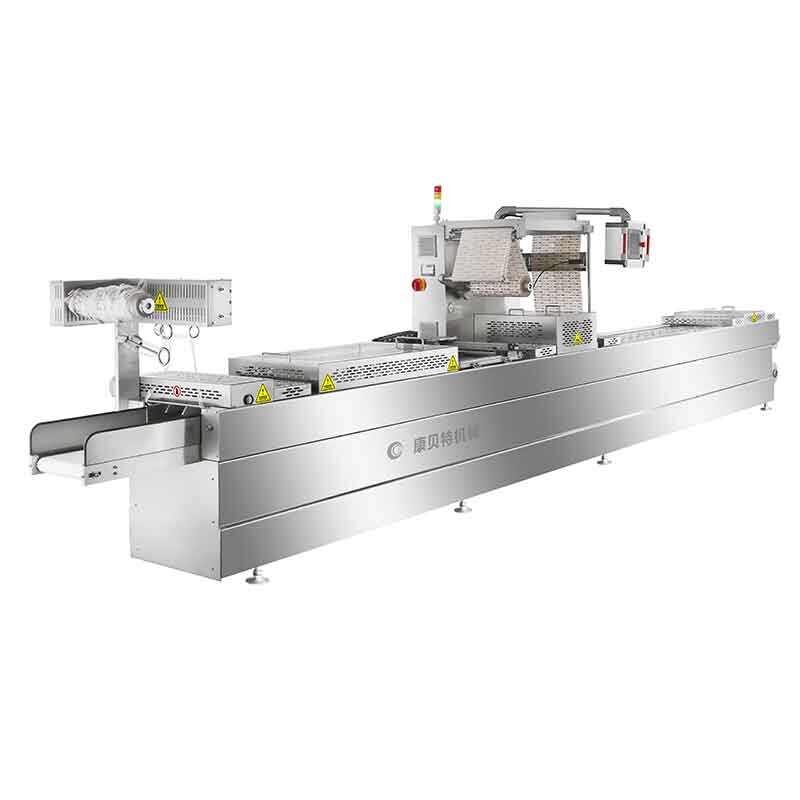

फलहरूको संवेदनशील प्रकृतिको लागि तयार, KANGBEITEका थर्मोफॉर्मिङ व्रैपर्सले नरम तरीकाले पनि प्रभावशील पैकेजिङ समाधान प्रदान गर्छ। यी मशीनहरूले ताजा फलहरू, बेरीहरू र कटिएका उत्पादहरूलाई ध्यानसहित रूपमा ह्यान्दा, चिड़ियाको घाटिबाट न्यूनतम रूपमा बचाउँदै उत्पादको अखण्डता बनाइन्छ। थर्मोफॉर्मिङ प्रक्रियाले फलहरूलाई सुरक्षित रूपमा धेराउने रिज बनाउने ट्रे बनाउँछ, जबकि वैकल्पिक MAP क्षमताले ऑक्सीजन र कार्बन डाइऑक्साइडको स्तर समायोजन गरेर शेल्फ जीवन बढाउँछ। मुख्य विशेषताहरूमा क्षति रोक्ने लागि माइला स्पर्श बनाउने फॉर्मिङ टूलहरू, फिल्मको अनुसार ठुल्लो तापमात्रा नियन्त्रण, र विभिन्न फल टेक्स्चरहरूलाई समायोजन गर्ने समायोजन गरिएको सीलिङ दबाव शामिल छ। व्रैपर्सले उच्च गति उत्पादन समर्थन गर्छ, केही मॉडेलहरू 30 साइकिल प्रति मिनेटसम्म पुग्छ, जसले महत्वपूर्ण फल पैकेजिङ संचालनको लागि आदर्श छ। यी बायोडिग्रेडेबल वा कम्पोस्टेबल फिल्म प्रसेस गर्न सक्छन्, जसले वातावरण सहज पैकेजिङ रुझानहरूसँग मिल्दछ। विशेष गुणस्तर नियन्त्रण प्रणालीहरू लाइनमा राखिएका छन्, जसले सीलिङ अखण्डता र ट्रे बनाउने जाँच गर्दछ, जसले प्रत्येक पैकेजलाई ठोस मानदण्डहरूमा अनुरूप बनाउँछ। KANGBEITEका फल थर्मोफॉर्मिङ व्रैपर्सहरूले दक्षता, उत्पाद सुरक्षा र वातावरण मित्र पैकेजिङ विकल्पहरूमा सन्तुलन बनाउने क्षमताको लागि मुख्य उत्पाद प्रदाताहरूबाट भरोसा पाएको छ।

अधिकार © 2025 शांडोंग कैंगबेटे फूड पैकेजिंग मशीन कम्पनी, लिमिटेड. गोपनीयता नीति