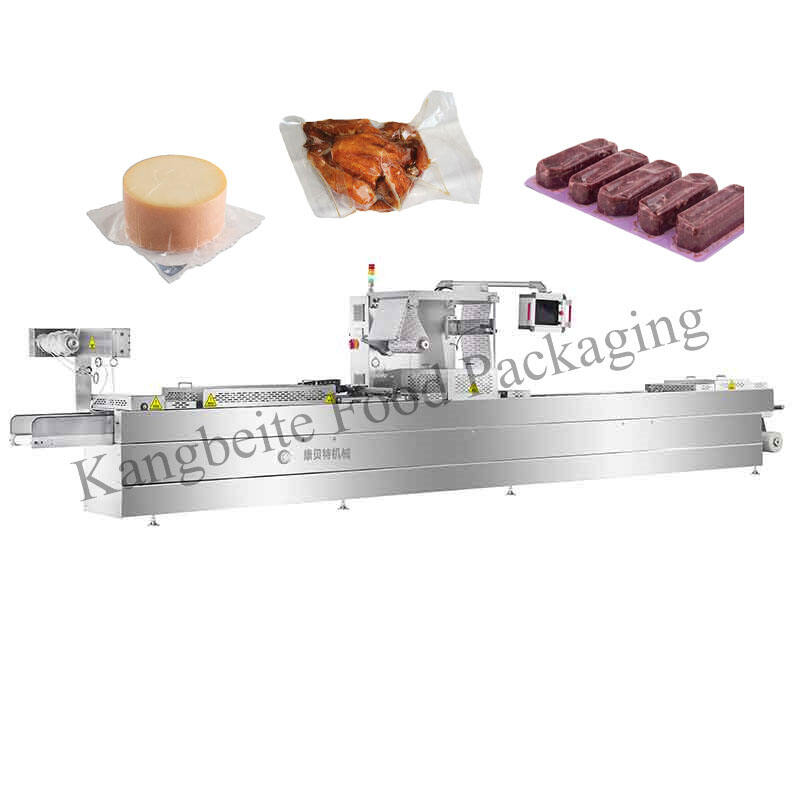

Bizning ko'p maqsadli termoformalash jihozi, paketlash talablari uchun inkar qilinmaydigan va innovatsion yechim hisoblanadi. Ushbu jihoz plastik materiallarning turidan qat'i nazar qilib olib, turli hajmdagi paketlarni ishlab chiqarish uchun dizaynlangan bo'ladi, bu esa uni ovqat mahsulotlaridan xizmat xizmatlari mahsulotlariga qadar barcha narsani paketlash uchun qulay qiladi. Termoformalash jarayoni plastik plitkani issiqlovishdan iborat, unda belgilangan shaklda formaga o'tkaziladi va keyin qoldiq materialni kesib tashlaydi. Bizning ko'p maqsadli jihoz moldizayndagi esneklikka ega bo'lib, mahsulotning mazmuniga va funktsionalligiga qo'shimcha ko'rinish beruvchi shakllardagi paketlarni yaratish imkonini beradi. U sovabr temperature boshqaruv tizimlari bilan tenglangan, to'g'ri issiqlovish va sochish uchun muammili holatda formulalash natijalarini ta'minlaydi. Avtomatik plastik plitka to'ldirish va kesish mashinasi ishlab chiqarishni oshiradi, manual kasblarni kamaytiradi va materialni ishlatib tashlashni minimal holatga keltiradi. Shuningdek, bizning ko'p maqsadli termoformalash jihozimiz rivojlangan saqlash mudati uchun gaz yoqish, brendlash uchun bosish va ko'rinishga qo'shimcha ko'rinish berish uchun embossing kabi turli xil ixtiyoriy funksiyalar bilan integrallashtirilishi mumkin. Foydalanuvchi uchun yaxshi interfeys va oson almashtirish mumkin bo'lgan moldizayn tizimi bilan, ushbu jihoz paketlash variantlarini ko'paytirish va bozordagi o'zgaruvchan talablariga javob berishni istaganchilar uchun arzon va effektiv yechimni taqdim etadi.

Huquqiy to'liqlik © 2025 Shandong Kangbeite Taom Pakerlash Masinasi Kompaniyasi Maxfiylik siyosati