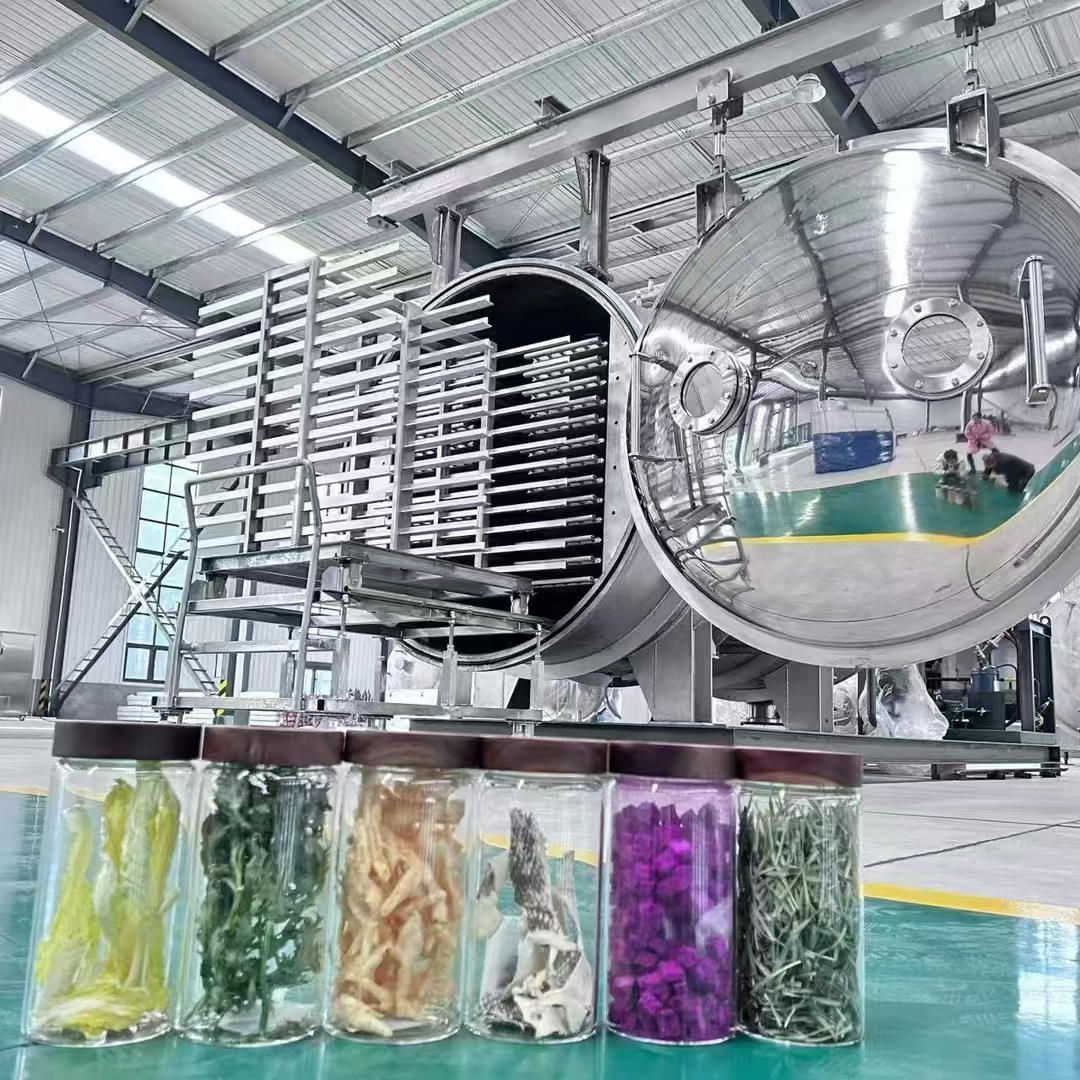

Industrial freeze dryers, also known as lyophilizers, have become indispensable in modern manufacturing across diverse industries. Their core principle—removing moisture from materials through sublimation under vacuum—preserves product quality while extending shelf life, making them crucial in sectors requiring high stability and purity.

In the pharmaceutical industry, industrial freeze dryers dominate the production of injectable drugs, vaccines, and biological products. For instance, COVID-19 vaccines often rely on lyophilization to maintain efficacy during storage and transportation. The process ensures thermal-sensitive compounds remain active, meeting strict regulatory standards for sterility and consistency.

The food and beverage sector increasingly adopts freeze dryers to produce premium products. Dehydrated fruits, instant coffee, and nutritional supplements retain their color, flavor, and nutrients better than traditional drying methods. This technology also enables lightweight, shelf-stable military rations and space foods, appealing to consumers seeking convenience and health.

In biotechnology and research, industrial freeze dryers are vital for preserving cell lines, enzymes, and diagnostic reagents. Laboratories and biopharmaceutical companies use them to maintain sample viability for long-term storage or global distribution, ensuring reproducibility in experiments and clinical trials.

Hot News

Hot News2025-06-26

2025-06-05

2025-06-05

2025-02-12

2025-02-12

2025-02-12

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy