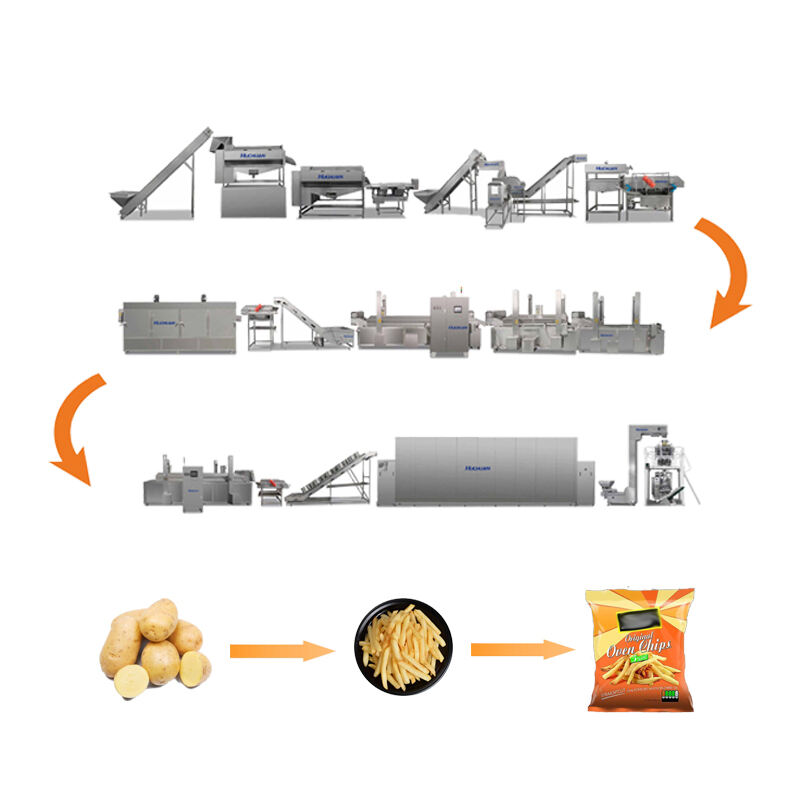

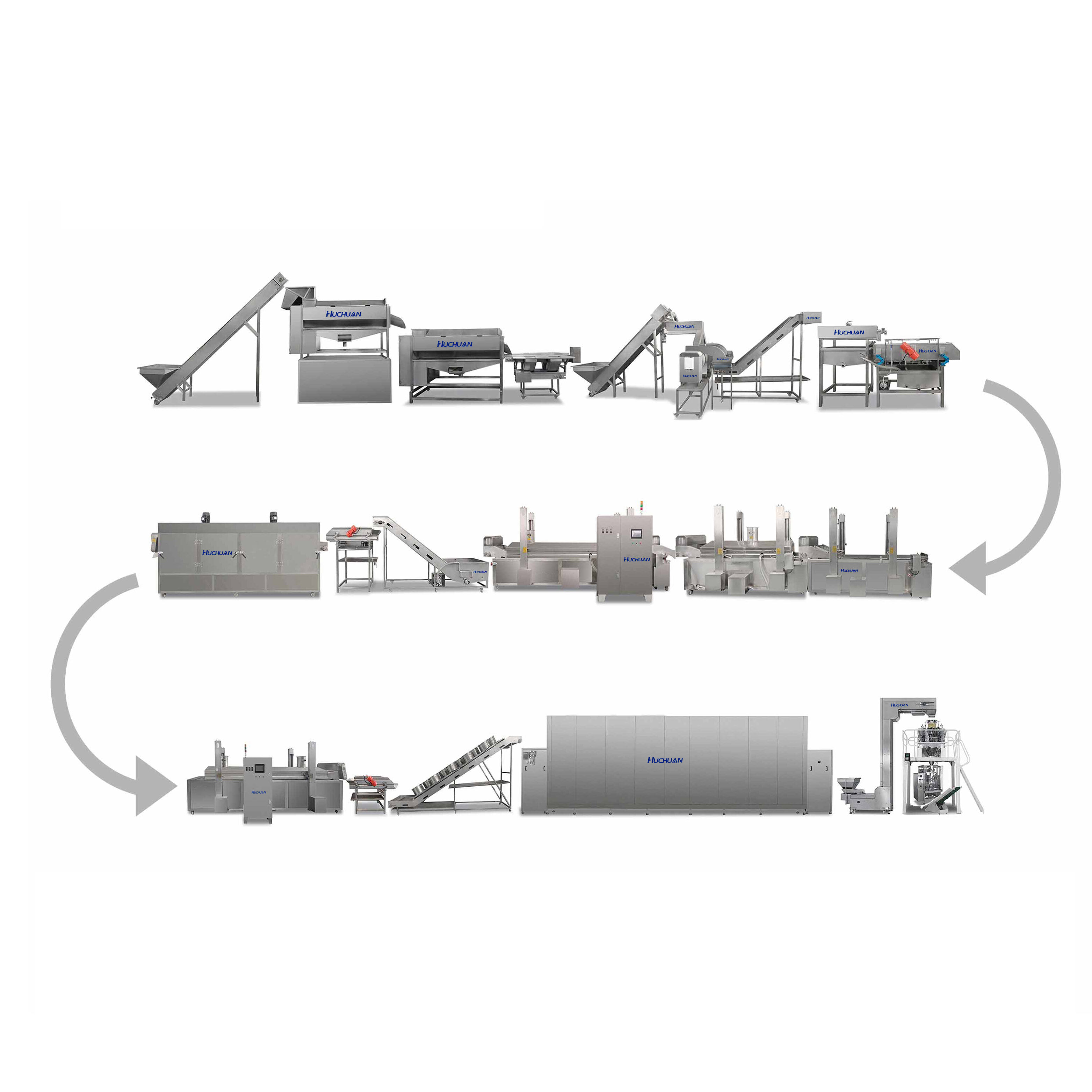

Dây chuyền sản xuất khoai tây chiên tự động hoàn toàn là hệ thống tích hợp thực hiện mọi giai đoạn trong quá trình chế biến khoai tây — từ bước rửa khoai tây nguyên liệu đến thành phẩm khoai tây chiên đông lạnh hoặc đóng gói sẵn sàng tiêu thụ — với sự can thiệp tối thiểu của con người, được thiết kế dành cho các cơ sở chế biến trung bình đến lớn (các nhà cung cấp đồ ăn nhanh, thương hiệu bán lẻ) với sản lượng hàng ngày từ 500–2000 kg. Dây chuyền kết hợp tốc độ, độ đồng đều và an toàn thực phẩm nhằm đáp ứng nhu cầu cao về khoai tây chiên tiêu chuẩn hóa trong khi vẫn giữ được kết cấu (vỏ giòn, ruột mềm mịn) và giảm thiểu hao hụt. Quy trình làm việc của dây chuyền liền mạch và tự động: khoai tây nguyên liệu được đổ vào phễu chứa lớn và được băng tải đưa đến bồn rửa sơ bộ (chổi quay + nước áp suất cao) để loại bỏ đất và lớp vỏ ngoài lỏng lẻo. Hệ thống loại bỏ đá (dựa trên nguyên lý mật độ nước để tách đá khỏi khoai tây) giúp ngăn ngừa hư hại thiết bị và đảm bảo an toàn thực phẩm. Giai đoạn bóc vỏ sử dụng hệ thống bóc vỏ bằng hơi (hơi nước 100–105℃ trong 40–60 giây) hoặc máy bóc vỏ cơ học (con lăn mài mòn) tùy theo giống khoai tây — bóc vỏ bằng hơi nhẹ nhàng hơn (hao hụt <5%) cho sản phẩm khoai chất lượng cao, trong khi bóc vỏ cơ học tiết kiệm chi phí hơn cho sản xuất số lượng lớn. Sau khi bóc vỏ, khoai tây được kiểm tra bằng máy phân loại quang học (loại bỏ những củ bị lỗi như dập, mọc mầm) trước khi cắt. Bộ phận cắt sử dụng dao cắt quay đa lưỡi (khoảng cách lưỡa cắt điều chỉnh: 6–12mm cho khoai tây cắt tiêu chuẩn, 10–15mm cho khoai cắt dày) đi kèm hệ thống phun nước để loại bỏ tinh bột dư thừa — yếu tố quan trọng để tránh dính khoai và đảm bảo chiên đều. Luộc sơ là bước then chốt về chất lượng: khoai tây được ngâm trong