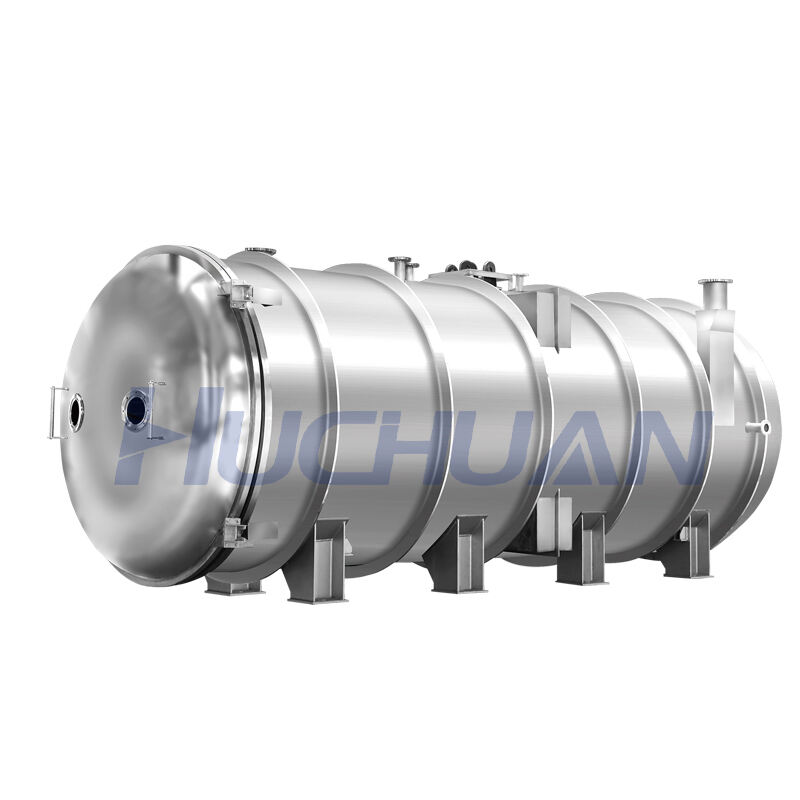

This vacuum lyophilizer is an example of leading technology in the field of freeze-drying. Its highly efficient vacuum pumps can create and maintain the low-pressure environment needed for sublimation at an astonishing speed, further improving the drying time. The embedded smart control system also provides a means to control and maintain the preset values of temperature, pressure, and drying time, to be held for an acceptable range. This guarantee ensures that any product will be freeze-dried under the best possible environment to sustain functionality and integrity. In pharmaceutical research, food processing, or materials science, this appliance makes a mark in its performance, reliability, and versatility like no other.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy