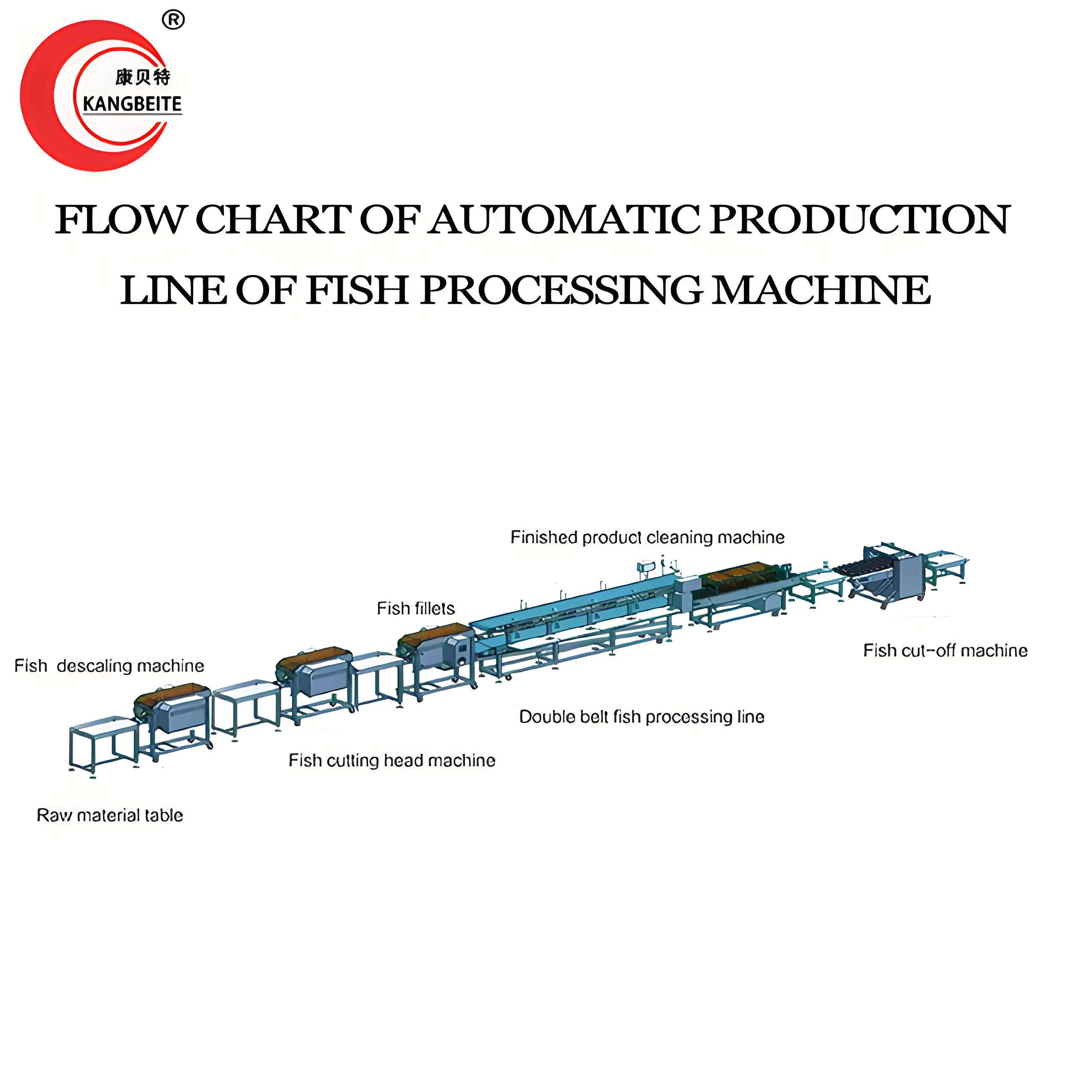

KANGBEITE's fish filleting line is a highly automated and efficient solution designed to streamline the fish filleting process in the seafood processing industry. The line starts with the feeding of whole fish, which is gently transported onto the processing equipment using conveyor belts. The first stage often involves pre processing, such as scaling and gutting (if not already done in separate lines), to prepare the fish for filleting. Advanced fish handling systems ensure that the fish are positioned correctly for the subsequent filleting operations. The filleting process itself is carried out by specialized filleting machines, which use sharp blades and precise cutting mechanisms to separate the fillets from the fish carcass. These machines can be adjusted to handle different types of fish, varying in size and shape, and can achieve high speed filleting while maintaining a high yield of fillets. Some filleting machines are equipped with sensors and vision systems that can detect the bone structure of the fish and adjust the cutting path accordingly, minimizing the amount of bone left in the fillets. After filleting, the fillets are transported to a trimming station, where any remaining bones, skin, or excess fat are removed. The trimmed fillets then pass through a quality inspection area, where they are checked for size, shape, and the presence of any defects. Defective fillets are removed, and the 合格 fillets are further processed, such as being washed, sorted by size, and packaged. The fish filleting line is constructed from food grade stainless steel, which is resistant to corrosion and easy to clean, ensuring compliance with strict food safety standards. With its high efficiency, precision, and ability to handle large volumes of fish, KANGBEITE's fish filleting line is an essential asset for seafood processing plants.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy