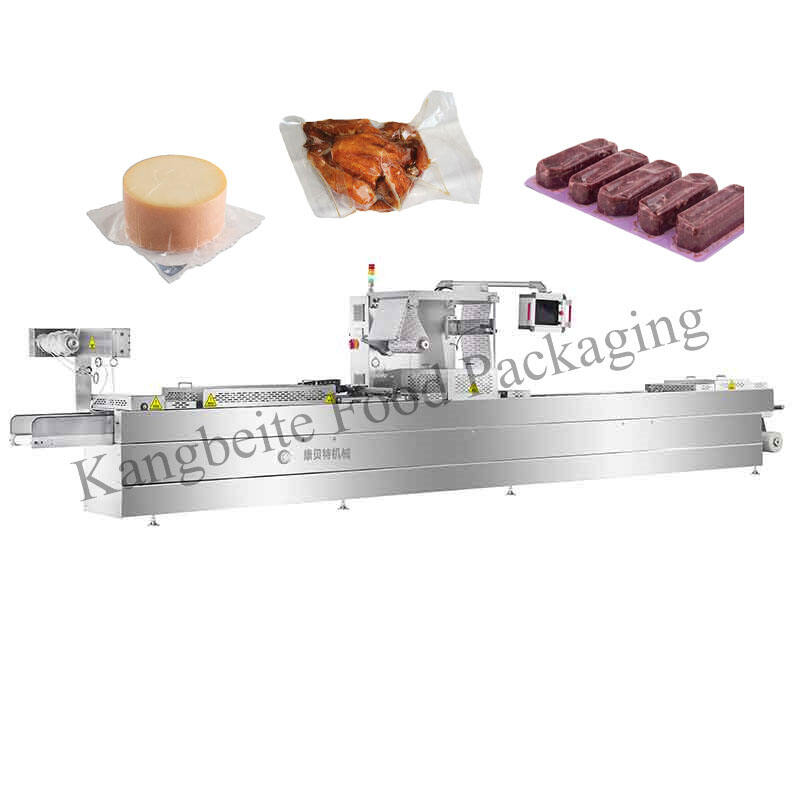

Nova modela mašine za termoformiranje predstavlja skok naprijed u tehnologiji pakovanja, kombinujući svestranost, efikasnost i napredne karakteristike kako bi zadovoljila evoluirajuće potrebe prehrambene industrije. Ova mašina automatski obavlja cijeli proces pakovanja, od formiranja donjeg sloja folije do zatvaranja gornjeg sloja, sa minimalnim učešćem operatera. Proces termoformiranja koristi toplotu za oblikovanje donje folije u prilagođene šupljine, pri čemu se prilagođava proizvodima različitih veličina i oblika, od nepravilno oblikovanih voćki do porcijonisanog mesa. Ključne inovacije u novoj modeli uključuju poboljšane sisteme grejanja sa preciznom kontrolom temperature, što osigurava stabilno oblikovanje čak i tankih ili termoosjetljivih folija. Mogućnosti vakuumiranja i punjenja gasom omogućavaju i vakuumsko pakovanje i pakovanje u modificiranoj atmosferi (MAP), čime se produžuje rok trajanja prilagođavanjem gasnog sastava (najčešće mješavina dušika, kisika i ugljen-dioksida). Napredni senzori prate napon folije, kvalitet oblikovanja i integritet zatvaranja, s mogućnošću trenutnih prilagodbi radi smanjenja otpada. Nova modela takođe ima poboljšanu energetsku efikasnost, gdje izolovani grejni elementi i pogoni promjenjivih brzina smanjuju potrošnju energije. Njena modularna konstrukcija omogućava jednostavnu integraciju s drugom opremom na proizvodnoj liniji, kao što su vagovi i uređaji za označavanje, stvarajući neprekidan radni tok. Prilagođenost najnovijim propisima o sigurnosti hrane, uključujući standarde FDA i EU, osigurana je korištenjem materijala prihvatljivih za kontakt s hranom i higijenskim dizajnom. Bez obzira na to da li se koristi za pakovanje spreman za prodaju ili za industrijsko pakovanje u velikim količinama, nova modela mašine za termoformiranje nudi fleksibilnost i visok učinak, čime je postaje vodeći izbor za savremene proizvođače hrane.

Autorska prava © 2025 Shandong Kangbeite Food Packaging Machine Co., Ltd. Pravilo o privatnosti