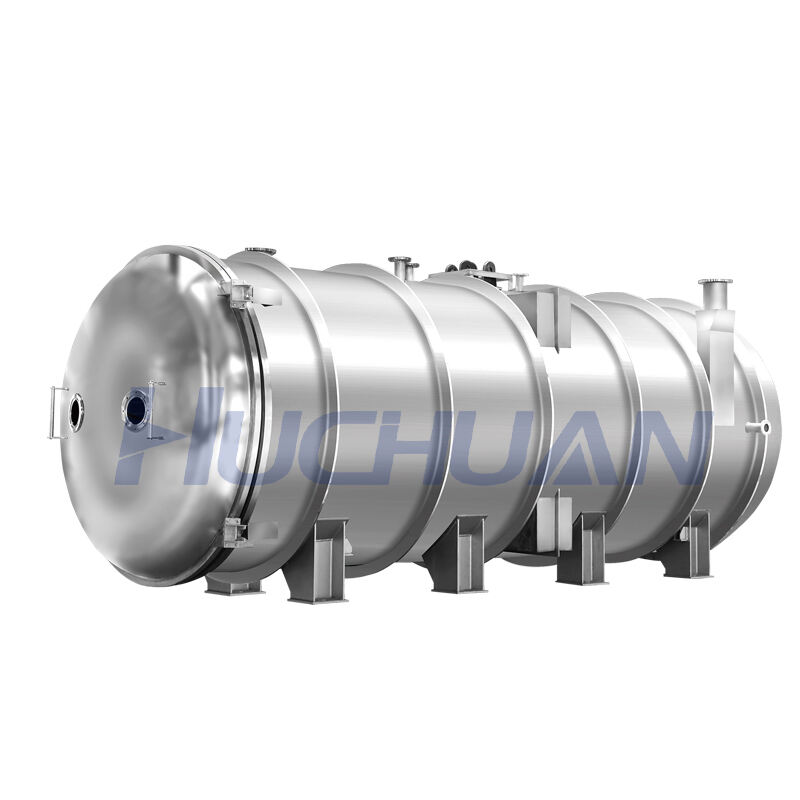

Fulfilling the exact requirements of food preservation, our food-grade lyophilizer is designed to meet industry standards. It contains no non-food grade materials which may pose a contamination risk. The shine and smoothness of the surfaces and interiors of the lyophilizer enable easy sanitation. Using modern technology, our food grade lyophilizer uses advanced freeze-drying techniques to remove water without damaging the food’s vitamins, nutrients, and natural flavors. You can trust this lyophilizer to flawlessly process fruits, vegetables, meats, and dairy products.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy