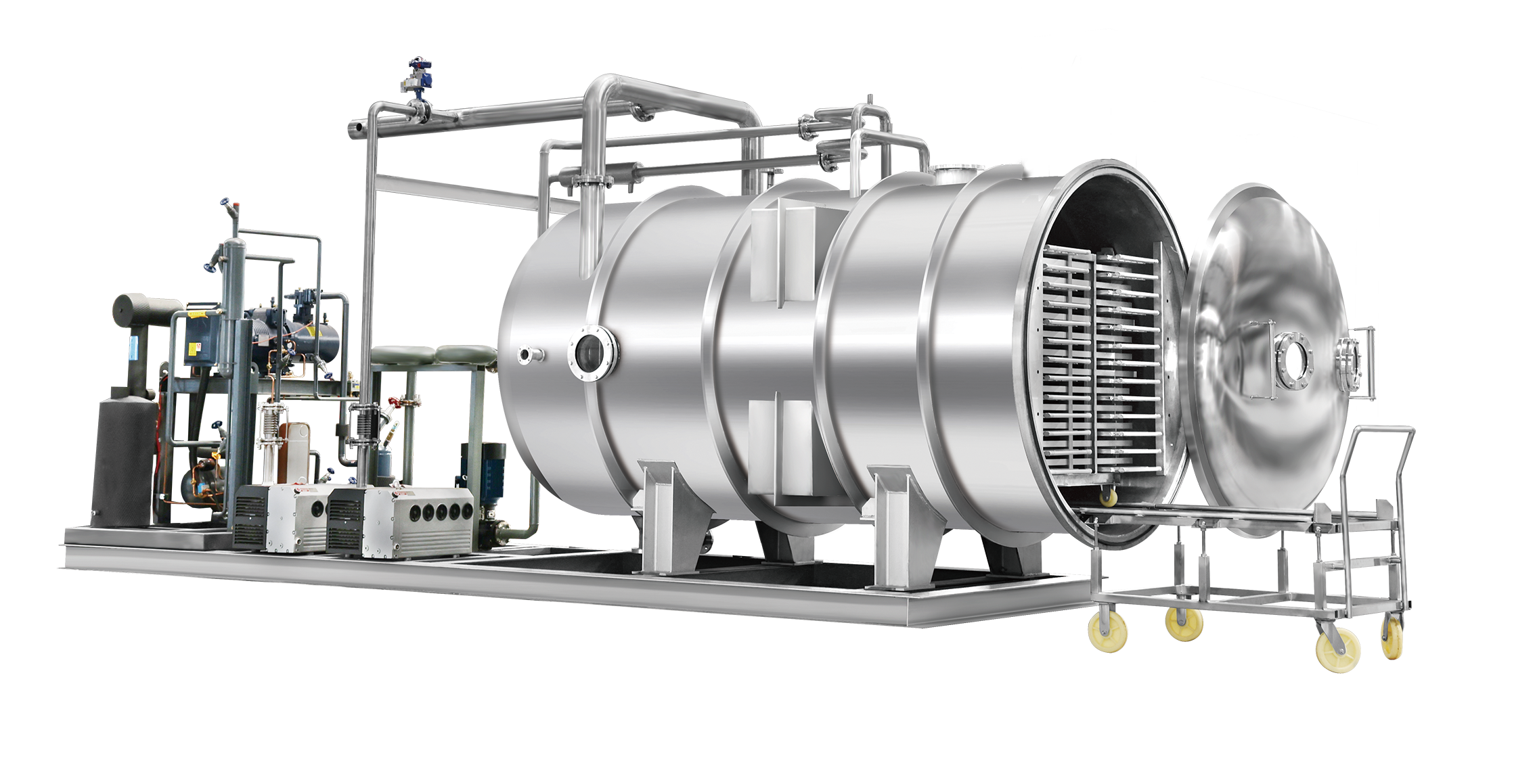

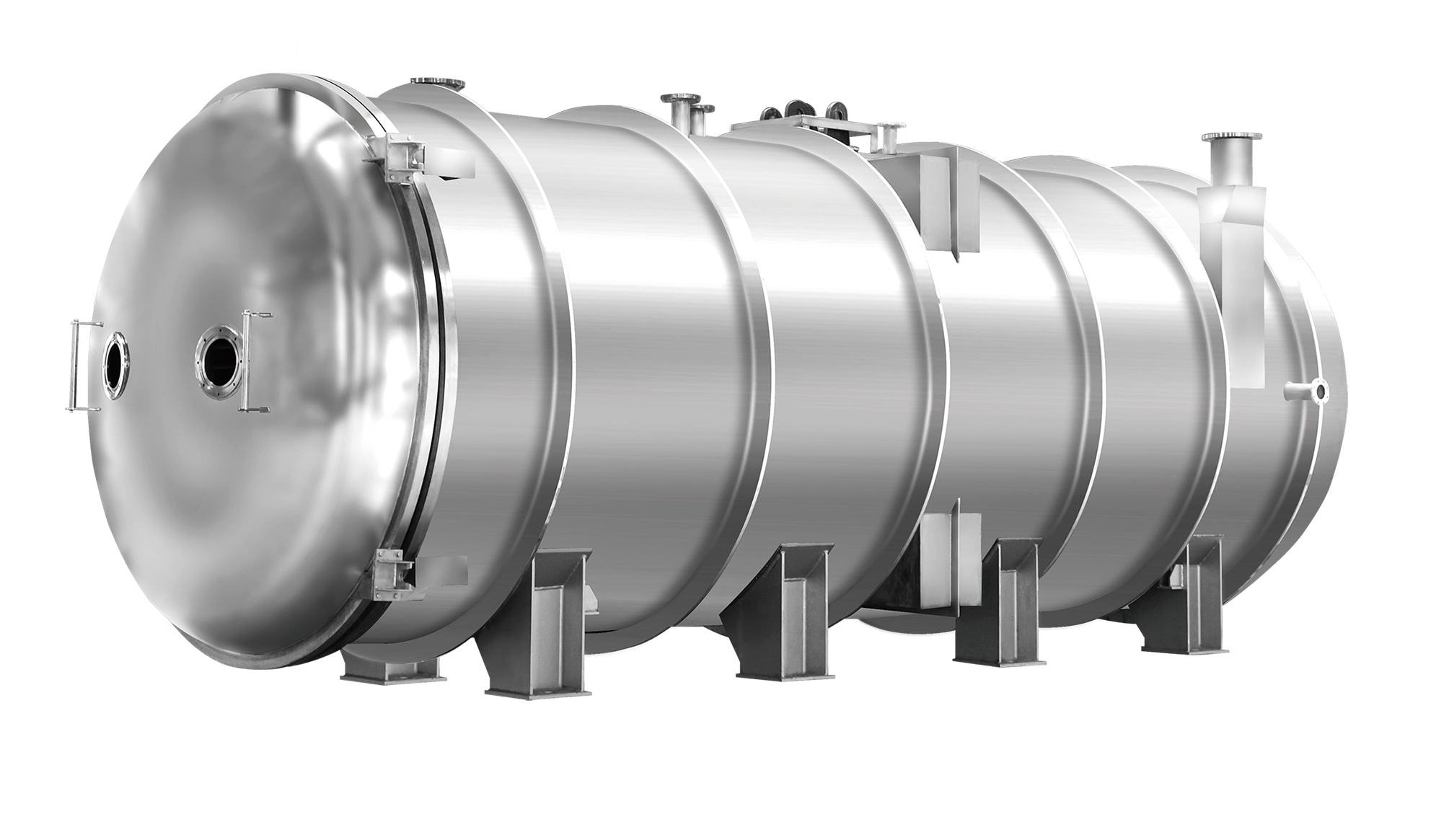

A coffee production line supplier is a specialized provider of integrated equipment, technical support, and turnkey solutions for coffee manufacturers, covering the entire coffee production lifecycle: green bean processing, roasting, grinding, extraction, concentration, freeze drying (for instant coffee), and packaging. Unlike generic equipment suppliers, they focus on coffee-specific challenges: preserving aroma compounds (volatile and heat-sensitive), ensuring consistent roast profiles, and complying with food safety standards (FDA, EU 10/2011, ISO 22000). Their core offerings include customizable line designs tailored to production scale (small: 50-200 kg/hour for artisanal roasters; large: 500-2000 kg/hour for industrial instant coffee producers) and product type (roasted beans, ground coffee, instant coffee, cold brew concentrate). Key equipment in their portfolio includes: green bean sorters (optical sensors to remove defective beans, stones, or foreign materials), drum roasters (with precise temperature control: 180℃-220℃, adjustable rotation speed to ensure even roasting), grinders (conical burr or hammer mills, with particle size control: 100-1000 μm for different brewing methods), extraction systems (hot water or cold brew, with pressure control to maximize soluble solids yield: 18%-22%), and freeze dryers (for instant coffee, preserving 95% of aroma). Beyond equipment, reputable suppliers offer end-to-end services: feasibility studies (matching line capacity to market demand), installation (by certified technicians), training (operator and maintenance teams), and after-sales support (spare parts supply within 48 hours for critical components, remote troubleshooting via IoT). They also ensure compliance with regional standards: CE marking for Europe, UL certification for North America, and JIS for Japan. Quality control is embedded in their solutions—integrated metal detectors, weight checkers, and aroma monitoring systems (gas chromatography for instant coffee) to ensure product consistency. For coffee manufacturers, partnering with a specialized supplier reduces project risk: it eliminates compatibility issues between equipment (e.g., roaster output matching grinder capacity), shortens time-to-market (turnkey lines installed in 3-6 months), and ensures access to the latest technology (e.g., energy-efficient roasters, IoT-enabled monitoring). It also supports scalability—suppliers can upgrade lines (e.g., adding a freeze dryer for instant coffee) as manufacturers expand into new product categories, critical for competing in the $200B+ global coffee market.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy