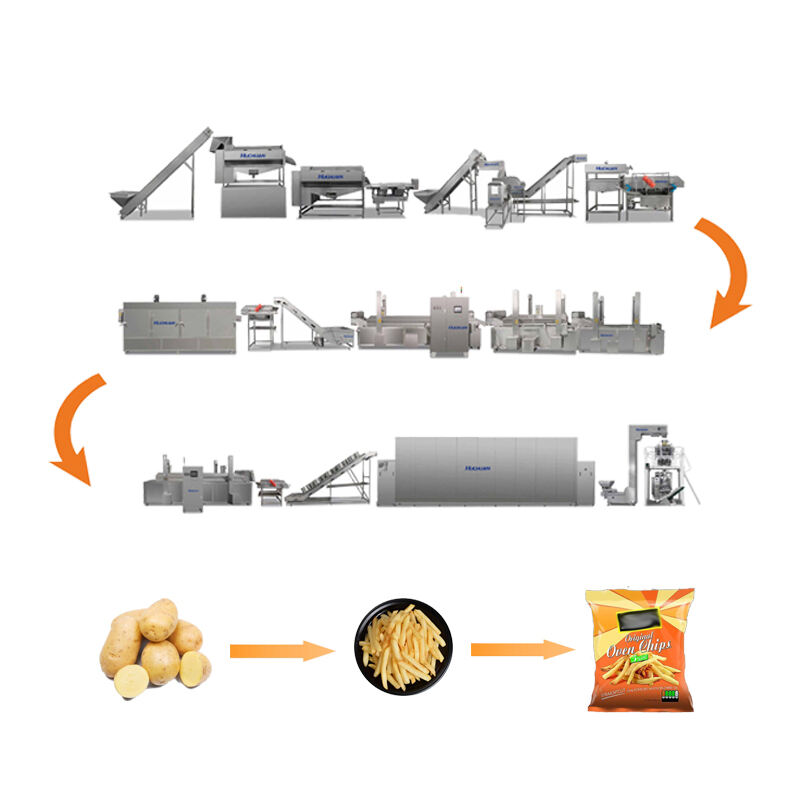

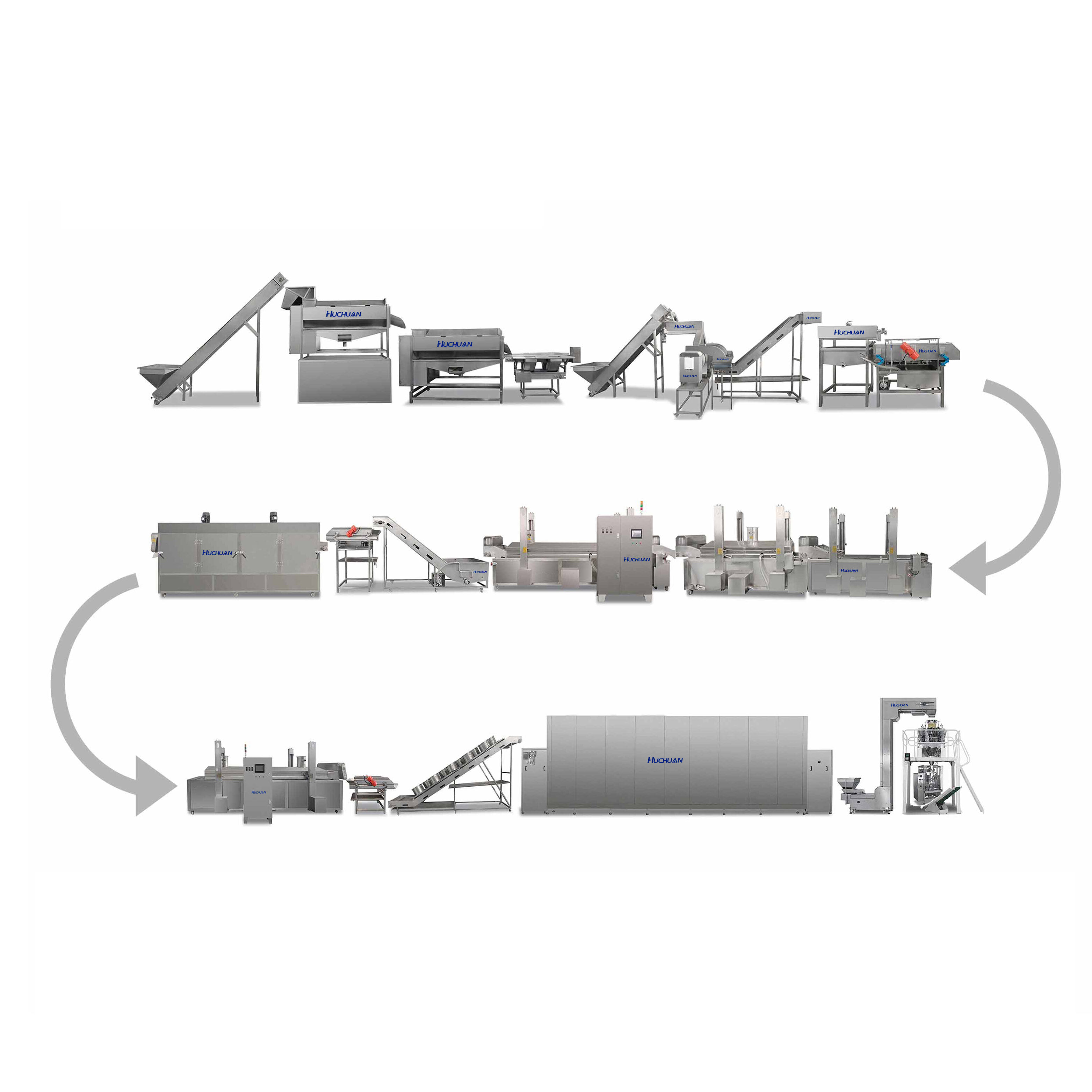

Linija za proizvodnju industrijskih krompirića je sistem visokog kapaciteta, potpuno automatizovan, dizajniran za proizvođače velikih razmjera (globalne mreže brze hrane, multinacionalne trgovinske marke) sa dnevnom proizvodnjom većom od 2000 kg – sposoban za neprekidni rad 24/7 kako bi se opslužile globalne tržišne potrebe. Ona uključuje naprednu tehniku, energetsku efikasnost i strogo pridržavanje propisa kako bi proizvodila standardizovane, kvalitetne krompiriće, uz minimalne troškove i štetne uticaje na okolinu. Tok rada na liniji optimiziran je za velike količine i preciznost: sirov krompir dolazi u većim količinama (kamioni ili željezničke cisterne) i skladišti se u silosima sa kontrolisanom klimom (10–15°C, vlažnost 85–90%) radi očuvanja svežine. Automatski dozator za veće količine prebacuje krompir na višestepeni sistem pranja: predpranje (mlaz vode pod visokim pritiskom), glavno pranje (rotirajuće četke) i završno ispiranje (voda sa hlorom, 50–100 ppm) radi uklanjanja prljavštine, pesticida i mikroba. Sistemi za uklanjanje kamenja i brkanja (uklanjanje korijenskih dlačica) sprječavaju oštećenje opreme i osiguravaju bezbjednost hrane. Luštenje se vrši u komorama za luštenje parom velikih razmjera (sposobne za preradu 500–1000 kg/partija) koje koriste paru pod visokim pritiskom (105–110°C) za omekšavanje kore, koja se potom uklanja gumenim valjcima – otpad je <4%, a proces čuva meso krompira radi maksimalnog prinosa. Nakon luštenja, sistem za optičko sortiranje (višekamera, visoka brzina) uklanja oštećene krompire (modrice, oči, zelene mrlje) u količinama od 1–2 tona/sat. Rezanje se obavlja industrijskim rotacionim noževima (višestruke glave noževa, kapacitet 500–1000 kg/sat) sa regulisanim razmakom noževa (6–15 mm) za proizvodnju standardnih, debelih ili valovitih krompirića. Neprekidni sistem uklanjanja škroba (protivtok vode) ispire višak škroba, smanjujući apsorpciju