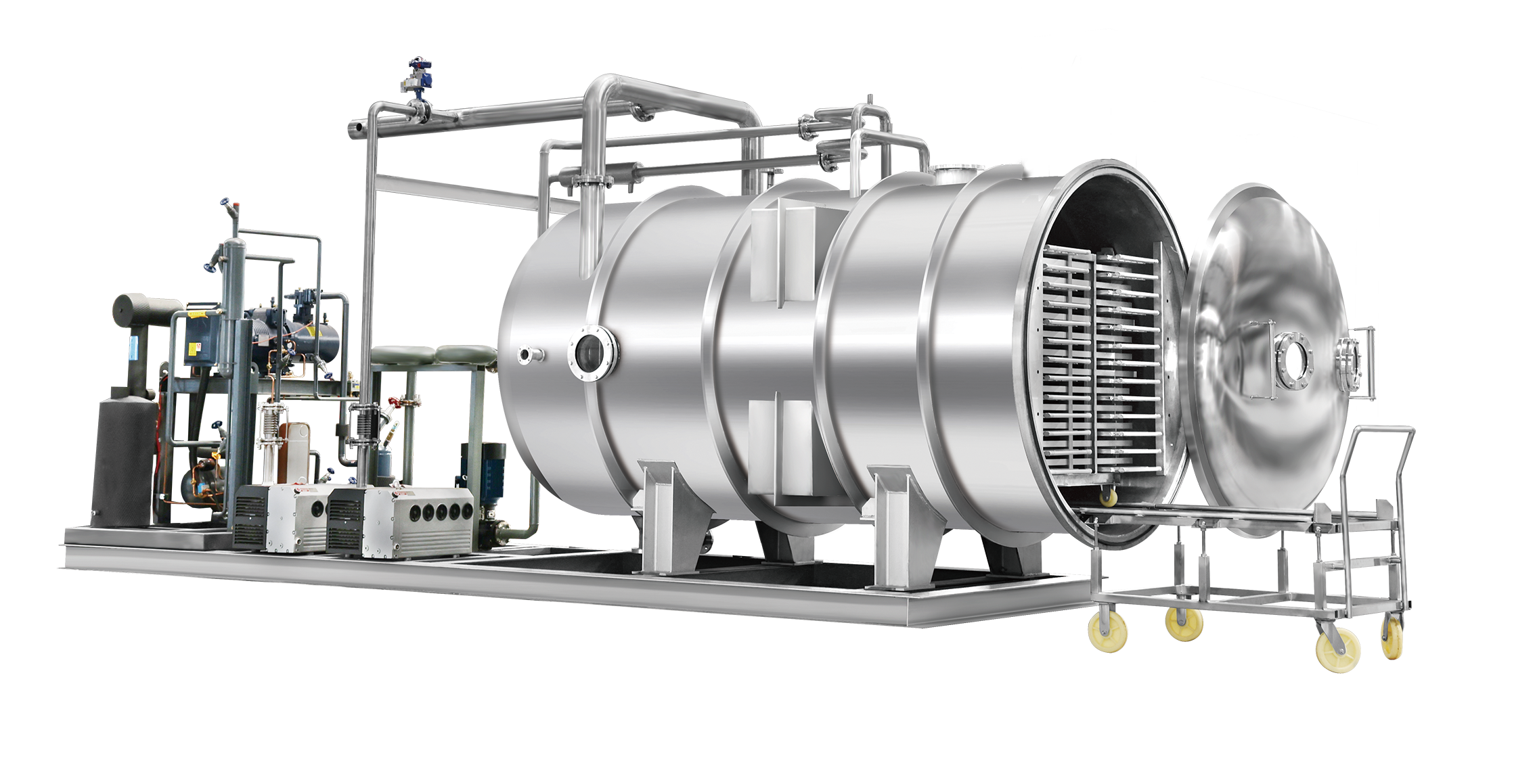

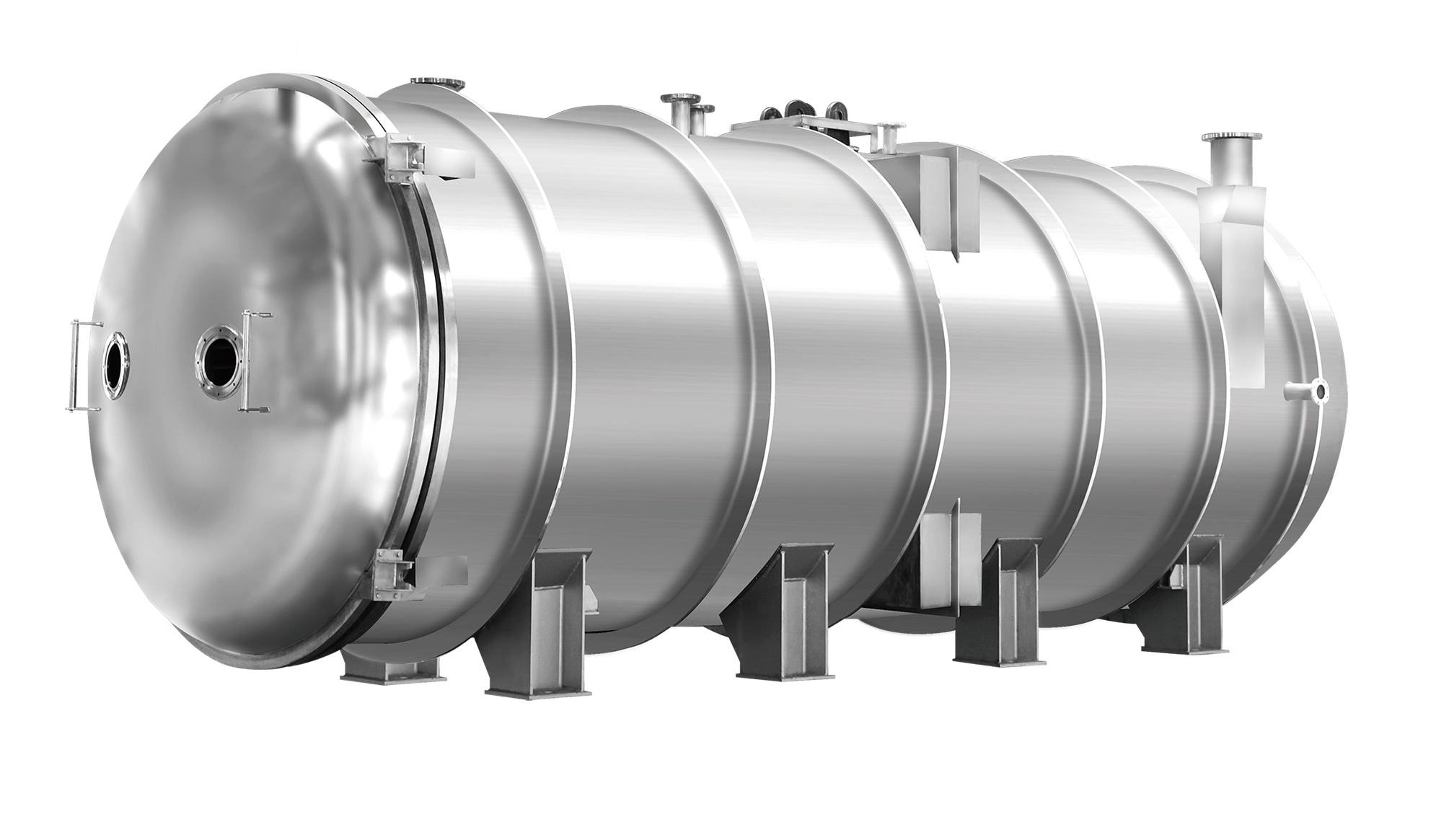

The new coffee production line model represents the latest advancement in coffee manufacturing, integrating cutting edge technology to enhance efficiency, quality, and sustainability. This model incorporates several innovations: automated green bean handling with AI powered sorting systems that use near infrared (NIR) sensors to detect defects, ensuring only premium beans proceed. Roasting modules feature precision temperature control (±1°C) and real time smoke analysis to optimize flavor development, with energy recovery systems that capture waste heat for preheating air, reducing energy consumption by up to 30%. Grinding stations use adjustable burrs with digital calibration, ensuring consistent particle size for uniform extraction, while brewing units employ pressure profiling technology to customize flavor profiles for different coffee origins. For instant coffee production, the line integrates freeze drying or spray drying modules with improved aroma retention systems, capturing volatile compounds during drying and reintroducing them post processing. Sustainability is a focus, with water recycling systems reducing usage by 50% and waste management modules that convert chaff and spent grounds into biofuel. The line is controlled via a centralized IoT platform, allowing remote monitoring, predictive maintenance alerts, and recipe storage for 100+ product variants, enabling quick shifts between whole bean, ground, and instant coffee. Compliance with ISO 14001 (environmental management) and Fair Trade standards ensures ethical production. For coffee producers, this model increases throughput by 20%, reduces waste, and delivers consistent quality, meeting consumer demands for premium, sustainable coffee products in a competitive global market.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy