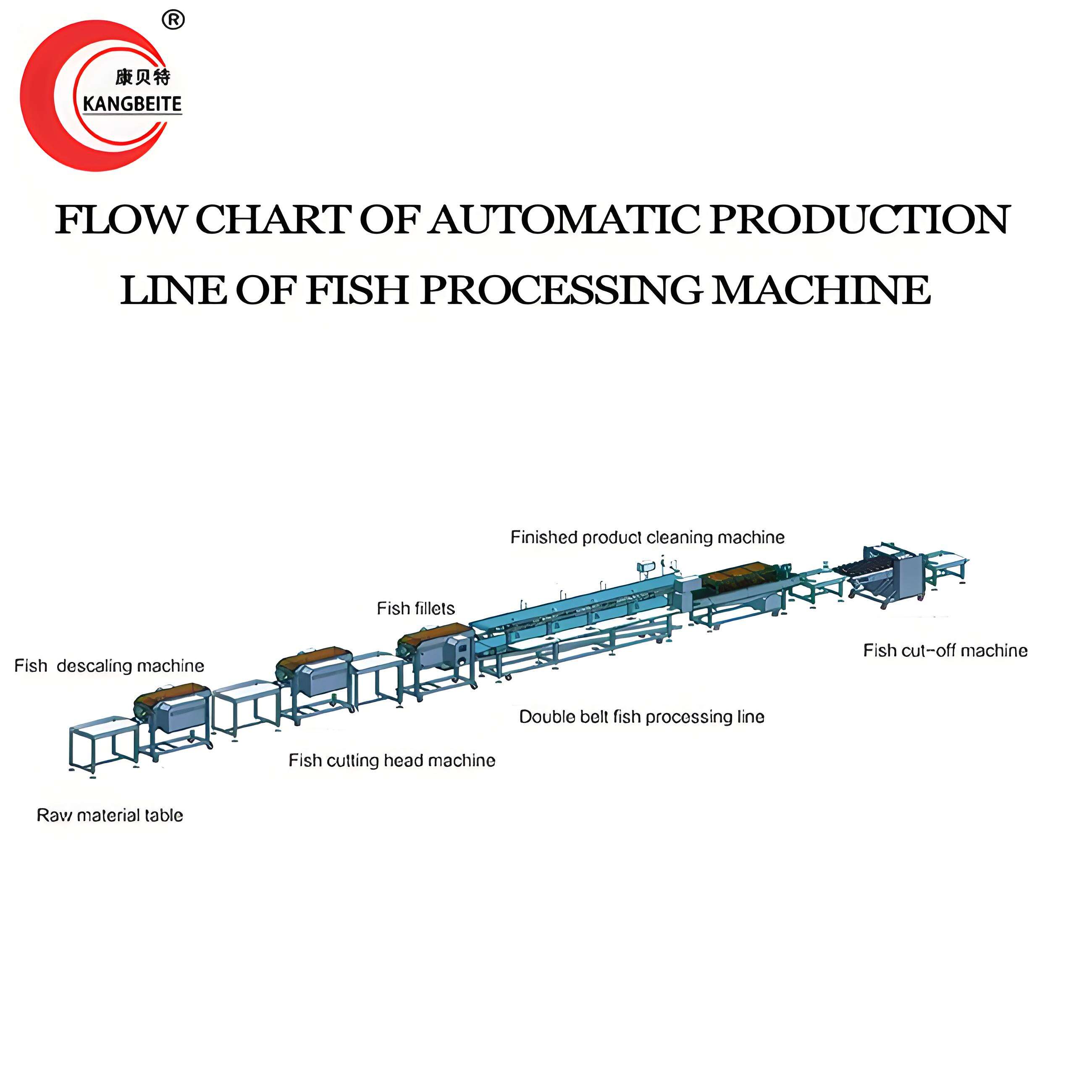

Автоматичната линия за обработка на риба на KANGBEITE е върховно решение, projektова да преобразува индустрията по обработка на морски продукти чрез максимизиране на ефективността и минимизиране на ръчния труд. Тази напълно автоматизирана линия охвъща целият процес на обработката на риба, от момента, когато суровата риба влиза в установката, до производството на готовите продукти. Начално рибата се подава на конвеерна система, която я пренася през серия от автоматизирани стации. Първата стация обикновено включва сортиране, където продължителни оптични машини за сортиране, оснащени с високоразрешителни камери и интелигентни алгоритми, анализират размера, формата, цвета и качеството на рибата. Тези машини могат бързо да разделят рибата в различни категории, гарантирайки, че всяка партия се обработва според нейните специфични изисквания. След това се провежда процесът на чистене на чешуята, използвайки автоматизирани машини за чистене на чешуя. Те използват комбинация от механични и водни струйни технологии; високоскоростни вращащи се щети или лези, заедно с точно контролирани водни струи, работят в хармония, за да премахнат чешуята от всички части на рибата, включително труднодостигаемите области. След чистенето на чешуята, рибата се движи към стациите за изсмукване на втрешности и промиване. Автоматичните машини за изсмукване на втрешности, оснащени с остри, регулируеми лези, правят точни разцепления, за да премахнат втрешните органи, докато интегрирани системи за водна промива彻底 очистват абдоминалната каверна. Отпадъците, произведени по време на тези процеси, се събират и премахват автоматично от интегрирана система за управление на отпадъци. На филетовата стадия линията включва модерни машини за филетуване. Те са оснащени с продължителни сензори и роботизирани ръце, които може точно да засичат костената структура на рибата и да правят точни разцепления, за да отделят филетата. Някои модели дори използват технология на компютърно зрение, за да се адаптират към различните форми и размери на рибата, гарантирайки висококачествени филета с минимален отпадък. След филетуването, филетата се чистят автоматично, промиват се и сортират според размера. Последната стадия на автоматичната линия за обработка на риба е упаковката. В зависимост от типа продукт, линията може да бъде интегрирана с различни машини за упаковка, като машини за вакуумна упаковка, машини за пломбиране на тарелки или консервни линии. Тези машини за упаковка също са автоматизирани и разполагат с функции като автоматично подаване на торбички, напълване, пломбиране и маркиране. Цялата автоматична линия за обработка на риба е контролирана от централна система PLC (Програмируем контролер), която координира операцията на всички компоненти, проследява параметрите на процеса в реално време и прави корекции, когато е необходимо, за да гарантира последователно качество на продукта и висока скорост на производство. Благодарение на своята продължителна технология и безшовна автоматизация, автоматичната линия за обработка на риба на KANGBEITE е идеалният избор за големи предприятия за обработка на морски продукти, които искат да повишат продуктивността си и да намалят разходите.

Права на автор © 2025 от firma Shandong Kangbeite Food Packaging Machine Co., Ltd. Политика за поверителност