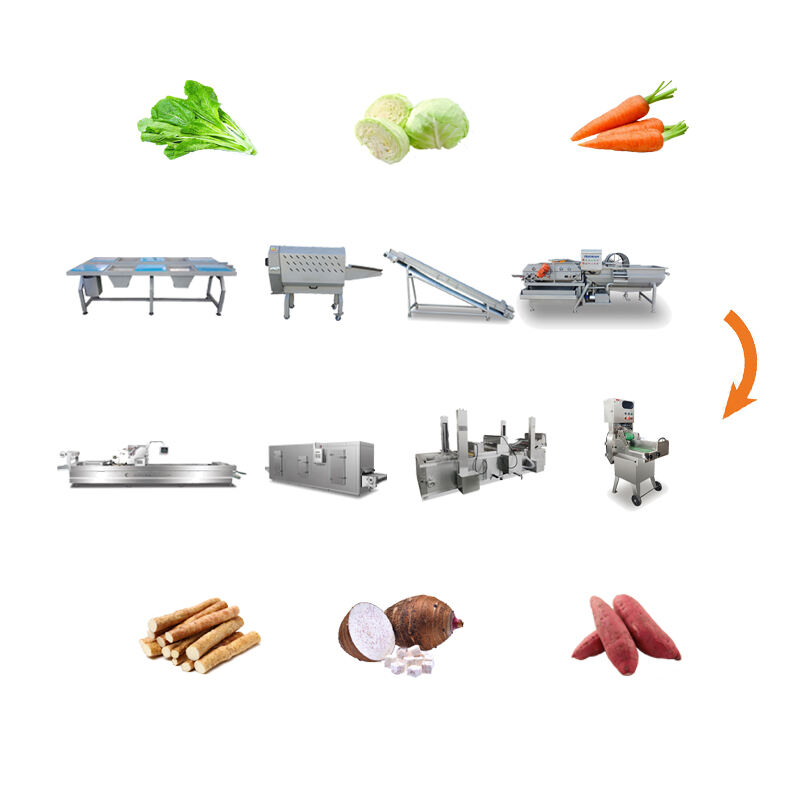

Dispoñemos dunha variedade de máquinas de lavado de hortaliças para todos os tamaños de empresas. Desde operacións a pequena escala, como os mercados de productores, ata procesadores a gran escala, os nosos modelos mini, de tamaño de mesa, e sistemas de grao industrial atenden a todos. O noso equipo utiliza tecnoloxía de vanguardia para garantir a calidade, como a limpeza ultrassónica para artigos delicados e unha limpeza a alta presión para hortaliças difíciles de limpar. Os compoñentes da máquina de lavar son tamén non corrosivos, de grao alimentario, inmunes á degradación e con unha vida útil prolongada. As nosas máquinas de lavado garantizarán que as súas hortaliças teñan un estándar insuperable de seguridade e limpeza, dándolle unha vantaxe competitiva no mercado. Todo o equipo moderno ofrece interfaces fáciles de maneixar e expulsan os residuos do sistema.

Dereitos de autor © 2025 por Shandong Kangbeite Food Packaging Machine Co., Ltd. Política de privacidade