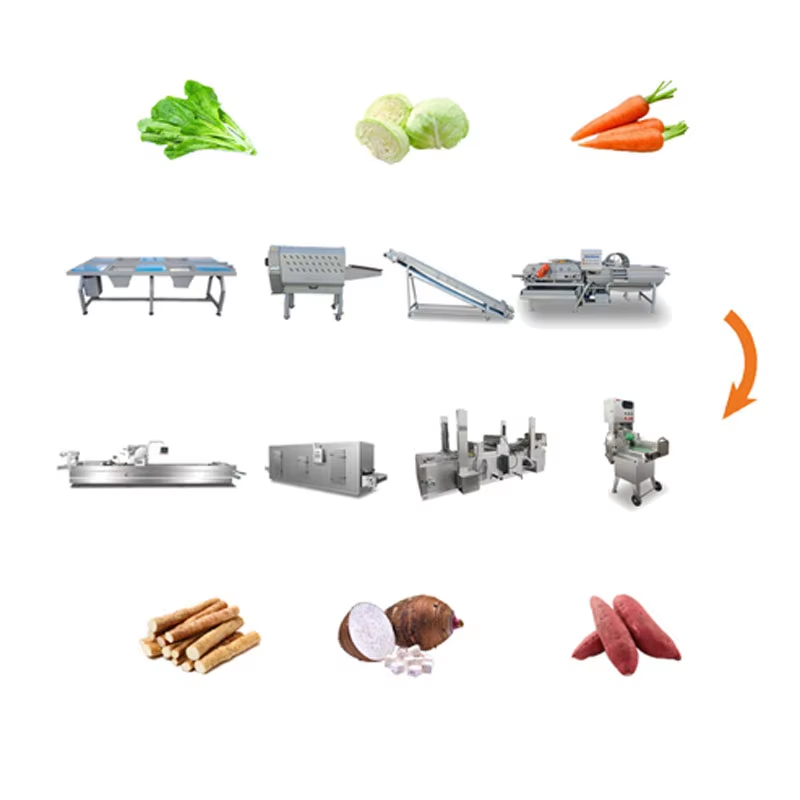

সবজি জন্য হিমায়ন সরঞ্জাম সবজি এর অনন্য শারীরিক এবং জৈব রাসায়নিক বৈশিষ্ট্য মোকাবেলা করার জন্য ইঞ্জিনিয়ারিং হিমায়ন প্রযুক্তির একটি বিশেষ বিভাগ, হিমায়ন এবং সঞ্চয় করার সময় তাদের টেক্সচার, রঙ, পুষ্টি এবং নিরাপত্তা সর্বোত্তম সংরক্ষণ নিশ্চিত। সবজি যেমন ব্রোকলি, গাজর, আলু, মটরশুটি এবং পাতলা সবজিতে উচ্চ মাত্রার জল, এনজাইম (যেমন, পারক্সাইডাসেস, পলিফেনল অক্সাইডাসেস) এবং ফাইবার থাকে, যা সেল ক্ষতি, এনজাইমেটিক ব্রাউনিং এই সরঞ্জামগুলি দ্রুত, অভিন্ন হিমায়নের মাধ্যমে এই সমস্যাগুলি প্রশমিত করার জন্য ডিজাইন করা হয়েছে, আইএসও 22000, এইচএসিসিপি এবং আঞ্চলিক বিধিবিধানের মতো শিল্পের মানগুলির সাথে সামঞ্জস্যপূর্ণ (যেমন, ইইউ ইসি 853/2004, মার্কিন এফডিএ 21 সিএফআর) । সবজি জন্য সবচেয়ে সাধারণ ধরনের হিমায়ন সরঞ্জাম IQF (ব্যক্তিগত দ্রুত হিমায়ন) টানেল, স্পাইরাল হিমায়ন, এবং ব্যাচ হিমায়ন অন্তর্ভুক্ত। আইকিউএফ টানেলগুলি ছোট থেকে মাঝারি আকারের সবজি (মটরশুটি, ডাইসযুক্ত গাজর, ব্রকলি ফুল) এর জন্য আদর্শ, প্রতিটি টুকরো পৃথকভাবে হিমায়িত করতে উচ্চ-গতির ঠান্ডা বাতাস (-35 °C থেকে -45 °C) ব্যবহার করে, এক তাদের উল্লম্ব স্পাইরাল কনভেয়র ডিজাইনের সাথে স্পাইরাল ফ্রিজগুলি মেঝেতে স্থান সাশ্রয় করে এবং উচ্চ ক্ষমতা পরিচালনা করে (1,0005,000 কেজি / ঘন্টা), যা তাদের ফরাসি ফ্রাই বা স্লাইসযুক্ত আলুর মতো বড় আকারের শাকসব্জির উত্পাদনের জন্য এদিকে, ছোট লট বা অনিয়মিত আকারের সবজি (যেমন, পুরো মরিচ, ফুলকপি মাথা) জন্য লট ফ্রিজ ব্যবহার করা হয়, যা নমনীয় প্রক্রিয়াকরণের অনুমতি দেয়। অনেক সিস্টেমে সংহত একটি গুরুত্বপূর্ণ প্রাক-ফ্রিজিং ধাপ হ'ল ব্লাঞ্চিংউষ্ণ জল বা বাষ্প ব্যবহার করে এনজাইমগুলি নিষ্ক্রিয় করতে এবং মাইক্রোবিক লোড হ্রাস করতেএকটি মসৃণ কাজের প্রবাহের জন্য অন্তর্নির্মিত ব্লাঞ্চিং মডিউল সহ উদ্ভিদ হিমায়নের জন্য বিশেষ নকশা বৈশিষ্ট্যগুলির মধ্যে সামঞ্জস্যযোগ্য বায়ু প্রবাহের হার (বৈচিত্র্যময় উদ্ভিদ ঘনত্বের জন্য), খাদ্য-গ্রেড স্টেইনলেস স্টিল (304 বা 316) যোগাযোগের পৃষ্ঠতল (উদ্ভিদ অ্যাসিড থেকে ক্ষয় প্রতিরোধী এবং ঘন ঘ বিশেষ করে সূক্ষ্ম পাতাযুক্ত সবুজ শাকসব্জি (স্পানাচ, কল) এর জন্য, কিছু সরঞ্জাম তরল নাইট্রোজেন (১৯৬° সেলসিয়াস) দিয়ে ক্রিওজেনিক ফ্রিজিং ব্যবহার করে সেকেন্ডের মধ্যে তাদের ফ্রিজ করে, আর্দ্রতা হ্রাসকে কমিয়ে দেয় এবং শক্তির দক্ষতা একটি মূল ফোকাস, তাপ পুনরুদ্ধার সিস্টেমের মতো বৈশিষ্ট্যগুলির সাথে (প্রবেশকারী শাকসব্জিগুলি প্রাক-শীতল করার জন্য বর্জ্য ঠান্ডা বায়ু ধরে রাখা), পরিবর্তনশীল গতির সংক্ষেপক এবং পরিচালনা ব্যয় হ্রাস করতে LED আলো। এছাড়াও, আধুনিক সরঞ্জামগুলির মধ্যে স্পর্শকাতর স্ক্রিন ইন্টারফেস সহ পিএলসি-ভিত্তিক নিয়ন্ত্রণ ব্যবস্থা অন্তর্ভুক্ত রয়েছে, যা অপারেটরদের হিমায়নের সময়, তাপমাত্রা এবং কনভেয়র গতির মতো পরামিতিগুলি পর্যবেক্ষণ এবং সামঞ্জস্য করতে সক্ষম করে যা ব্যাচ জুড়ে ধারাবাহ মসৃণ, ফাটল মুক্ত পৃষ্ঠ, অপসারণযোগ্য উপাদান এবং স্বয়ংক্রিয় সিআইপি (পরিচ্ছন্ন-অবস্থানে) সিস্টেমের মাধ্যমে স্যানিটাইজেশন সহজ করা হয়, যা ক্রস-দূষণের ঝুঁকি হ্রাস করে। ক্ষমতার বিকল্পগুলি স্থানীয় প্রক্রিয়াকরণকারীদের জন্য ছোট আকারের ইউনিট (50200 কেজি/ঘন্টা) থেকে বহুজাতিক খাদ্য সংস্থাগুলির জন্য শিল্প-স্কেল সিস্টেম (5,000 কেজি/ঘন্টা) পর্যন্ত বিস্তৃত। বিশ্বব্যাপী সার্টিফিকেশন (সিই, এফডিএ, জেএএস) মেনে চলা নিশ্চিত করে যে হিমায়িত সবজি আন্তর্জাতিক বাজারে রপ্তানি করা যেতে পারে। সংক্ষেপে, সবজি জমাট বাঁধার সরঞ্জামগুলি খাদ্য শিল্পের জন্য একটি গুরুত্বপূর্ণ সরঞ্জাম, যা বিশ্বব্যাপী ভোক্তা এবং নিয়ন্ত্রকদের কঠোর নিরাপত্তা এবং মানের চাহিদা পূরণ করে উচ্চমানের, পুষ্টিকর সবজি সারা বছর ধরে উপলব্ধ করতে সক্ষম করে।

কপিরাইট © ২০২৫ শান্ডং ক্যানবেইটে ফুড প্যাকেজিং মেশিন কো., লিমিটেড. গোপনীয়তা নীতি