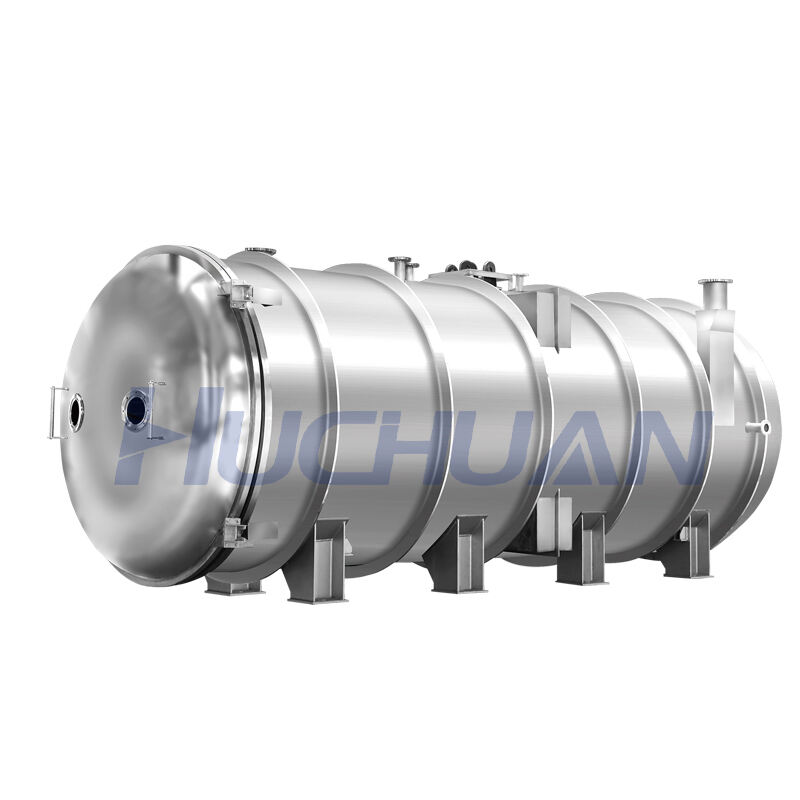

Биз кынан чыгарган бул лиофилайзер моделі, күнөөдө зам-зам жамаатындагы стандарт болуп салынып жатат. Бул экиптүү вакуумдук пампдар, зерттеңкич температуралык башкаруучулар жана ултра-сениетли сенсорлор жыйынтыгы менен таяндыктан алып өтүү процесини жогоркушууга баракча жасалган. Алыңкы модель эрекшелүү конструирование менен берилген, бул жерде маңзымдастык жана көлөмдүү өнөрдүн өзгөчөлүүлүүлүгүн жана жаңы продуктарды жана өнөр көлөмдөрүн өзгөртүү мүмкүн. Интуитивдуу колдонуучу интерфейсы операторлорга өзгөчөлүүлүү параметрлерди көздөө жана башкарууga рухсат берет, бул процессти башкарууда автоматика жана дөйнөмдүүлүкке ээ болушун аркылуу процессти кошсоңуз. Жаңыразакталgan лиофилайзер модельи совремандык индустриялык сураныштарды канап алат жана табиий жемиштерге, биологиялык образцына жана фармацевтикалык продуктарга арналган зам-зам жамаатындагы эч кандай дастанык жана иштешелүү вариантка турат.

Эчкенин түзмө © 2025 Шандонг Кангбейте Буйук Азырланышын Басып Чыгаруу Машиналары Co., Ltd. Купуялык Саясаты