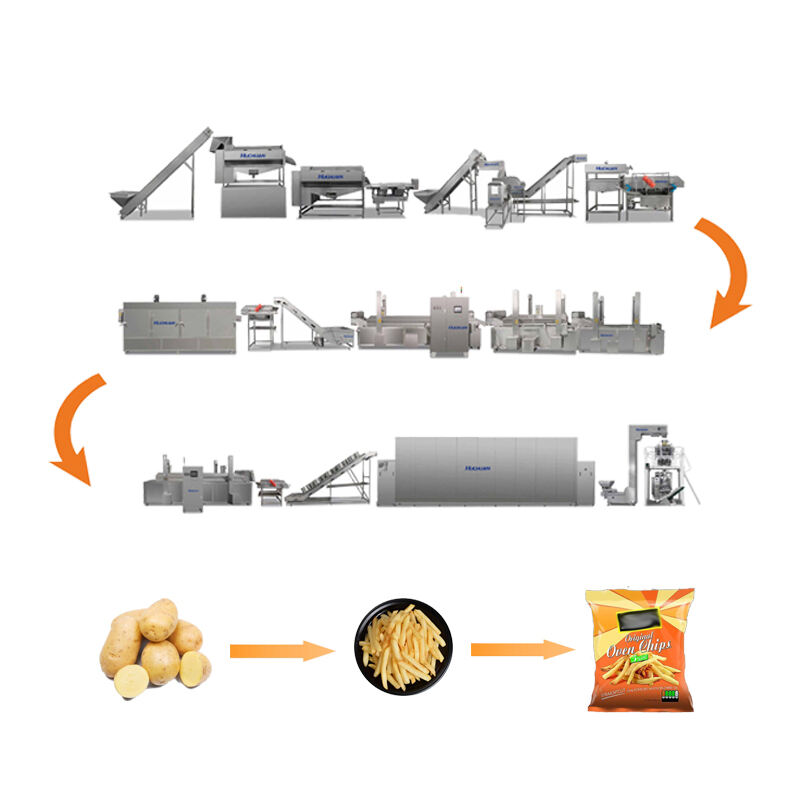

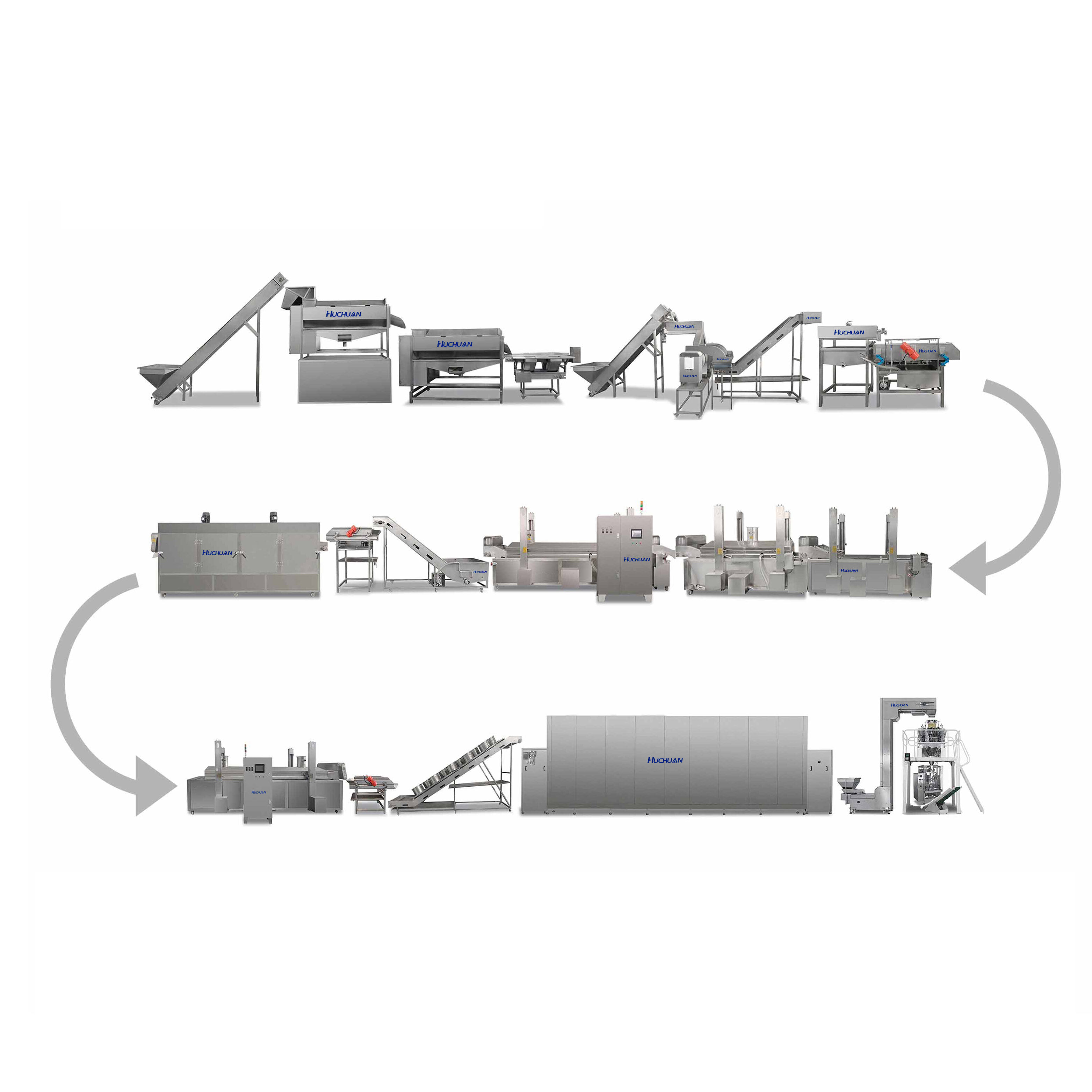

En fullt automatisk produktionslinje för pommes frites är ett integrerat system som hanterar varje steg i potatisförädlingsprocessen – från rengöring av råpotatis till färdiga frysta eller förpackade pommes frites som är klara att äta – med minimal mänsklig påverkan. Den är utformad för medelstora till stora förädlare (leverantörer till snabbmatsrestauranger, varumärken i detaljhandeln) med en daglig produktion på 500–2000 kg. Linjen kombinerar hastighet, konsekvens och livsmedelssäkerhet för att möta den höga efterfrågan på standardiserade pommes frites samtidigt som textur (krispig yta, fluffig inre) bevaras och spill minskas. Linjens arbetsflöde är sömlöst och automatiskt: råpotatis töms i en bulkhink och transporteras till en förvasktank (roterande borstar + högtrycksvatten) för att ta bort smuts och lösa skinn. Ett avlägsnandessystem för stenar (som använder vattentäthet för att separera stenar från potatisar) förhindrar skador på utrustningen och säkerställer livsmedelssäkerhet. Skalning sker med ett ångskalningssystem (100–105°C ånga i 40–60 sekunder) eller mekaniska skalare (abrasiva rullar) beroende på potatisens sort – ångskalning är mjukare (spill <5 %) för högkvalitativa pommes frites, medan mekanisk skalning är kostnadseffektiv för större produktion. Efter skalning inspekteras potatisarna med en optisk sorterare (som tar bort skalade potatisar med defekter som blåmärken eller ögon) innan skärning. Skärmodulen använder en flerbladig roterande skärare (justerbar bladavstånd: 6–12 mm för standard pommes frites, 10–15 mm för tjockare snitt) med ett vattenspridsystem för att ta bort överskott av stärkelse – avgörande för att förhindra att pommes frites klibbar ihop och säkerställa jämn stekning. Blanchering är ett viktigt kvalitetssteg: pommes frites sänks ner