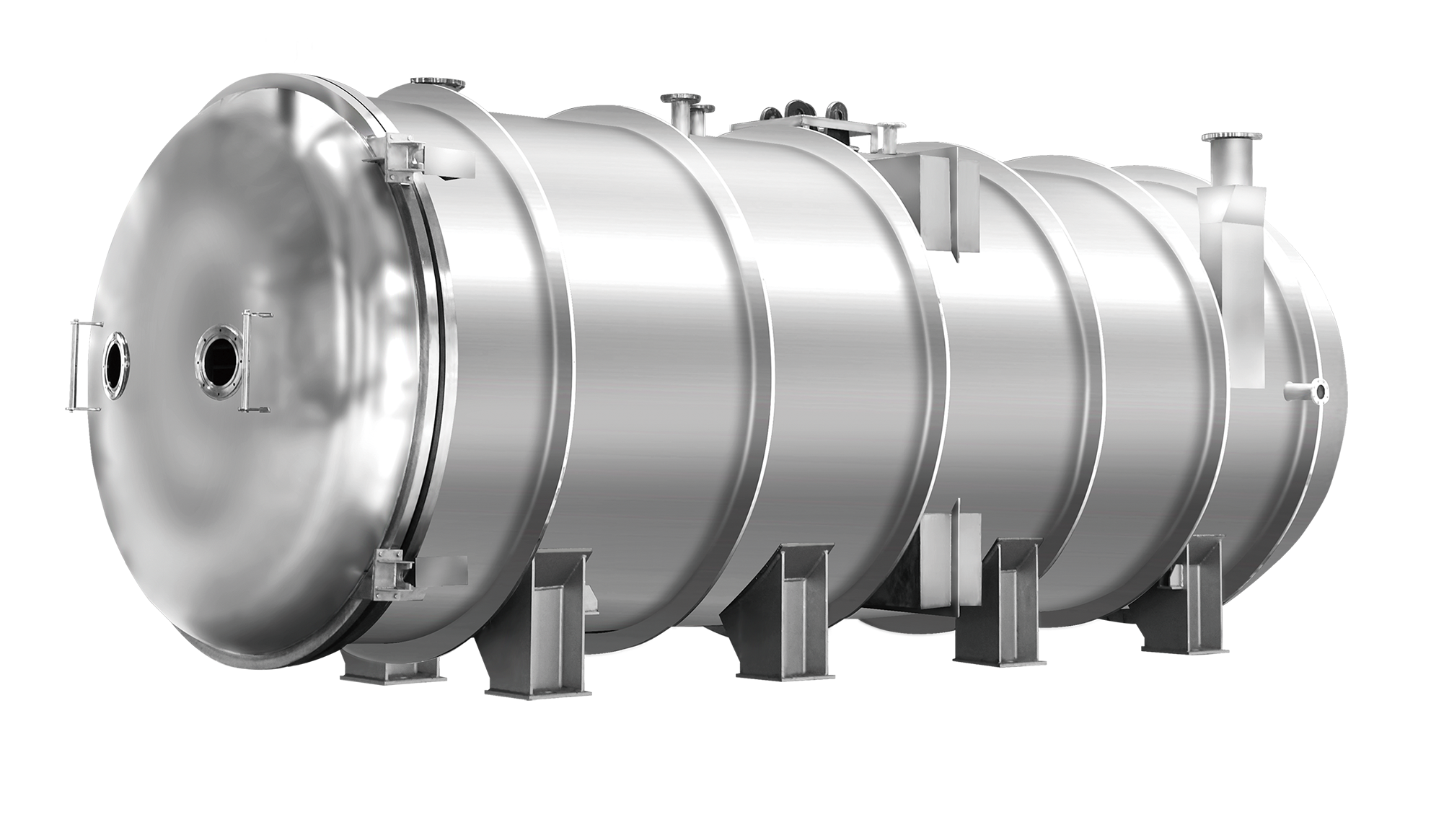

KANGBEITE-ov vakuumni liserni sušilac je napredan uređaj koji se koristi za čuvanje različitih proizvoda kroz proces liofilizacije. Rad vakuumnog lisernog sušioca počinje zamišljivanjem proizvoda. Proizvod se stavlja u sušionu komoru, a temperatura se smanjuje ispod tačke zamišljanja vode, obično na 40°C ili niže, ovisno o prirodi proizvoda. Ovaj brzi proces zamišljanja pomaže da se sačuva struktura i integritet proizvoda. Nakon što se proizvod zamori, aktivira se vakuumski sistem, stvarajući niskopritisnu atmosferu unutar komore. U ovom vakuumu, led u zamorenom proizvodu sublimira iz solidne u plinsku fazu, preskačući tekuću fazu. Ovaj proces sublimacije uklanja vlagu iz proizvoda bez značajnog štetovanja njegovoj ćelijskoj strukturi, ukusu, boji ili nutritivnoj vrijednosti. Vakuumni liserni sušilac je opremljen kondenzatorom koji uhvata vlažnu paru sublimiranu iz proizvoda, pretvarajući je natrag u led za jednostavno uklanjanje. Proces sušenja je pažljivo kontrolisan sofisticiranim sistemom kontrole temperature i vakuumskog pritiska. Operatori mogu postaviti specifične profile sušenja na osnovu zahteva različitih proizvoda, prilagođavajući parametre kao što su temperatura, vakuumski pritisak i vreme sušenja. Mašina je izgrađena od higijenskih materijala od nerdzavajuće ocele klase za hrano, osiguravajući higijenu i sigurnost, posebno za primjenu u prehrani i farmaceutskim proizvodima. Također ima lako čistive površine i brzo pristupačne vrata za održavanje. Zahvaljujući svojoj sposobnosti da proizvodi visokokvalitetne proizvode sa dugim rokom čuvanja, KANGBEITE-ov vakuumni liserni sušilac široko se koristi u industrijama poput prerade hrane, farmaceutske, biotehnologije i kosmetike.

Autorska prava © 2025 Shandong Kangbeite Food Packaging Machine Co., Ltd. Pravilo o privatnosti