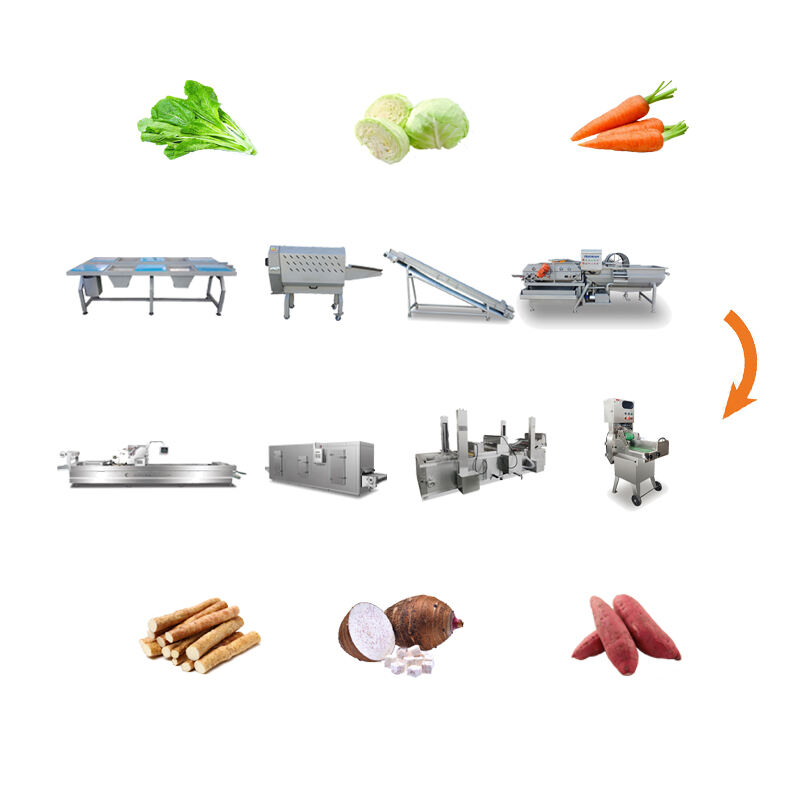

Industrial Vegetable Washers: Dependable Cleaning Solutions for Industry Use

Meeting the demands of restaurants, grocery stores, and fruit – processing enterprises is made easy with our commercial fruit washers. With easy maintenance, reliable performance, and efficient cleaning, customers are served with fresh and clean fruits.

Get A Quote