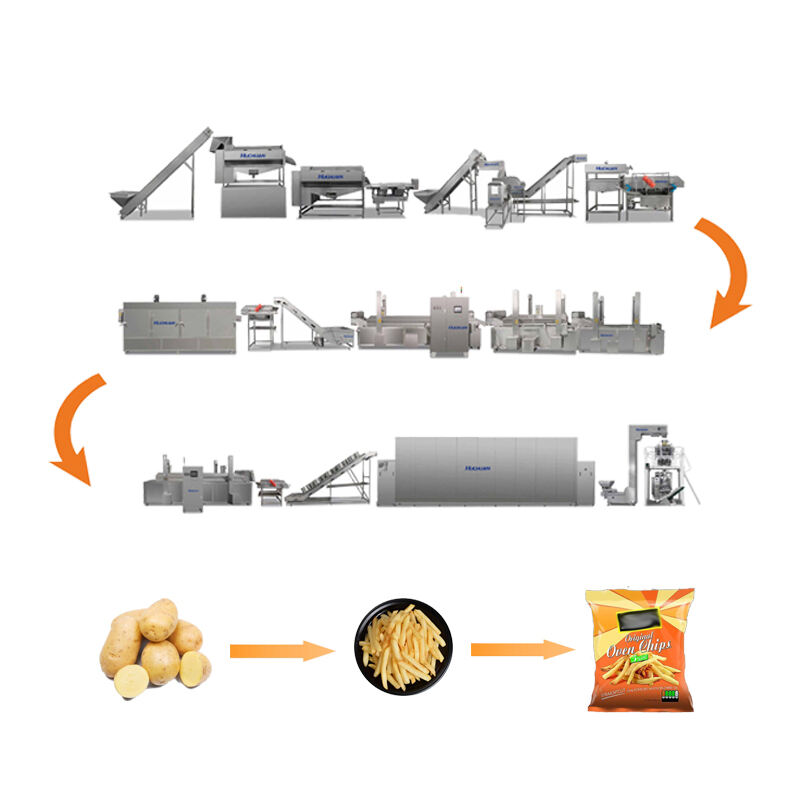

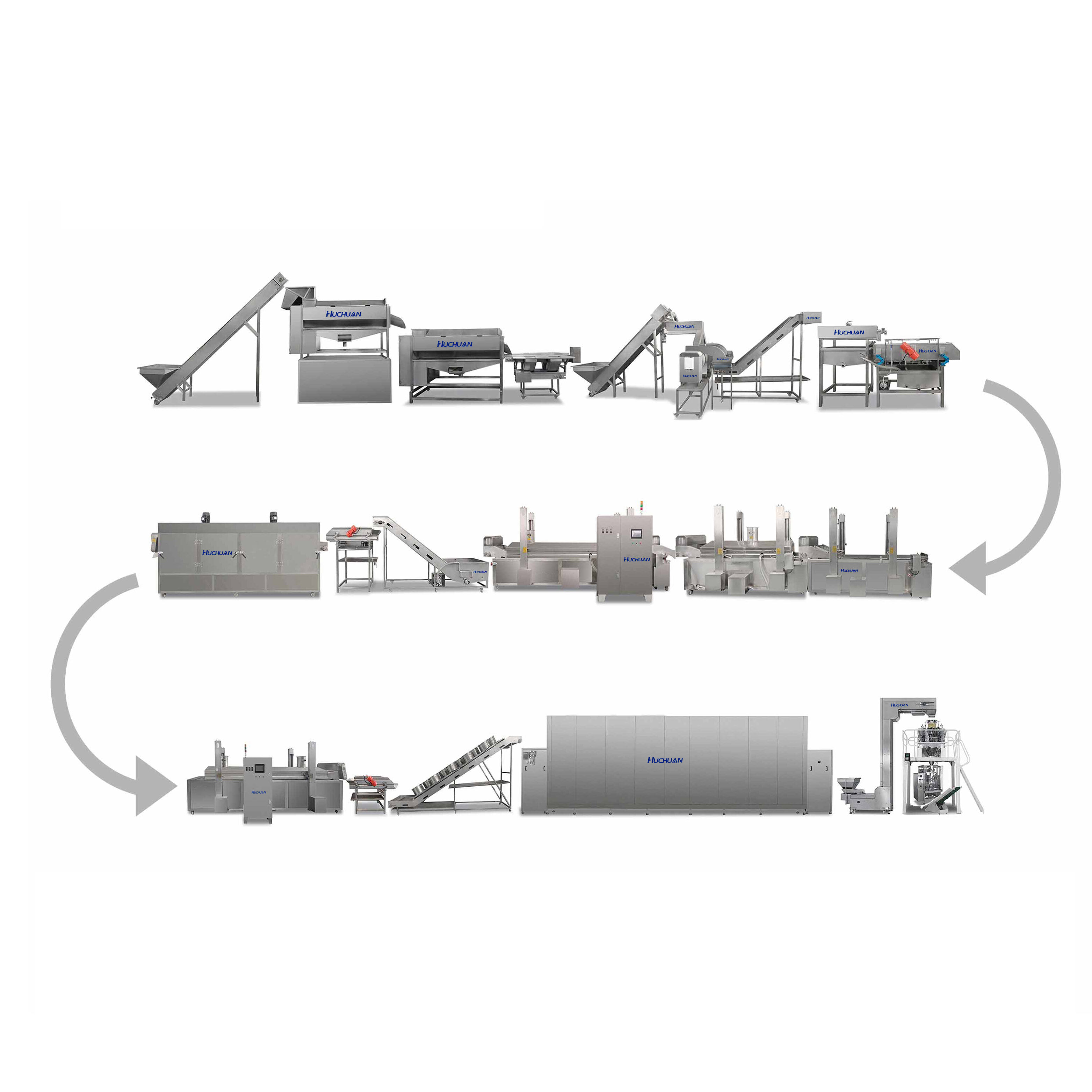

The fries cutting and shaping line is a critical precursor to quality french fries, and KANGBEITE’s iteration sets industry benchmarks for precision. Designed to transform peeled potatoes into uniformly shaped fries, it begins with a gentle infeed system that transports potatoes without bruising, using soft conveyor belts and adjustable guides to accommodate varying tuber sizes. The cutting station features high tensile stainless steel blades, honed to micron level sharpness, which slice potatoes into precise dimensions—from thin 3mm shoestrings to thick 15mm steak cuts. Blade configurations are easily interchangeable, allowing quick shifts between product specs. Beyond cutting, the shaping module refines fries through controlled abrasion, removing jagged edges and creating smooth, uniform surfaces. This step is vital: irregular shapes cause uneven frying, leading to undercooked or overcrisp segments. Sensors in the line detect misshapen pieces, diverting them to a reject chute to maintain quality. The line’s speed synchronizes with downstream processes (blanching, frying), preventing bottlenecks and ensuring a steady flow. Constructed with food grade materials, the line resists starch buildup and is compatible with CIP (Clean in Place) systems for efficient sanitization. Its robust motor and gearbox handle continuous operation, with minimal vibration to protect blade integrity. KANGBEITE’s engineers calibrate each line to customer specific needs, whether for organic potato batches or high volume industrial runs. Backed by CE certification and on site installation support, this line guarantees the consistency that brands rely on to build consumer trust.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy