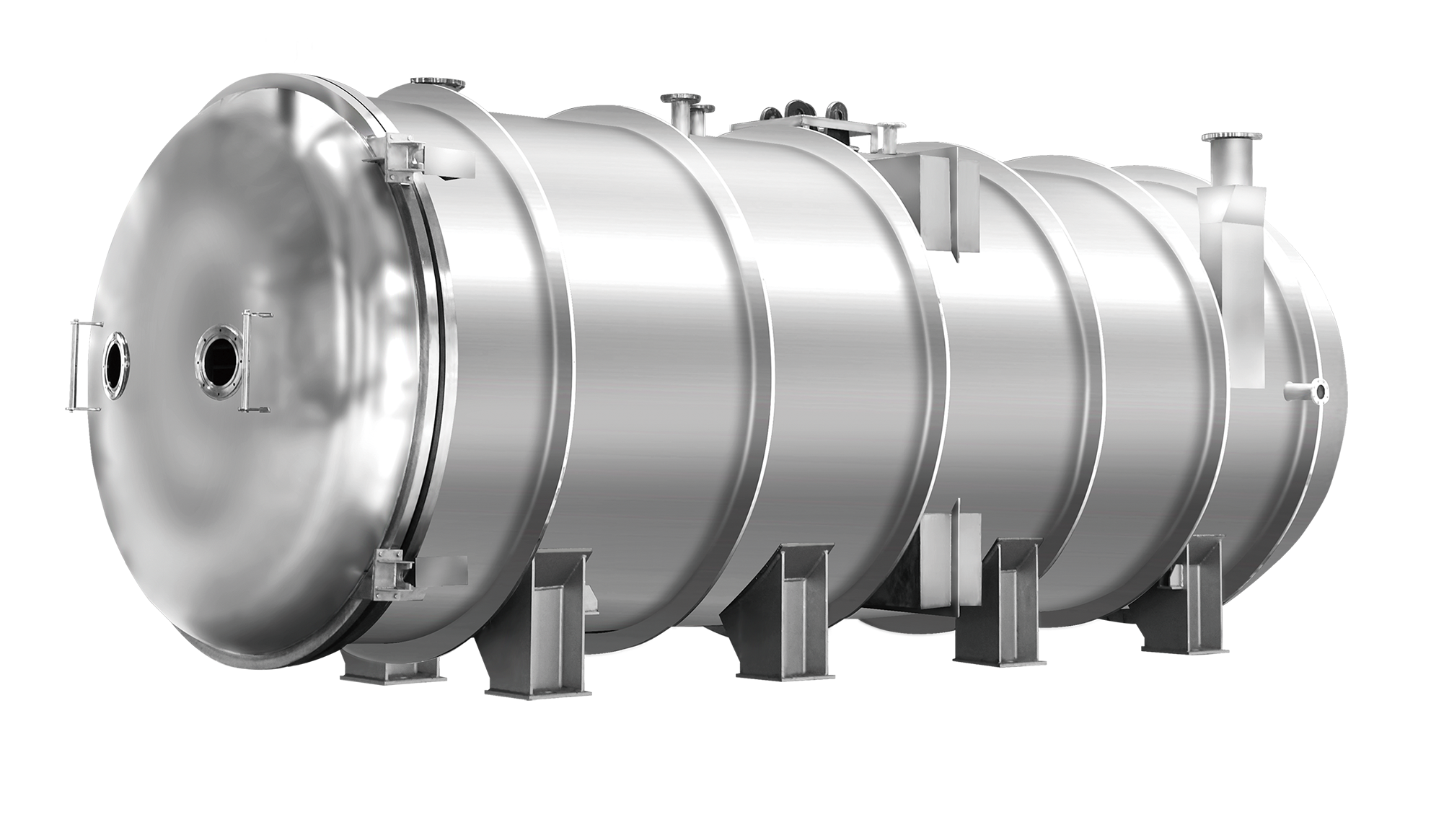

KANGBEITE's vacuum freeze dryer is a state of the art piece of equipment used for the preservation of various products through the process of lyophilization. The operation of the vacuum freeze dryer begins with the freezing of the product. The product is placed in the drying chamber, and the temperature is lowered to well below the freezing point of water, typically to 40°C or lower, depending on the nature of the product. This rapid freezing process helps to preserve the structure and integrity of the product. Once the product is frozen, the vacuum system is activated, creating a low pressure environment inside the chamber. Under this vacuum, the ice in the frozen product sublimes directly from a solid to a gas, bypassing the liquid phase. This sublimation process removes the moisture from the product without causing significant damage to its cellular structure, flavor, color, or nutritional value. The vacuum freeze dryer is equipped with a condenser, which captures the water vapor sublimated from the product, converting it back into ice for easy removal. The drying process is carefully controlled by a sophisticated temperature and vacuum control system. Operators can set specific drying profiles based on the requirements of different products, adjusting parameters such as temperature, vacuum pressure, and drying time. The machine is constructed with food grade stainless steel materials, ensuring hygiene and safety, especially for food and pharmaceutical applications. It also features easy to clean surfaces and quick access doors for maintenance. With its ability to produce high quality, long shelf life products, KANGBEITE's vacuum freeze dryer is widely used in industries such as food processing, pharmaceuticals, biotechnology, and cosmetics.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy