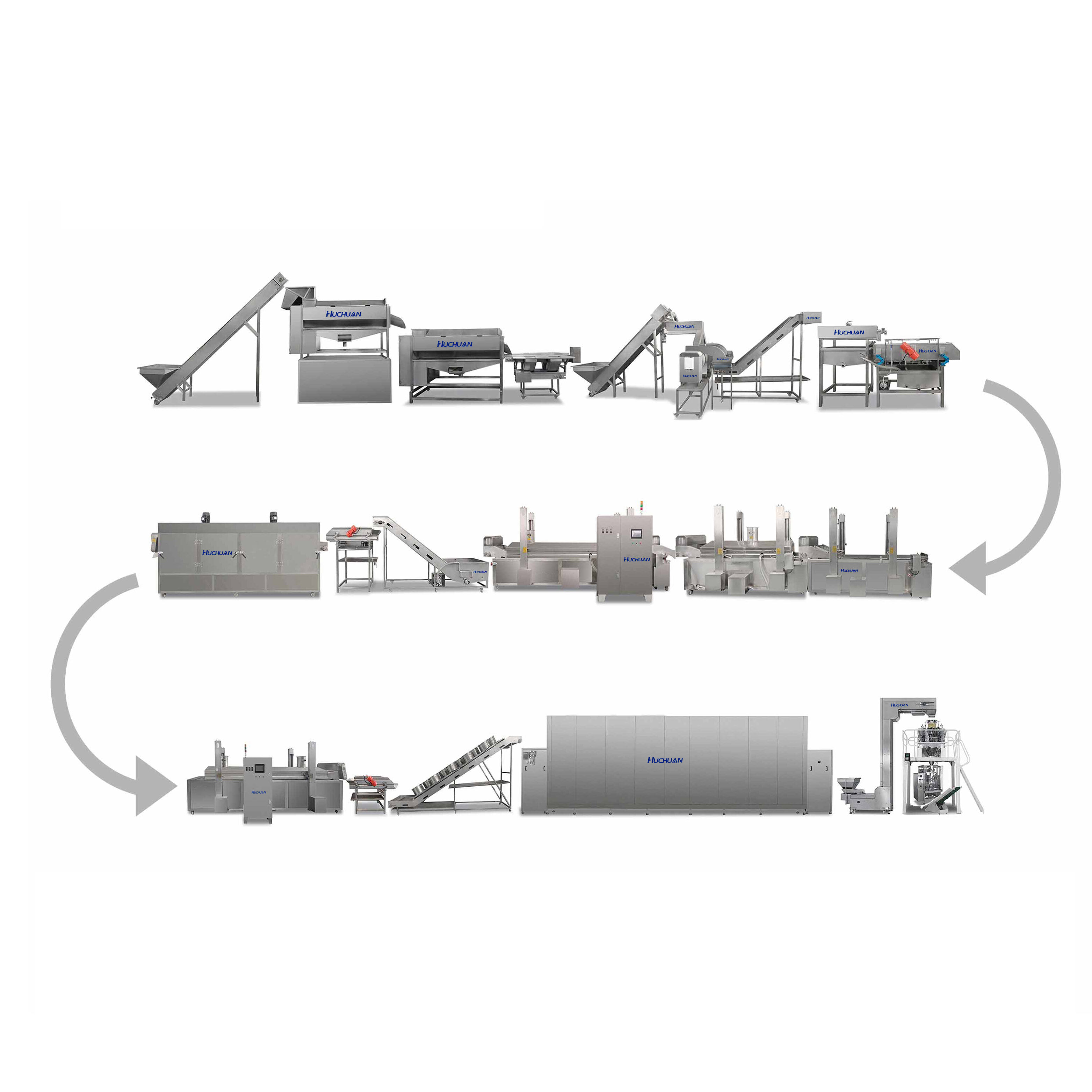

Unha liña de produción de patatas fritas conforme a ISO é un sistema especializado deseñado para satisfacer as rigorosas normas da Organización Internacional de Normalización (ISO), asegurando unha calidade consistente, seguridade alimentaria e responsabilidade ambiental en todo o proceso de produción das patatas fritas. A liña cumpre as principais normas ISO: ISO 9001 (Sistemas de Xestión da Calidade) para a consistencia dos procesos, ISO 22000 (Sistemas de Xestión da Seguridade Alimentaria) para o control de riscos e ISO 14001 (Sistemas de Xestión Ambiental) para reducir o impacto ambiental, esencial para os fabricantes que buscan acceder a mercados globais (por exemplo, UE, América do Norte, Xapón) onde o cumprimento da ISO é frecuentemente un requisito obrigatorio. Para cumprir a ISO 9001, a liña incorpora procesos documentados e medidas de control de calidade en cada etapa: inspección de materias primas (variedade de patata, tamaño e contido de humidade probados mediante sensores en liña para asegurar o seu cumprimento cos requisitos), procedementos operativos normalizados (PON) para o asado, o corte e o escaldado (almacenados en sistemas PLC para eliminar variacións do operador) e trazabilidade por lote (cada lote ten asignado un código único ligado á orixe da materia prima, aos parámetros de procesado e aos resultados dos testes de calidade). Para o cumprimento da ISO 22000, a liña implementa un plan de Análise de Riscos e Puntos de Control Críticos (HACCP) con puntos de control críticos (PCP) monitorizados en tempo real: PCP1 (destonificación e detección de metais para previr riscos físicos), PCP2 (temperatura/tempo de escaldado para eliminar riscos microbianos como a Salmonella) e PCP3 (temperatura de conxelación IQF para previr o crecemento bacteriano). Os sensores e rexistradores en liña recollen datos dos PCP (almacenados durante ao menos 2 anos) para fins de auditoría, e a liña inclúe sistemas de sanitización (CIP con detergentes comestíbeis, desinfección térmica do equipo) para previr a contaminación cruzada. O cumprimento da ISO 14001 lograse mediante a eficiencia enerxética e no uso dos recursos: os sistemas de recuperación de calor capturan o calor residual dos freidores e escaldadores para prequentar auga (reducindo o consumo de enerxía nun 20–30%), os sistemas de reciclaxe de auga (recuperación do 80% ou máis na eliminación do amidón) para minimizar os residuos líquidos e os sistemas de xestión de residuos (as pelas e recortes de patata procesanse en piensos para animais ou biogás). Todos os materiais en contacto co alimento (inoxidable 316L, películas comestíbeis) cumpren a ISO 10993 (avaliación biolóxica) e as normas rexionais (FDA, UE 10/2011) para previr a migración química. A liña tamén inclúe programas de formación para os empregados (documentados e actualizados regularmente) para asegurar que o persoal segue os procedementos ISO. Para os fabricantes, o cumprimento da ISO ofrece importantes beneficios: mellor acceso ao mercado (cumprindo os requisitos de importación dos países certificados ISO), mellorada a reputación da marca (mostrando compromiso coa calidade e a seguridade) e redución do risco de retirada de produtos (mediante un robusto control de riscos). Tamén apoia a mellora continua: as auditorías periódicas da ISO impulsan melloras nos procesos (por exemplo, optimizar o tempo de escaldado para reducir o consumo de enerxía) e aseguran que a liña se adapte a normas en evolución e ás expectativas dos consumidores.

Dereitos de autor © 2025 por Shandong Kangbeite Food Packaging Machine Co., Ltd. Política de privacidade