i 80–90°C varmt vatten i 2–3 minuter för att gelatinisera stärkelsen (förbättrar krispigheten) och inaktivera enzymer (förhindrar mörkning). En kylbana (kyld vatten, 0–5°C) stoppar matningen, följt av ett vattenavskiljningssystem (luftblåsare eller centrifuger) för att ta bort ytlig fuktighet. För frysta pommes frites använder linjen en IQF-linje (Individual Quick Freezing) (-35°C till -45°C, frysnings tid på 8–12 minuter) för att frysa pommes frites individuellt, vilket säkerställer att de inte klumpar ihop. För pommes frites som är klara att äta används en kontinuerlig stekpanna (175–190°C vegetabiliskt olja, stektid på 2,5–3,5 minuter), med ett integrerat oljefiltreringssystem för att ta bort matpartiklar och upprätthålla oljekvaliteten. En deoljerare (centrifugal eller luftblåsning) minskar fettinnehållet till 15–20 % för hälsosammare alternativ. Förpackningen är fullt automatisk: frysta pommes frites vägs och packas i fuktskyddande påsar (100–150 CPM) eller kartonger med hjälp av en case packer, medan pommes frites som är klara att äta använder modifierad atmosfär (MAP, 70 % N₂, 30 % CO₂) för att förlänga hållbarheten till 5–7 dagar. Kvalitetskontroll är integrerad genom hela processen: metallspetsar, kontrollvågar (±1 g precision) och täthetsprovare säkerställer efterlevnad av livsmedelssäkerhetsstandarder (FDA, EU 1333/2008). Alla livsmedelskontaktdelar är tillverkade av rostfritt stål i kvalitet 304, med CIP-system för automatisk rengöring för att förhindra korskontamination. För förädlare säkerställer denna linje konsekvent storlek, textur och smak på pommes frites (batch-till-batch variation <2 %), uppfyller kraven från snabbmatskedjor (t.ex. enhetlig längd för frysautomater) och kan skalas upp för att hantera toppar i efterfrågan (t.ex. högsäsonger).

Upphovsrätt © 2025 av Shandong Kangbeite Food Packaging Machine Co., Ltd. Integritetspolicy