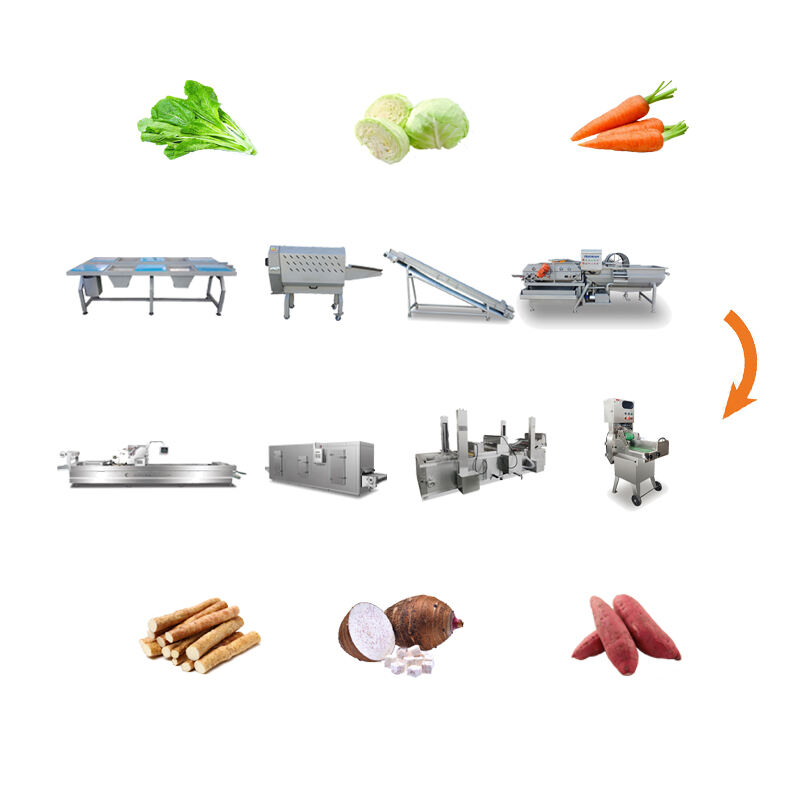

Индустриални промивачи на зеленчуци са специализирани машини, предназначени за премахване на мръсотия, пестициди, бактерии и други замърсители от големи обеми зеленчуци, като се осигурява безопасност и качество на храната, като се поддържа ефективност. Тези промивачи използват комбинация от механично действие, налягане на водата и понякога химични обработки (като хлор или озон), за да постигнат основно почистване, адаптирайки се към уникалните характеристики на различните зеленчуци – от нежни листни зеленчуци до здрави кореноплодни култури. Процесът на промиване обикновено започва с етап на предварително изплакване, при който зеленчукът се напръсква с вода под високо налягане, за да се отстранят замърсители от повърхността. След това те преминават към основна камера за промиване, която може да използва въртящи четки, мехурчета или ултразвукови вълни: четките са ефективни за кореноплодни зеленчуци като моркови и картофи, премахвайки пръст и външни дефекти; системи с мехурчета използват компресиран въздух, за да създадат турбуленция, нежно почиствайки сочни зеленчуци като лют салат или шпинат; ултразвуковите промивачи генерират високочестотни звукови вълни, които премахват замърсители от труднодостъпни места, идеални за зеленчуци с неправилна форма. Интегрирани са системи за рециклиране на вода, за да се минимизира консумацията, филтрирайки и използвайки повторно водата, докато се отстраняват остатъци, намалявайки екологичния ефект и оперативните разходи. След промиването зеленчукът минава през етап на сушене, използвайки вентилатори или центробежна сила, за да се отстрани излишната влага, което предотвратява микробен растеж и ги подготвя за обработка или опаковане. Индустриални промивачи на зеленчуци са произведени от неръждаема стомана за хранителна индустрия, с лесно достъпни компоненти за почистване и поддръжка, съответствайки на хигиенни стандарти като FDA и EU 10/2011. Те се интегрират безпроблемно с друго оборудване за обработка, като ощипвачи, рязачки или сортиращи машини, формирайки непрекъснат производствен процес. С капацитети от 500 кг до 10 тона в час, тези промивачи са от съществено значение за производители в голям мащаб, осигурявайки, че зеленчукът отговаря на глобални стандарти за безопасност и намалява риска от хранителни заболявания, което е критично за поддържането на потребителско доверие и достъп до пазара.

Права на автор © 2025 от firma Shandong Kangbeite Food Packaging Machine Co., Ltd. Политика за поверителност