ulja i poboljšavajući hrskavost – voda se reciklira (80%+ povrat) radi smanjenja otpada. Blanširanje se vrši u tunelu sa vrućom vodom (85–95°C, vrijeme zadržavanja 2–4 minute) sa zonama temperature radi osiguranja uniformne želatinizacije škroba i inaktivacije enzima. Krompirići se potom hlade u tunelu sa rashlađenom vodom (0–4°C) i osušuju pomoću sušilica sa vazduhom visoke brzine (uklanja 90% vlažnosti sa površine). Za smrznute krompiriće, linija koristi spiralni sistem IQF (Individual Quick Freezing) na temperaturama od -40°C do -50°C, sa vremenom smrzavanja od 5–10 minuta, sposoban za obradu 1–5 tona/sat, osiguravajući individualno smrzavanje i sprječavajući stvaranje grudvica. Za dodatno obrađene proizvode (npr. začinjene krompiriće), neprekidni aplikator začina (praškasti ili tečni) ravnomjerno dodaje okusne arome. Pakovanje je potpuno automatizovano i povezano sa skladišnim sistemima: smrznuti krompirići se vagaju, pakuju u vrećice za maloprodaju od 2,5 kg do 10 kg ili u kartonske kutije za veleprodaju od 20 kg do 50 kg i paletizuju pomoću robotskih ruku za isporuku. Kontrola kvaliteta uključuje metalne detektore u liniji, rendgenske aparate (za detekciju stranih tijela), kontrolne vage (tačnost ±0,5 g) i analizatore vlažnosti (praćenje konačne vlažnosti: 2–4% za smrznute krompiriće). Linija odgovara globalnim standardima (ISO 22000, FDA, EU 1333/2008) i uključuje značajke za uštedu energije (povrat toplote iz frižidera/blanšera, motori promjenjivih brzina) radi smanjenja operativnih troškova. Za proizvođače, ova linija omogućava globalnu isporuku (zadovoljava potražnju lanaca brze hrane sa hiljadama lokacija), kontinuiran kvalitet (ključno za ugled marke) i efikasnost po pitanju troškova (ekonomija razmjera smanjuje jedinične troškove za 25–35%), čime postaje ključna komponenta globalnog tržišta krompirića vrijednog više od 30 milijardi dolara godišnje.

Autorska prava © 2025 Shandong Kangbeite Food Packaging Machine Co., Ltd. Pravilo o privatnosti