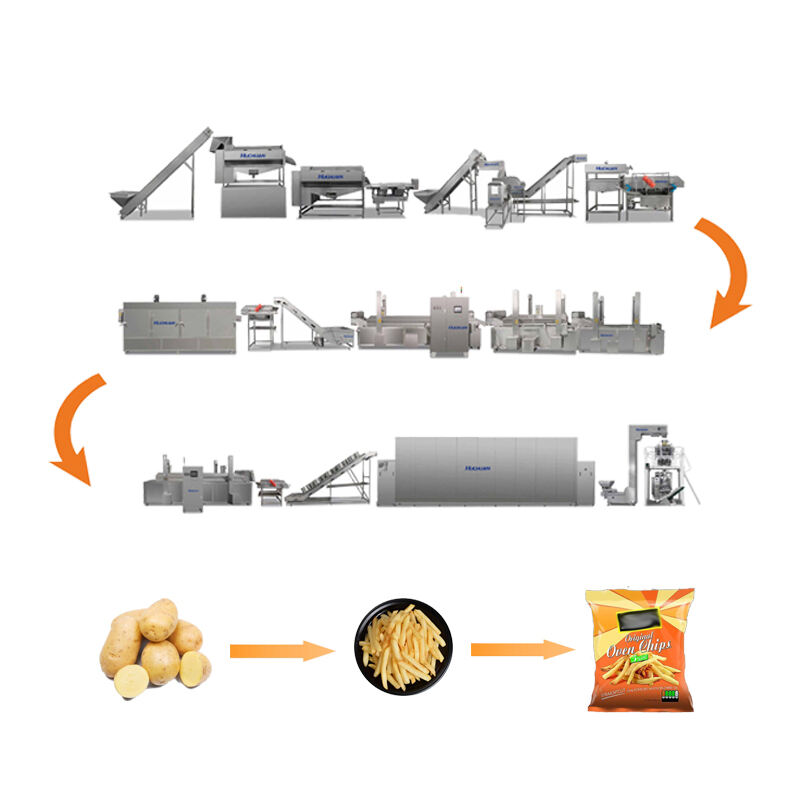

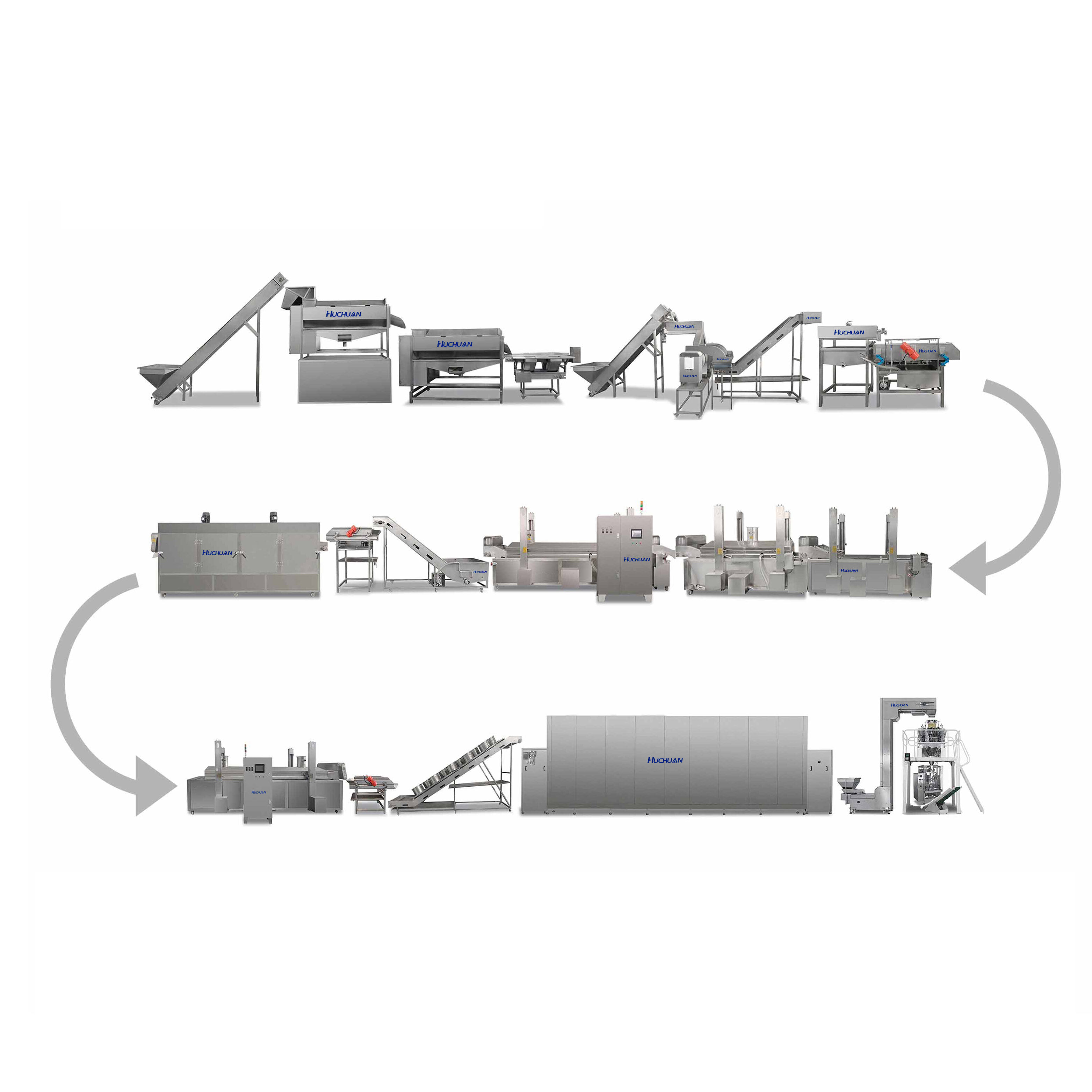

As a leading French fries production line supplier, we pride ourselves on delivering top - notch solutions that meet the diverse needs of the food industry. Our extensive experience and in - depth understanding of the French fries production process allow us to offer production lines that are not only highly functional but also reliable and durable. We understand that each customer has unique requirements, whether it's the scale of production, the types of fries to be produced, or specific budget constraints. That's why our team of experts works closely with clients to design and customize production lines that are tailored to their exact specifications. Our production lines are manufactured using the highest - quality materials and the latest technologies. From the potato sorting and washing equipment to the cutting, frying, and packaging systems, every component is carefully selected and engineered for optimal performance. We also ensure that our production lines comply with international safety and quality standards, such as CE certification and ISO 9001 - 2015. This commitment to quality gives our customers peace of mind, knowing that they are investing in equipment that will deliver consistent, high - quality results. In addition to providing top - of - the - line production lines, we offer comprehensive after - sales support. This includes installation services by our trained technicians, operator training programs to ensure proper use of the equipment, regular maintenance services to keep the lines running smoothly, and a readily available supply of spare parts. With our dedication to quality, customization, and service, we have earned a reputation as a trusted French fries production line supplier, helping food manufacturers around the world enhance their production capabilities and achieve success in the competitive market.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy