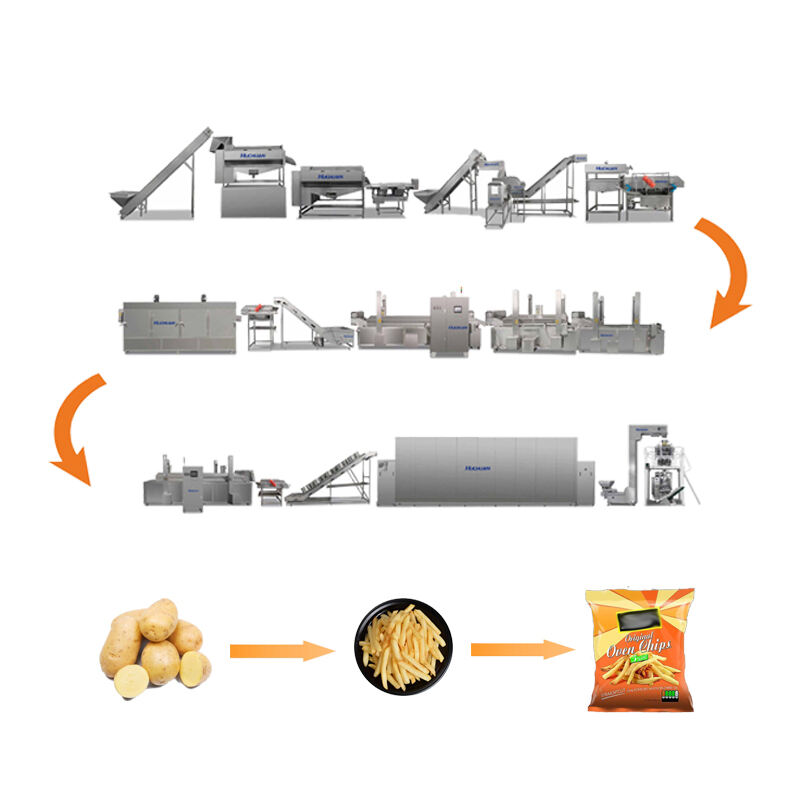

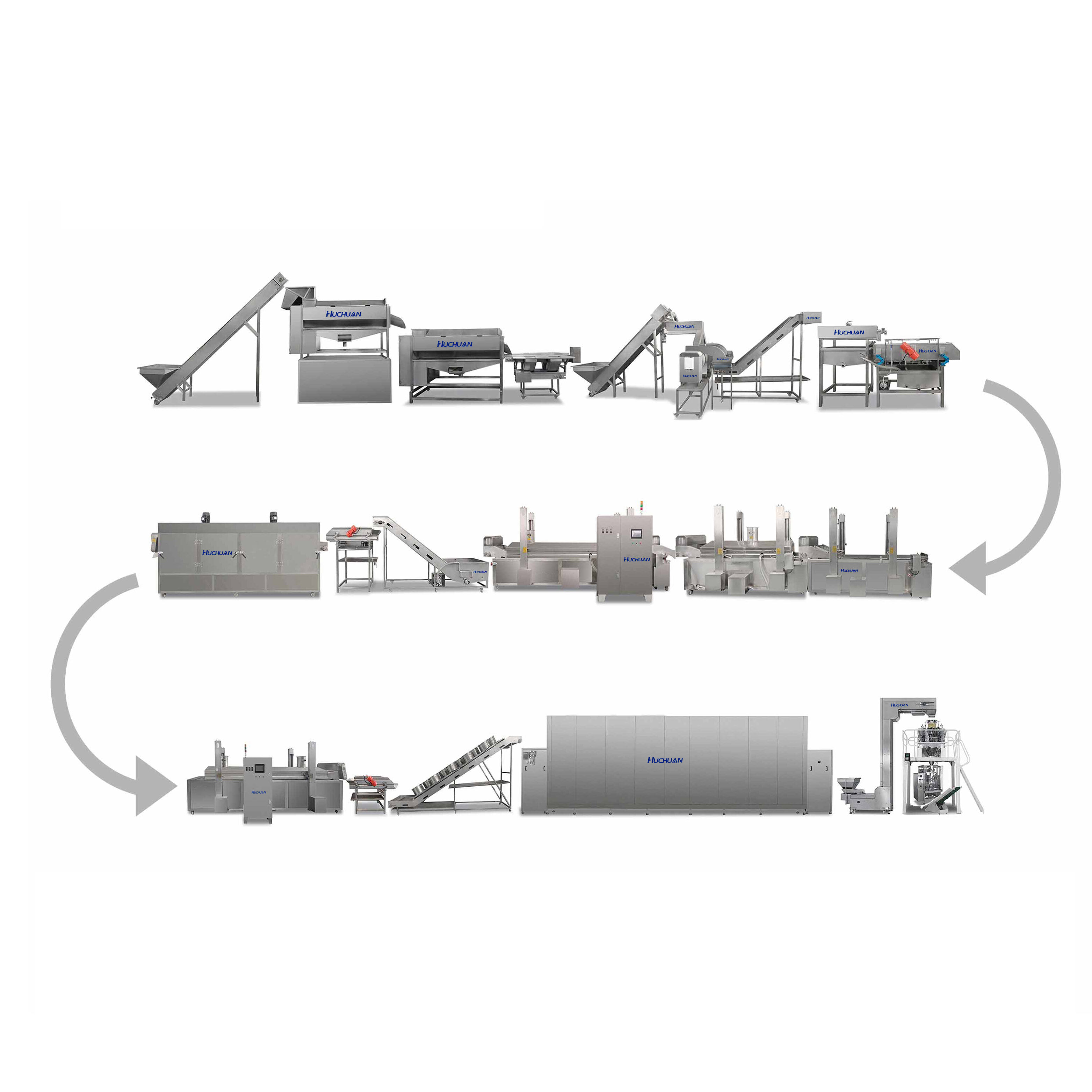

U prehrambenoj industriji, gdje se često zahtijeva velkoskalna proizvodnja kako bi se ispunile tržišne potrebe, visokokapacitetska linija za proizvodnju krumpira predstavlja neocjenjivu imovinu. Ovaj tip linije je konstruisan da obradi velike količine krumpira, pretvarajući ih u visokokvalitetne krupice brzo i učinkovito. Linija počinje s jačnom sustavom za prijem i sortiranje krumpira koji može obraditi velike količine krumpira odjednom. Napredni senzori i mehanički sustavi za sortiranje brzo razdvajaju krumpire prema veličini, kvalitetu i bilo kojim nedostatcima, osiguravajući da se dalje procesiraju samo prikladni krumpiri. Jedinicu za pranje i školjanje dizajnirano je sa visokoprotocnim vodnim sustavima i učinkovitim tehnologijama školjanja kako bi se krumpiri očistili i pripremili za rezanje u najkraćem mogućem vremenu. Sektar za rezanje ima više brzih režnih žlijeva raspoređenih na način koji maksimizira protok. Ti žlijevi mogu proizvesti veliku količinu krupica u različitim stilovima istovremeno. Nakon rezanja, krupice prolaze kroz neprekidni proces blanžiranja i sušenja, koji je optimiziran za visokokapacitetsku proizvodnju. Fryer sustav je jedan od ključnih komponenti visokokapacitetske linije. Sastoji se od velikoskalnih fryera s moćnim grejanjskim elementima i učinkovitim sustavima cirkulacije ulja. Ti fryeri mogu kuhati veliku količinu krupica ravnomerno i brzo, održavajući konstantnu kvalitetu čak i pri visokim stopama proizvodnje. Nakon kuhanja, krupice se brzo hladene a zatim prebacuju u područje ambalaže. Ambalažno opremljena na visokokapacitetskoj liniji može ispuniti i zaklopiti veliki broj ambalaža po minuti, s opcijama za različite veličine i vrste ambalaže. Tijekom cijelog procesa, linija je opremljena naprednim sustavima nadzora i upravljanja. Ti sustavi neprestano praću ključne parametre poput temperature, brzine i obujma proizvodnje, osiguravajući da visokokapacitetska linija za proizvodnju krupica radi glatko, učinkovito i s minimalnim vremenom neaktivnosti, čime postaje idealan izbor za velikoskalne proizvođače hrane.

Autorska prava © 2025 Shandong Kangbeite Food Packaging Machine Co., Ltd. Pravilo o privatnosti