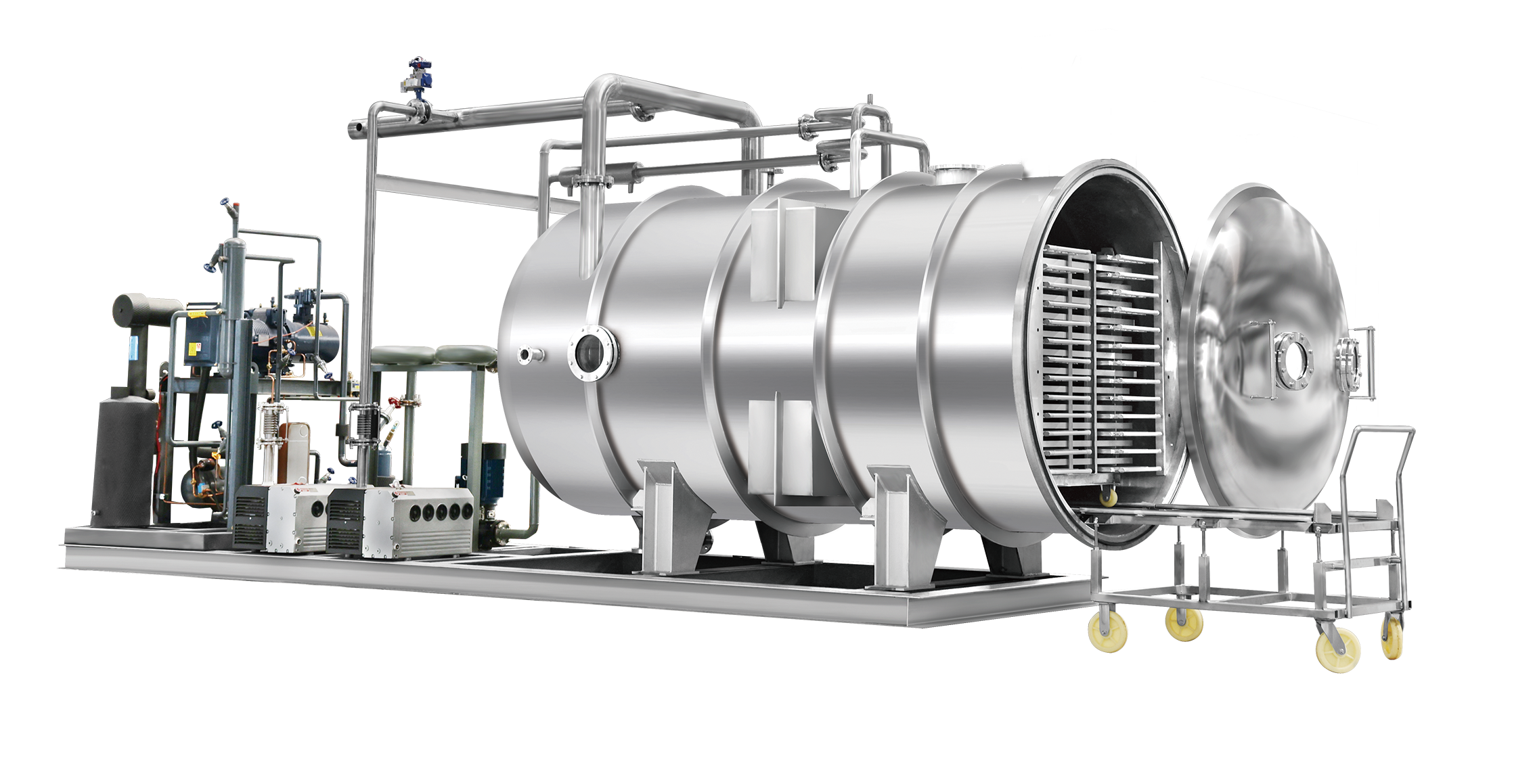

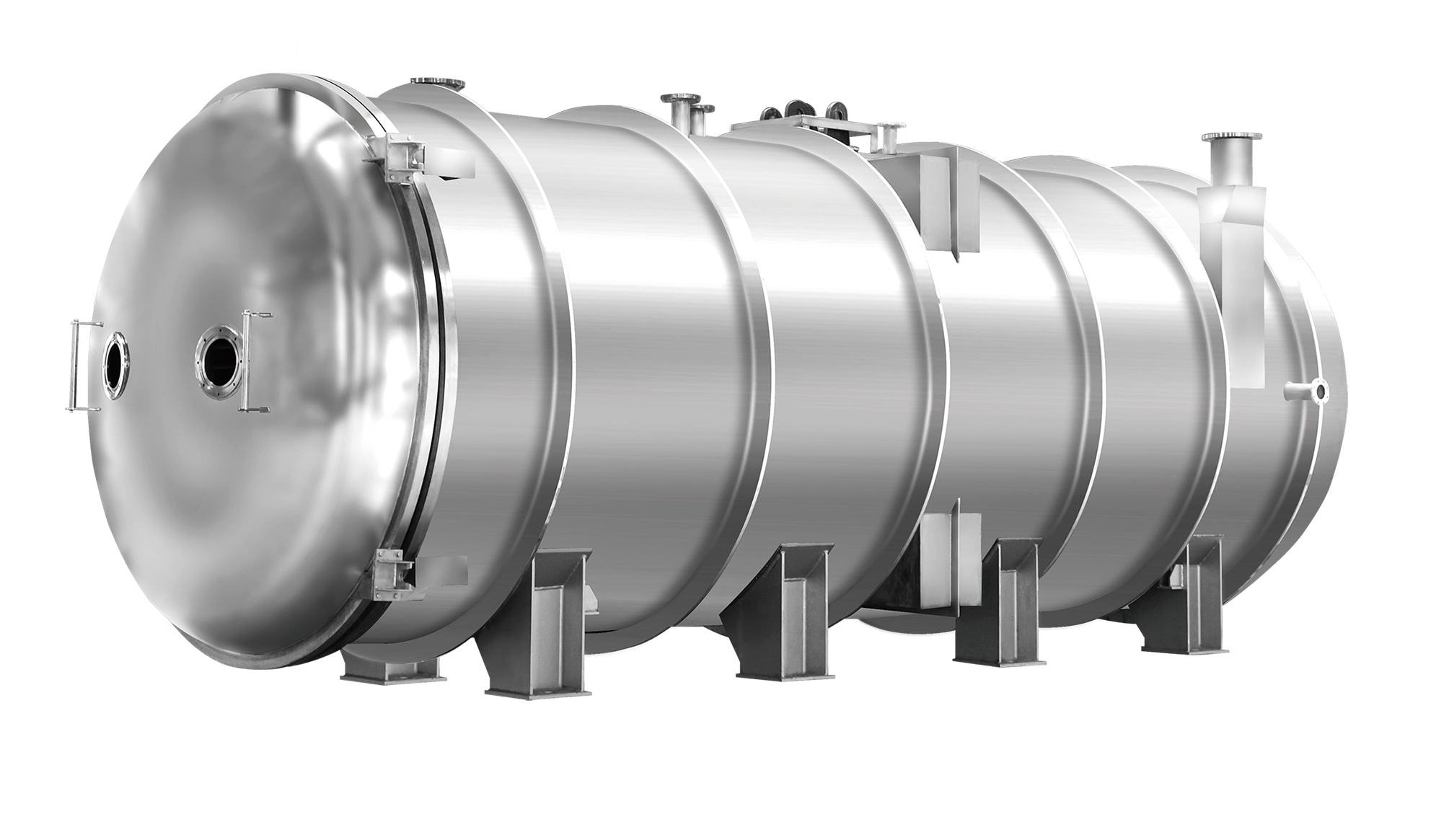

An industrial coffee production line is a high-capacity, fully automated system designed for large-scale manufacturers (multinational brands, instant coffee producers) with daily output exceeding 1000 kg—capable of 24/7 continuous operation to supply global markets. It integrates advanced technologies for efficiency, precision, and compliance with strict international standards (ISO 22000, FDA, EU 10/2011), focusing on minimizing waste, maximizing yield, and preserving coffee quality at scale. The line’s workflow is fully integrated and data-driven: green bean handling begins with automated bulk storage silos (equipped with moisture control systems to maintain 10–12% humidity) and high-speed multi-sensor sorters (2–5 tons/hour, removing 99% of defects via optical, color, and density sensors, including micro-plastics or insect fragments). Roasting uses continuous fluid bed roasters (100–500 kg/hour output) with AI-powered roast profiling—real-time data on bean moisture, color, and temperature adjusts heat input to ensure uniform roast levels (light, medium, dark) across batches. Exhaust gas treatment systems reduce volatile organic compound (VOC) emissions, meeting EU environmental standards (e.g., Euro 6). Post-roasting, beans are cooled via water-cooled conveyors (3–5 minutes to 30℃) and stored in automated silos with nitrogen blanketing to prevent oxidation. For instant coffee production, the line adds extraction (hot water at 