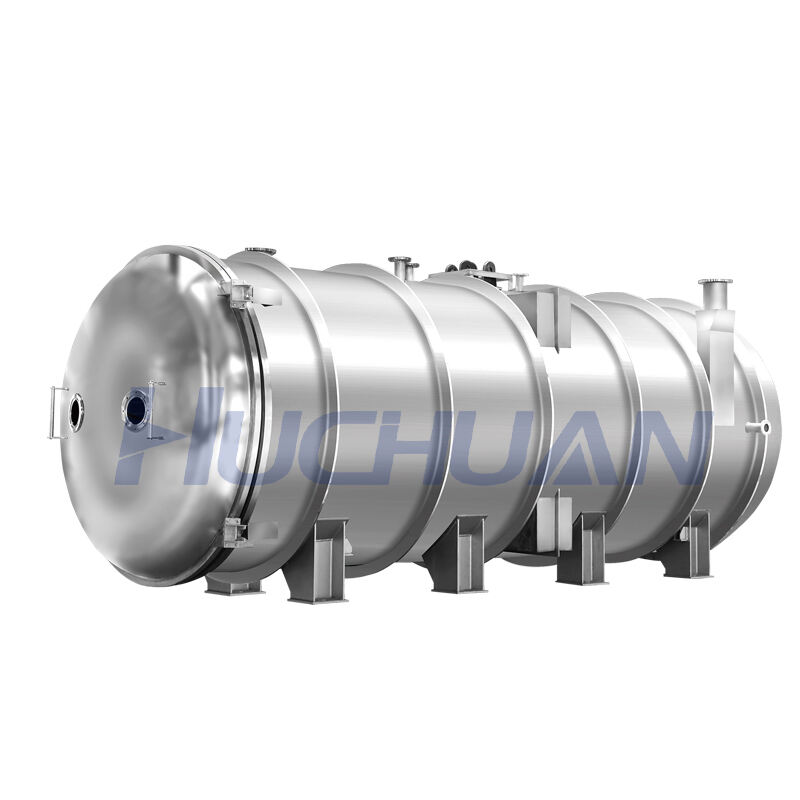

Liofilizator mięsa, czyli suszarka zamarzania, zaprojektowany do przedłużenia okresu przydatności jest specjalistycznym urządzeniem wykorzystującym proces liofilizacji w celu konserwacji produktów mięsnych. Liofilizacja obejmuje zamarzanie mięsa, a następnie zmniejszanie otaczającego ciśnienia, aby poddać lód sublimacji, przekształcając go bezpośrednio w parę, pomijając fazę ciekłą. Ten unikalny proces pozwala zachować wartości odżywcze, smak, teksturę i wygląd mięsa, jednocześnie znacząco przedłużając jego okres przydatności. Liofilizator mięsa rozpoczyna pracę przez umieszczenie produktów mięsnych w komorze suszarki. Następnie komora jest ochładzana do bardzo niskiej temperatury, zwykle znacznie poniżej punktu zamarzania wody, co powoduje, że mięso zamarza całkowicie. Potem ciśnienie wewnątrz komory jest stopniowo obniżane, tworząc środowisko próżniowe. W tej próżni lodu w zamarzniętym mięsie następuje sublimacja, przekształcając się bezpośrednio w parę i uciekając z komory. Ten wolny i kontrolowany proces usuwa wilgoć z mięsa bez uszkodzenia jego struktury komórkowej. W wyniku tego mięso zachowuje swoje pierwotne właściwości i może być przechowywane przez długie okresy bez chłodzenia lub zamarzania. Liofilizator mięsa wyposażony jest w zaawansowane systemy kontroli temperatury i ciśnienia, które gwarantują dokładne i spójne warunki suszenia. Może obsługiwać różne rodzaje mięsa, w tym wołowinę, wieprzowinę, drobiu i mięso łowieckie, oraz produkty na bazie mięsa, takie jak kiełbasy i bekon. Dzięki swojej zdolności do konserwacji mięsa przez dłuższy czas, zachowując jego jakość, liofilizator mięsa jest cennym aktywem dla producentów, fabrykantów i dystrybutorów mięsa, którzy chcą rozszerzyć swój zasięg rynkowy, zmniejszyć marnotrawstwo i oferować wysokiej jakości, trwałe produkty konsumentom.

Prawa autorskie © 2025 Shandong Kangbeite Food Packaging Machine Co., Ltd. Polityka prywatności