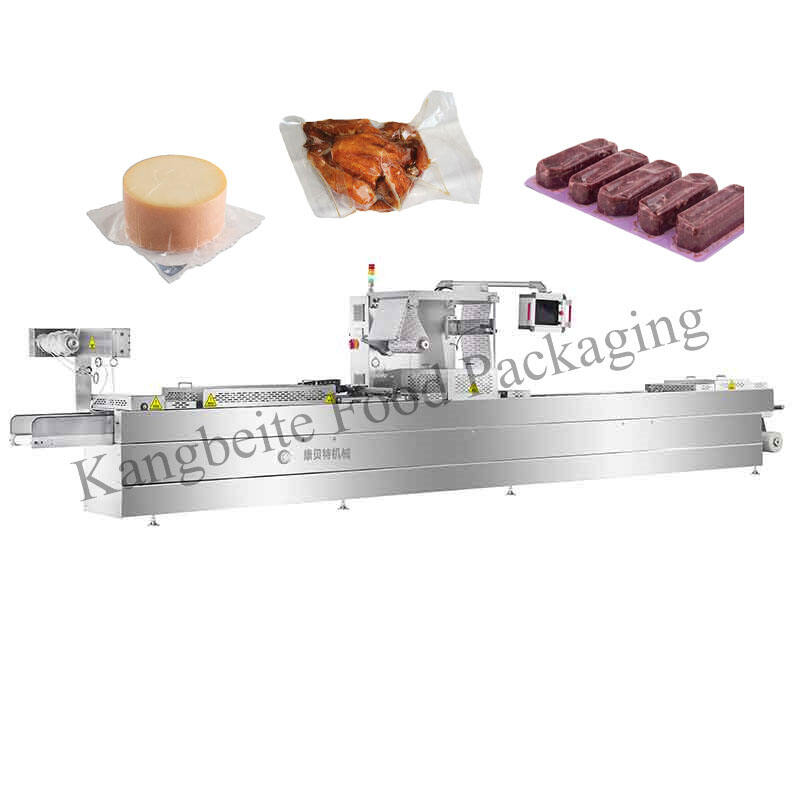

আমাদের মাল্টি-পার্পস থার্মোফর্মিং সরঞ্জামগুলি প্যাকেজিংয়ের বিস্তৃত প্রয়োজনের জন্য একটি বহুমুখী এবং উদ্ভাবনী সমাধান। এই যন্ত্রপাতি বিভিন্ন ধরনের প্লাস্টিকের উপাদান পরিচালনা করতে এবং বিভিন্ন আকার এবং আকারের প্যাকেজ তৈরি করতে ডিজাইন করা হয়েছে, যা খাদ্য পণ্য থেকে গ্রাহক পণ্য পর্যন্ত সবকিছু প্যাকেজ করার জন্য উপযুক্ত। থার্মোফর্মিং প্রক্রিয়াতে প্লাস্টিকের শীট গরম করা, একটি ছাঁচ ব্যবহার করে এটিকে পছন্দসই আকৃতিতে গঠিত করা এবং তারপরে অতিরিক্ত উপাদানটি কাটা জড়িত। আমাদের মাল্টিপপ্লাস সরঞ্জামগুলি ছাঁচ তৈরির ক্ষেত্রে নমনীয়তা প্রদান করে, যা পণ্যটির আকর্ষণীয়তা এবং কার্যকারিতা বাড়াতে পারে এমন কাস্টম-আকৃতির প্যাকেজ তৈরির অনুমতি দেয়। এটি উন্নত তাপমাত্রা নিয়ন্ত্রণ ব্যবস্থা দিয়ে সজ্জিত, যা ধারাবাহিক গঠনের ফলাফলের জন্য সুনির্দিষ্ট গরম এবং শীতলতা নিশ্চিত করে। স্বয়ংক্রিয়ভাবে খাওয়ানো এবং ট্রিমিং প্রক্রিয়াগুলি হস্তমৈথুনের কাজ হ্রাস করে এবং উপাদান অপচয়কে কমিয়ে আনার মাধ্যমে উৎপাদনশীলতা বৃদ্ধি করে। উপরন্তু, আমাদের বহুমুখী তাপীয় কাঠামো বিভিন্ন বিকল্প বৈশিষ্ট্যগুলির সাথে সংহত করা যেতে পারে, যেমন বর্ধিত বালুচর জীবন জন্য গ্যাস ফ্লাশিং, ব্র্যান্ডিং জন্য মুদ্রণ, এবং অতিরিক্ত চাক্ষুষ আবেদন জন্য এমবসডিং। ব্যবহারকারীর জন্য সহজ ইন্টারফেস এবং সহজেই পরিবর্তনযোগ্য ছাঁচ সিস্টেমের মাধ্যমে, এই সরঞ্জামগুলি তাদের প্যাকেজিং বিকল্পগুলি বৈচিত্র্যময় করতে এবং বাজারের পরিবর্তিত চাহিদা পূরণ করতে চায় এমন ব্যবসায়ীদের জন্য একটি ব্যয়বহুল এবং দক্ষ সমাধান সরবরাহ করে।

কপিরাইট © ২০২৫ শান্ডং ক্যানবেইটে ফুড প্যাকেজিং মেশিন কো., লিমিটেড. গোপনীয়তা নীতি