90–95℃, optimizing soluble solids yield to 18–22%), vacuum evaporation (concentrating extract to 40–50% solids), and freeze drying (lyophilizers with 500–1000 kg/day capacity, preserving 95% of aroma compounds via low-temperature sublimation). Grinding for ground coffee uses industrial hammer mills (500–1000 kg/hour) with inline sifters to ensure particle size uniformity (±5% variation). Packaging is fully automated and high-speed: VFFS machines (300–500 CPM for pouches), can filling lines (200–300 CPM for 200g–1kg cans), and capsule filling lines (500–1000 capsules/minute for single-serve products), all with nitrogen flushing, automatic labeling, and 100% inline inspection (metal detectors, X-ray machines for foreign material detection). The line is controlled by a centralized Industry 4.0 IoT system that enables predictive maintenance (alerting operators to grinder burr wear or roaster fan issues), real-time yield tracking (reducing waste to <1%), and data logging for regulatory audits. Compliance includes food-contact materials (316L stainless steel, FDA-approved films) and safety features (emergency stop systems, fire suppression for roasters). For manufacturers, this line enables global supply (e.g., supplying instant coffee to 50+ countries), cost optimization (economy of scale reduces unit costs by 20–30%), and rapid product innovation (adding flavored or functional coffee modules in weeks), ensuring competitiveness in the $200B+ global coffee market.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy