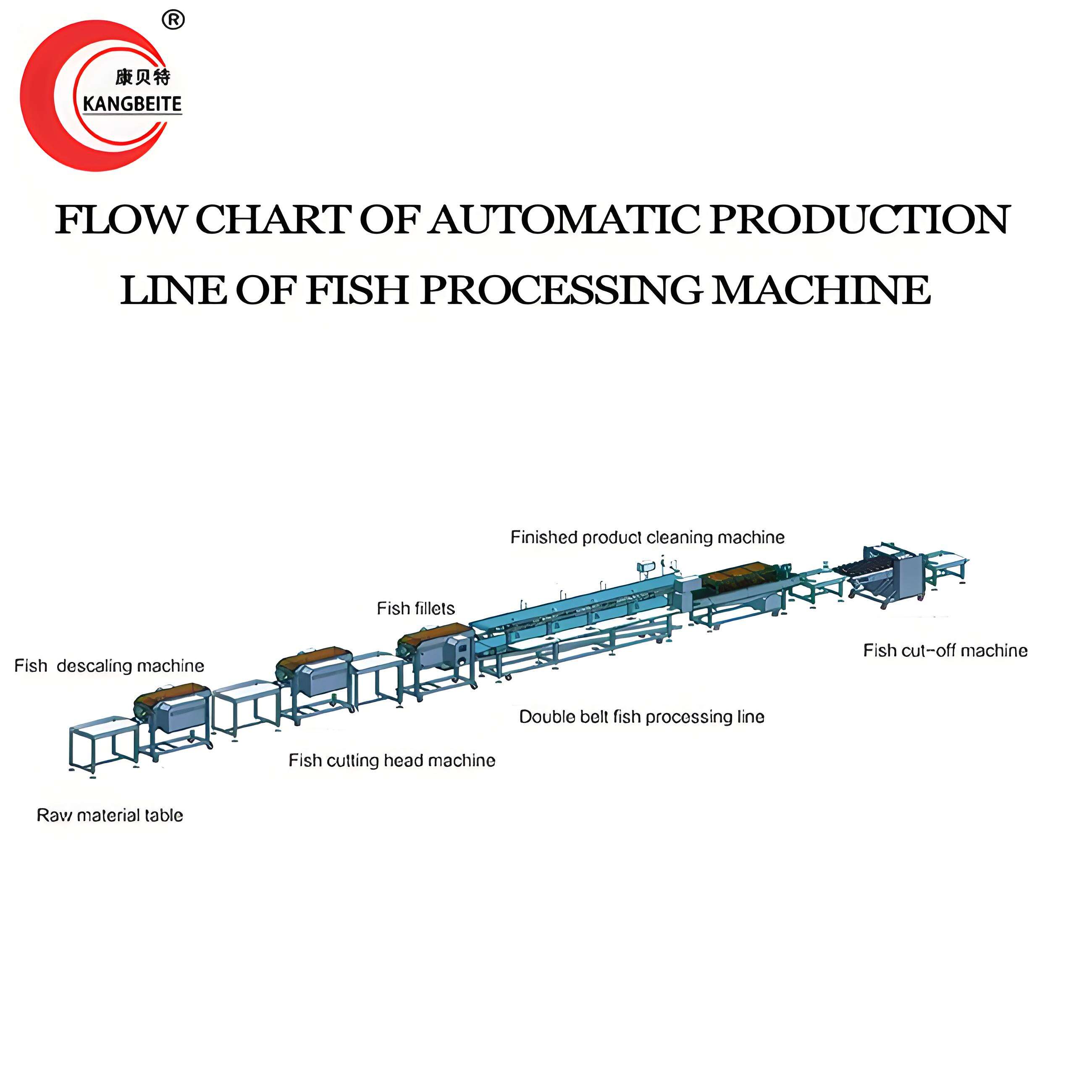

KANGBEITE's automatic fish processing line is a cutting edge solution designed to revolutionize the seafood processing industry by maximizing efficiency and minimizing manual labor. This fully automated line encompasses the entire fish processing workflow, from the moment raw fish enters the facility to the production of finished products. At the start, fish are fed onto a conveyor system, which transports them through a series of automated stations. The first station typically involves sorting, where advanced optical sorting machines equipped with high resolution cameras and intelligent algorithms analyze the fish's size, shape, color, and quality. These machines can quickly separate fish into different categories, ensuring that each batch is processed according to its specific requirements. Next, the scaling process is carried out using automated scaling machines. These machines utilize a combination of mechanical and water jet technologies; high speed rotating brushes or blades, along with precisely controlled water jets, work in harmony to remove scales from all parts of the fish, including hard to reach areas. Following scaling, the fish move to the gutting and cleaning stations. Automatic gutting machines with sharp, adjustable blades make precise incisions to remove the internal organs, while integrated water flushing systems thoroughly clean the abdominal cavity. The waste generated during these processes is automatically collected and removed by an integrated waste management system. In the filleting stage, the line features state of the art filleting machines. These machines are equipped with advanced sensors and robotic arms that can accurately detect the bone structure of the fish and make precise cuts to separate the fillets. Some models even use computer vision technology to adapt to different fish shapes and sizes, ensuring high quality fillets with minimal waste. After filleting, the fillets are automatically trimmed, washed, and sorted by size. The final stage of the automatic fish processing line is packaging. Depending on the product type, the line can be integrated with various packaging machines, such as vacuum packaging machines, tray sealing machines, or canning lines. These packaging machines are also automated, with features like automatic bag feeding, filling, sealing, and labeling. The entire automatic fish processing line is controlled by a central PLC (Programmable Logic Controller) system, which coordinates the operation of all components, monitors process parameters in real time, and makes adjustments as needed to ensure consistent product quality and high speed production. With its advanced technology and seamless automation, KANGBEITE's automatic fish processing line is the ideal choice for large scale seafood processing plants aiming to enhance productivity and reduce costs.

Copyright © 2025 by Shandong Kangbeite Food Packaging Machine Co., Ltd. Privacy policy