Presná kontrola kvality

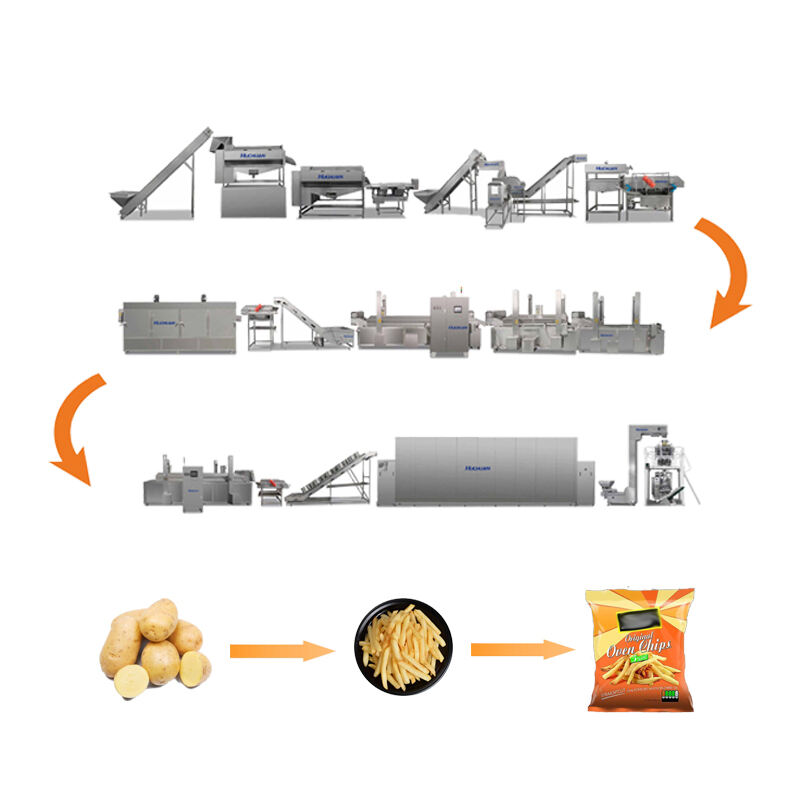

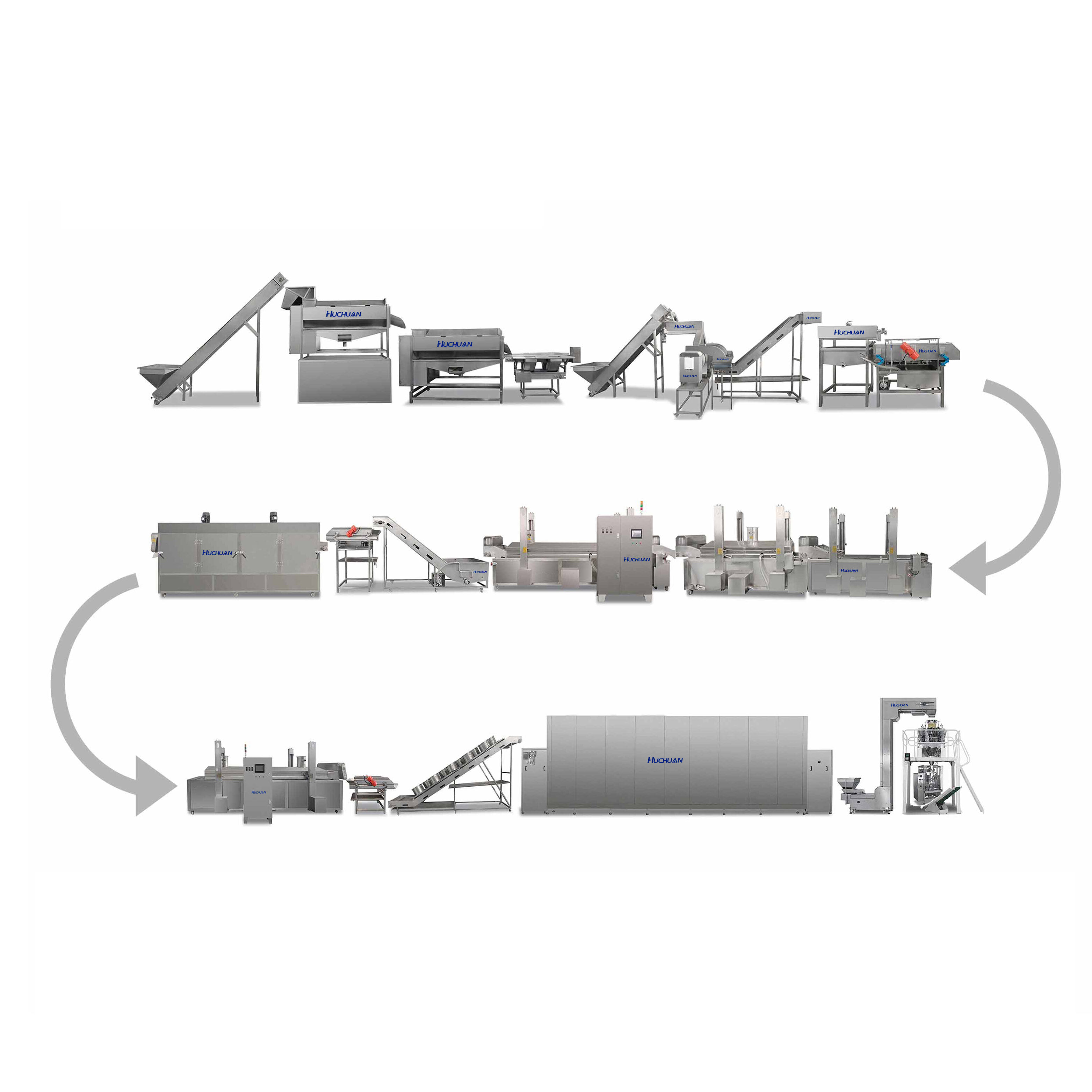

Každá úroveň výroby zabezpečuje kvalitu a bezpečnostné požiadavky pre potravinársky priemysel. Rovnomerná hrúbka krupiek je zabezpečená lasereckou rezačnou sústavou a absorpcia tuku/predpripojenie texturovacej stabilizácie pomocou teplotne kontrolovaného vody sa uskutočňuje počas blančovania v tunele. Inteligentné fričiarske moduly s reálnym časovým monitorovaním kvality oleja automaticky prispôsobia teplotu a filtračiu na zachovanie chrupavosti a chuti krupiek. Finálna balenie prechádza kontrolou kvality na detekciu kovu a kontrolu hmotnosti, overujúc dodržiavanie medzinárodných štandardných potravinárskej bezpečnostnej regulácie CE, ISO 9001, QS.