Dependable and Requires Minimal Upkeep

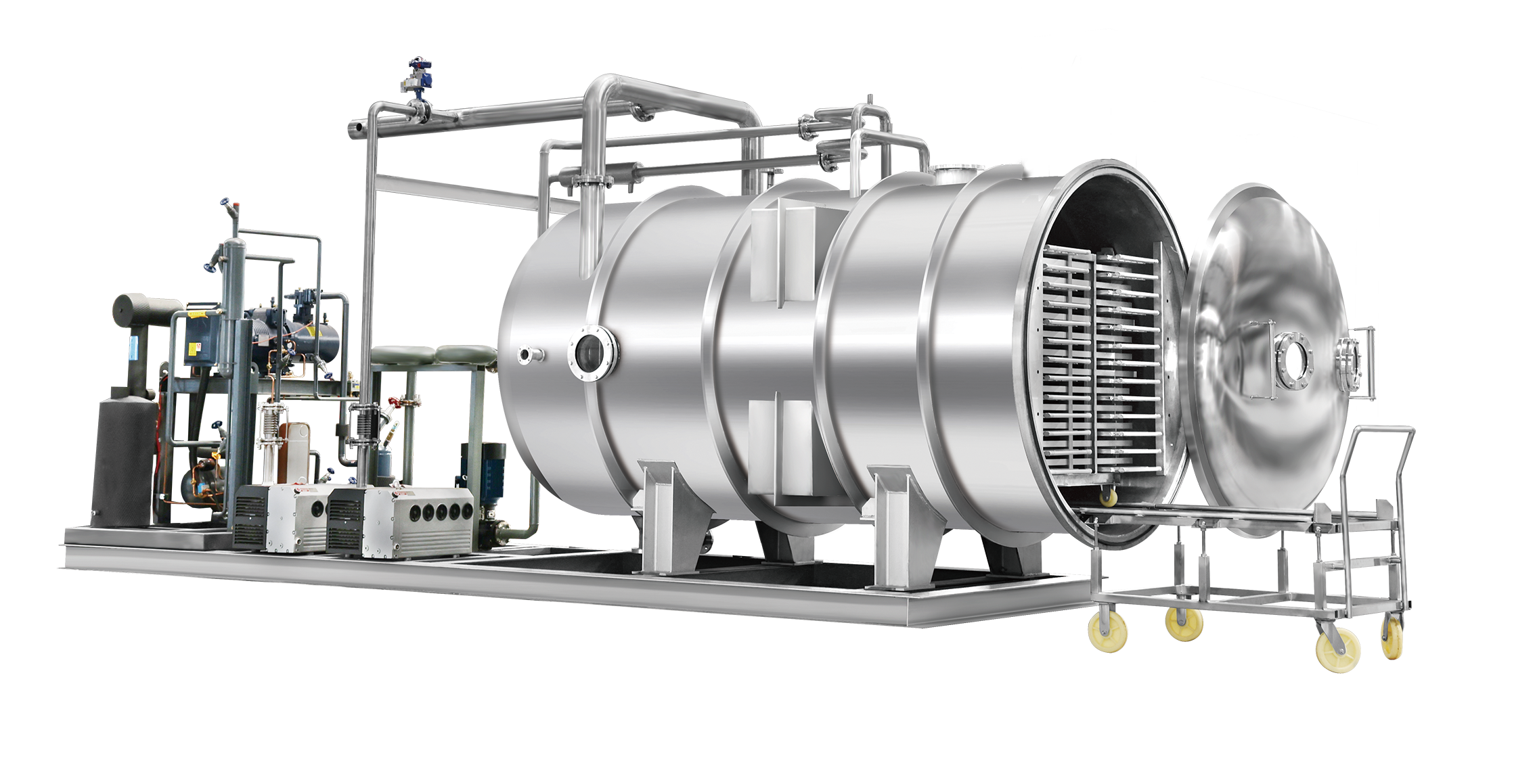

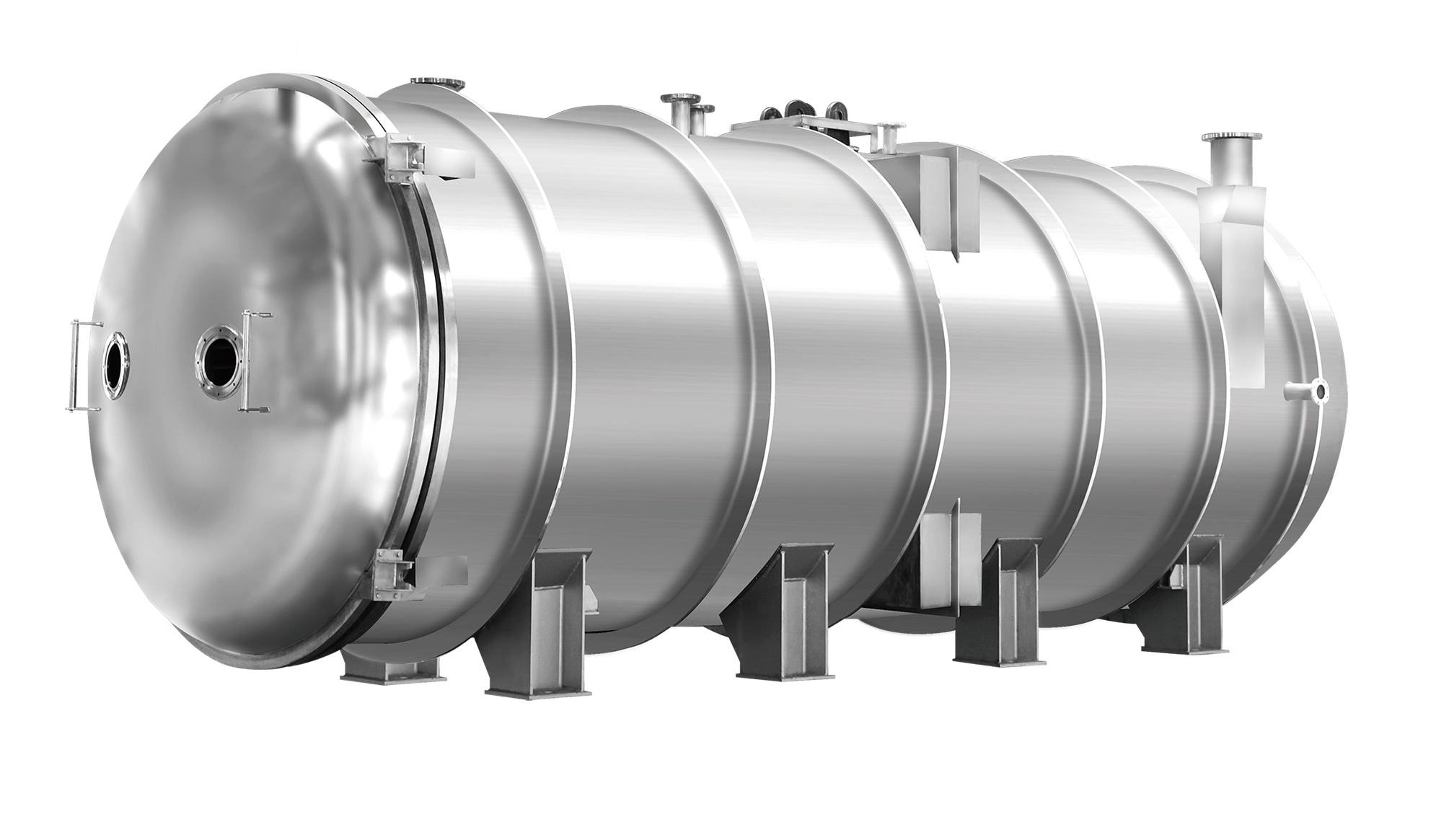

Our coffee production line integrates components of superior quality. This guarantees dependable operation throughout the useful life of the system. Our line is built to last, withstanding the high demands associated with continuous operation in fast-paced production settings. In addition, streamlined design improves maintenance efficiency. Maintenance is simplified due to user-friendly design, allowing technicians to conduct periodic inspections, cleaning, and repairs easily. Maintenance can be performed easily, preventing unexpected failures and minimizing work stoppages. With reduced upkeep demands, coffee producers can concentrate on their primary business of delicious coffee production while managing expenses effectively.