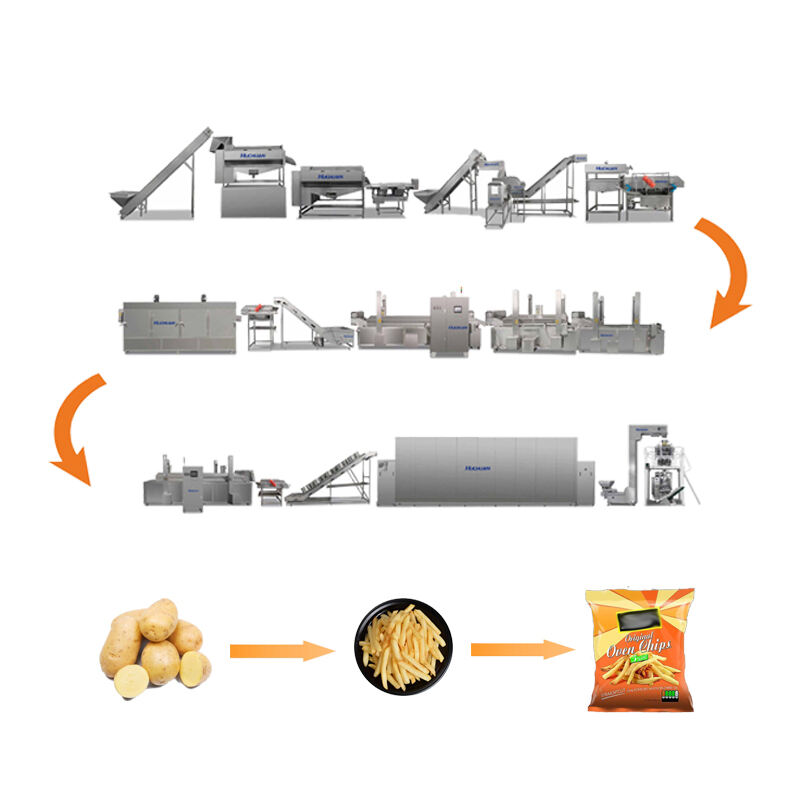

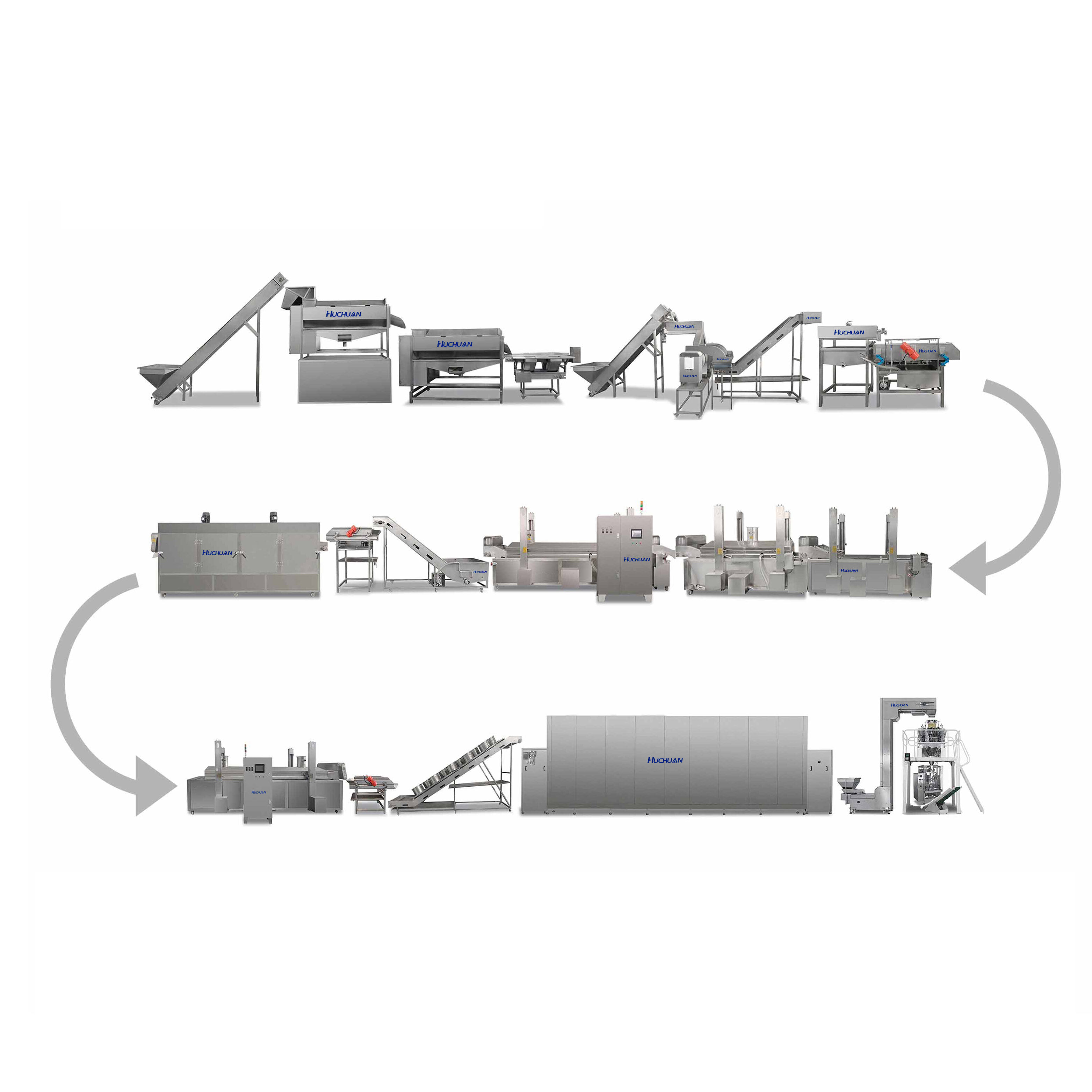

No sector alimentario, onde a produción a gran escala é frecuentemente necesaria para satisfacer as demandas do mercado, unha liña de produción de patatas fritas de alta capacidade é un activo inestimable. Este tipo de liña de produción está deseñada para manexar volumes substanciais de patatas, converténdolas en patatas fritas de alta calidade dun xeito rápido e eficiente. A liña comeza cun robusto sistema de recepción e selección de patatas que pode manexar grandes cantidades de patatas á vez. Sensores avanzados e mecanismos de selección mecánica separan rapidamente as patatas en función do tamaño, calidade e calquera imperfección, asegurando que só se procesen as patatas adecuadas. A unidade de lavado e pelado está deseñada con sistemas de auga de alto fluxo e tecnoloxías de pelado eficientes para limpar e preparar as patatas para o corte no menor tempo posible. A sección de corte presenta múltiples lamas de corte de alta velocidade dispostas nunha configuración que maximiza a producción. Estas lamas poden producir un alto volume de patatas fritas en varias estilos ao mesmo tempo. Despois do corte, as patatas fritas pasan por un proceso continuo de blanqueamento e secado, que está optimizado para unha produción de alta capacidade. O sistema de freir é un dos componentes máis críticos da liña de alta capacidade. Consiste en freidoras a gran escala con elementos calefativos potentes e sistemas de circulación de óleo eficientes. Estas freidoras poden cocer un gran número de patatas fritas uniformemente e rapidamente, mantendo unha calidade consistente incluso a altas taxas de produción. Despois do freído, as patatas fritas son rapidamente arreficidas e despois transferidas á área de embalaxe. O equipo de embalaxe nunha liña de alta capacidade é capaz de encher e sellar un gran número de embalaxes por minuto, coas opcións para diferentes tamaños e tipos de embalaxe. Ao longo de todo o proceso, a liña está equipada con sistemas avanzados de monitorización e control. Estes sistemas monitorizan continuamente parámetros clave como a temperatura, a velocidade e o volume de produción, asegurando que a liña de produción de patatas fritas de alta capacidade opere suavemente, eficientemente e con un mínimo de tempos de inactividade, facendo que sexa a elección ideal para fabricantes alimentarios a gran escala.

Dereitos de autor © 2025 por Shandong Kangbeite Food Packaging Machine Co., Ltd. Política de privacidade