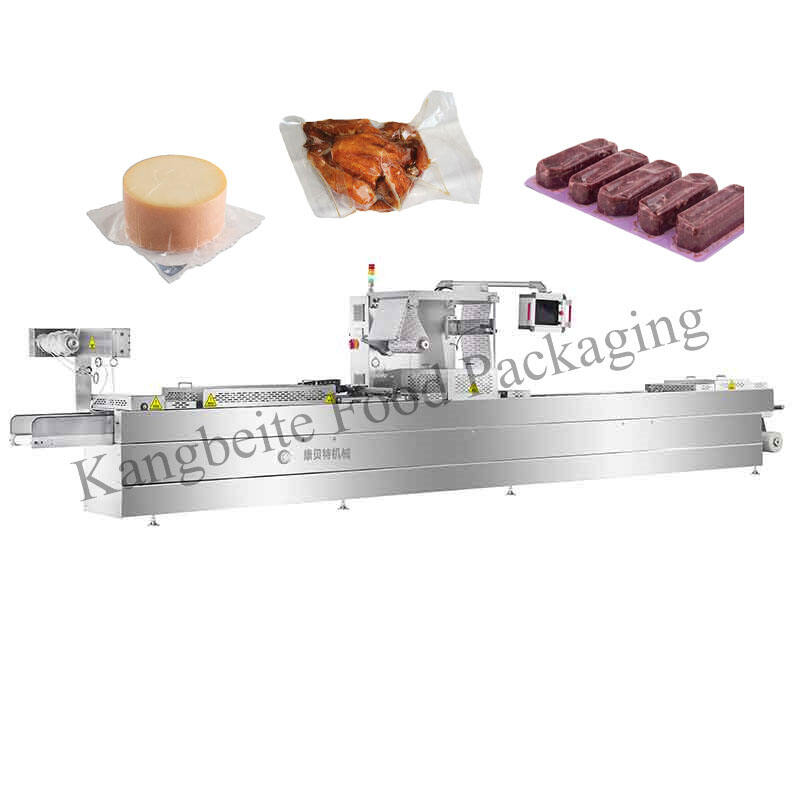

التغليف بالتشكيل الحراري التجاري هو حل شائع وفعال لعدد كبير من الشركات التي تبحث عن طرق لتغليف منتجاتها بشكل جذاب وأمن. تم تصميم حلول التغليف بالتشكيل الحراري التجاري لدينا لتلبية احتياجات الإنتاج بكميات كبيرة للشركات التجارية مع الحفاظ على المعايير الصارمة للجودة. يتضمن عملية التشكيل الحراري تسخين أوراق البلاستيك وتشكيلها إلى حزم مخصصة باستخدام القوالب، والتي يمكن تعديلها وفقًا لمتطلبات المنتجات المختلفة. تتسم آلات التشكيل الحراري التجارية الخاصة بنا بميزات تلقائية متقدمة مثل أنظمة التغذية والتشكيل والتقطيع الآلية، مما يزيد من الإنتاجية ويقلل من تكاليف العمالة. تستطيع هذه الآلات التعامل مع أنواع مختلفة من مواد البلاستيك بما في ذلك PET وPP وPVC، ويمكنها إنتاج حزم بأحجام وأشكال مختلفة، من عبوات صغيرة إلى صواني كبيرة. استخدام القوالب عالية الجودة يضمن نتائج تشكيل دقيقة ومتسقة، بينما تعمل تقنية الختم المتقدمة على إنشاء ختم محكم يحمي المنتجات داخل الحزمة. كما تقدم حلول التغليف بالتشكيل الحراري التجارية لدينا خيارات لإضافة ميزات مثل الطباعة والنحت والتهوية بالغاز، مما يمكن أن يعزز جاذبية المنتج ويمد فترة صلاحيته. وبفضل عملياتهم السريعة والموثوقة والمتنوعة، تعد حلول التغليف بالتشكيل الحراري التجارية لدينا الخيار المثالي للشركات في قطاعات مثل الأغذية والمشروبات، والأدوية، والإلكترونيات، والسلع الاستهلاكية.

حقوق النشر © 2025 لمصلحة شاندونغ كانغبيتي لتعبئة الأغذية وآلات التغليف المحدودة. سياسة الخصوصية