nước nóng 80–90℃ trong 2–3 phút để hồ hóa tinh bột (tăng độ giòn) và vô hiệu hóa enzyme (ngăn ngừa chuyển màu). Tiếp theo là băng tải làm lạnh (nước làm lạnh, 0–5℃) dừng quá trình nấu, sau đó là hệ thống loại nước (quạt thổi hoặc máy ly tâm) để loại độ ẩm trên bề mặt. Đối với khoai đông lạnh, dây chuyền sử dụng buồng cấp đông IQF (Individual Quick Freezing) (-35℃ đến -45℃, thời gian đông 8–12 phút) để đông lạnh từng sợi khoai riêng biệt, đảm bảo không bị vón cục. Đối với khoai chiên sẵn, sử dụng máy chiên liên tục (dầu thực vật 175–190℃, thời gian chiên 2,5–3,5 phút), đi kèm hệ thống lọc dầu tự động để loại bỏ cặn thực phẩm và duy trì chất lượng dầu. Thiết bị giảm dầu (ly tâm hoặc thổi khí) giúp giảm hàm lượng chất béo xuống còn 15–20% cho sản phẩm lành mạnh hơn. Đóng gói được thực hiện hoàn toàn tự động: khoai đông lạnh được cân và đóng vào túi chống ẩm (100–150 CPM) hoặc hộp carton bằng máy đóng hộp, trong khi khoai chiên sẵn sử dụng công nghệ đóng gói khí điều chỉnh (MAP, 70% N₂, 30% CO₂) để kéo dài thời hạn sử dụng lên đến 5–7 ngày. Kiểm soát chất lượng được tích hợp xuyên suốt: máy dò kim loại, thiết bị kiểm tra trọng lượng (độ chính xác ±1g) và máy thử độ kín miệng túi đảm bảo tuân thủ các tiêu chuẩn an toàn thực phẩm (FDA, EU 1333/2008). Tất cả các bộ phận tiếp xúc với thực phẩm đều làm bằng thép không gỉ 304, đi kèm hệ thống CIP để tự động vệ sinh nhằm ngăn ngừa nhiễm chéo. Đối với các nhà chế biến, dây chuyền này đảm bảo độ đồng đều về kích thước, kết cấu và hương vị khoai tây chiên (sự biến đổi giữa các mẻ <2%), đáp ứng các thông số kỹ thuật của chuỗi đồ ăn nhanh (ví dụ: chiều dài đồng đều cho máy phân phối khoai), đồng thời có khả năng mở rộng để xử lý nhu cầu tăng cao (ví dụ: mùa lễ hội).

Bản quyền © 2025 thuộc về Công ty TNHH Máy đóng gói thực phẩm Shandong Kangbeite Chính sách bảo mật